This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

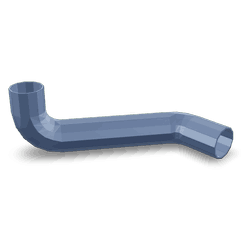

The Cummins 3349106 Elbow Hose is a component designed for use in commercial trucks, playing a role in the fluid systems of these vehicles. It is manufactured by Cummins, a company with a strong reputation in the automotive industry for producing reliable and high-quality parts. This hose is integral to the efficient operation of trucks, ensuring that fluids are transported effectively throughout the vehicle’s systems.

Basic Concepts of Elbow Hoses

An elbow hose is a type of hose that features a bend, allowing it to navigate around obstacles or fit into tight spaces within a vehicle’s fluid system. These hoses are used to connect different components, facilitating the flow of fluids such as coolant, fuel, or hydraulic fluid. In the context of a truck’s systems, elbow hoses enable the routing of fluids in a manner that accommodates the complex layout of the vehicle’s engine compartment and other areas 1.

Purpose and Function of the 3349106 Elbow Hose

The Cummins 3349106 Elbow Hose is designed to play a specific role within a truck’s fluid systems. It is used to connect components that require a bend in the hose to achieve proper alignment and function. This hose handles various fluids depending on its application within the truck, connecting systems such as the engine cooling system, fuel system, or hydraulic systems. Its purpose is to ensure a secure and efficient transfer of fluids, contributing to the overall performance and reliability of the truck.

Key Features

The Cummins 3349106 Elbow Hose is constructed with materials that offer durability and resistance to the fluids it carries. Its design includes a specific bend radius that allows it to fit into the intended space within the truck’s system without kinking or restricting flow. The hose is also engineered to withstand the pressures and temperatures associated with its application, ensuring long-term performance and reliability.

Benefits of Using the 3349106 Elbow Hose

Utilizing the Cummins 3349106 Elbow Hose offers several advantages. Its design contributes to improved fluid flow within the truck’s systems, reducing the risk of leakage and enhancing overall system efficiency. The durability of the hose ensures that it can withstand the demands of commercial truck operations, providing a reliable component for fluid transport.

Installation Considerations

When installing the Cummins 3349106 Elbow Hose, it is important to follow guidelines and best practices to ensure proper fit and function. Compatibility with other components should be verified, and the necessary tools and procedures should be used to secure the hose in place. Careful attention to the routing of the hose will help prevent kinks or obstructions that could impede fluid flow.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3349106 Elbow Hose is important to ensure its longevity and efficiency. This includes checking for signs of wear or damage, ensuring connections are secure, and replacing the hose if necessary. Common issues that may arise include leaks or reduced fluid flow, which can often be addressed by inspecting the hose and connections, and making repairs or replacements as needed.

Safety Considerations

When working with the Cummins 3349106 Elbow Hose, it is important to observe safety practices. This includes handling fluids with care to avoid spills or exposure, and ensuring that the hose is properly installed to prevent leaks or failures. Following manufacturer guidelines and using the appropriate tools and procedures will help ensure a safe and effective installation and maintenance process.

Cummins: A Brief Overview

Cummins is a well-regarded manufacturer in the automotive industry, known for its commitment to quality and innovation. The company offers a wide range of products designed for various applications, including commercial trucks. Cummins’ reputation is built on a history of producing reliable and high-performance parts, contributing to the efficiency and durability of the vehicles they are used in 2.

Role of Part 3349106 Elbow Hose in Heat Exchanger Systems

In heat exchanger systems, the 3349106 Elbow Hose plays a significant role in ensuring efficient fluid dynamics and thermal management. This component is integral to the system’s ability to transfer heat between fluids without them mixing.

Functionality in Heat Exchanger Systems

-

Fluid Routing: The 3349106 Elbow Hose is designed to route coolant or other fluids through the heat exchanger. Its angled design allows for a smooth transition between straight sections of hose, minimizing turbulence and pressure drop. This ensures consistent fluid flow, which is essential for maintaining the efficiency of the heat transfer process 3.

-

Thermal Efficiency: By facilitating a streamlined flow path, the elbow hose helps in reducing the likelihood of hotspots within the heat exchanger. This uniform distribution of fluid enhances the overall thermal efficiency of the system, allowing for optimal heat exchange between the hot and cold fluids.

-

System Integration: The elbow hose is often connected to various components within the heat exchanger, such as the inlet and outlet ports, as well as other hoses and fittings. Its role in integrating these components ensures a cohesive and functional system, where each part works in harmony to achieve the desired thermal performance.

-

Maintenance and Accessibility: The design of the 3349106 Elbow Hose also contributes to the ease of maintenance. Its placement allows for straightforward access during inspections or replacements, which is vital for the longevity and reliability of the heat exchanger system.

Conclusion

In summary, the 3349106 Elbow Hose is a key component in the effective operation of heat exchanger systems, contributing to fluid dynamics, thermal efficiency, system integration, and maintenance accessibility.

-

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.