This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3067575 Flexible Hose is a vital component in commercial trucks, designed to facilitate the transfer of fluids within the truck’s systems. This ensures efficient operation and reliability, contributing to the performance and longevity of the truck’s fluid systems.

Basic Concepts of Flexible Hoses

Flexible hoses are essential in automotive applications for connecting various components within a system, allowing for the transfer of fluids such as coolant, fuel, or hydraulic fluid. These hoses are designed to accommodate movement and vibration, common in vehicle operations, thereby reducing the risk of damage or failure. They provide a flexible conduit that can bend and twist without compromising fluid flow 1.

Purpose of the 3067575 Flexible Hose

The Cummins 3067575 Flexible Hose connects critical components within the fluid systems of a truck. It transports fluids between parts that may move relative to each other, such as the engine and radiator in a cooling system. This ensures smooth fluid flow despite the dynamic environment within the truck.

Key Features

The Cummins 3067575 Flexible Hose is constructed from high-quality materials that offer resistance to wear and tear, as well as extreme temperatures. Its flexibility allows it to bend and twist without kinking, accommodating the movement of connected components. The hose’s design specifications ensure a secure fit and reliable connection within the truck’s systems.

Benefits

Using the Cummins 3067575 Flexible Hose offers several advantages. Its improved flexibility reduces the likelihood of damage from movement and vibration. The hose’s design minimizes the risk of leaks, ensuring secure and efficient fluid transfer. Enhanced durability means it can withstand the harsh conditions typical in commercial truck operations. Furthermore, the ease of installation simplifies maintenance and replacement processes.

Installation Considerations

When installing the Cummins 3067575 Flexible Hose, it is important to consider compatibility with other components within the system. Ensuring a proper fit and secure connection is crucial for optimal performance. Best practices include following manufacturer guidelines for installation, using appropriate tools, and verifying that all connections are tight and free from obstructions.

Troubleshooting Common Issues

Common problems associated with flexible hoses include leaks, cracks, and kinks. To address these issues, regular inspections should be conducted to identify any signs of wear or damage. If a leak is detected, the hose should be replaced to prevent fluid loss and potential system failure. Cracks or kinks may indicate material fatigue or improper installation, necessitating a review of installation practices and possible replacement of the hose.

Maintenance Tips

To ensure the longevity and reliability of the Cummins 3067575 Flexible Hose, regular maintenance practices are recommended. This includes periodic inspections to check for signs of wear, damage, or leaks. Replacement guidelines should be followed to ensure that the hose is changed before it reaches the end of its service life. Additionally, keeping the hose clean and free from debris can help maintain its performance and durability.

Cummins Overview

Cummins Inc. is a well-established company with a rich history in the commercial truck industry. Known for its extensive product range and reputation for quality, Cummins provides a variety of components and systems designed to enhance the performance and reliability of commercial vehicles. The company’s commitment to innovation and customer satisfaction has solidified its position as a leader in the industry.

Role of Part 3067575 Flexible Hose in Engine Systems

The Cummins part 3067575, a Flexible Hose, is designed to integrate seamlessly with several engine models, ensuring efficient fluid transfer and system integrity. This part is particularly compatible with the N14 MECHANICAL and NH/NT 855 engines. In these engines, the flexible hose is crucial for maintaining the fluidity and flexibility needed in high-pressure environments, preventing leaks and ensuring optimal performance.

For the N14 MECHANICAL engine, the flexible hose connects various critical components, facilitating the movement of fluids such as coolant and oil. Its design allows for the necessary expansion and contraction due to temperature fluctuations, which is essential in maintaining the engine’s operational efficiency.

Similarly, in the NH/NT 855 engine, the flexible hose is integral to the hydraulic and cooling systems. It ensures that the fluid flow remains uninterrupted, which is vital for the engine’s cooling and lubrication processes. The flexibility of the hose accommodates the engine’s movements and vibrations, preventing wear and tear on the connections.

Both engines benefit from the use of this flexible hose, as it enhances the overall reliability and longevity of the engine systems. The compatibility of the part with these engines underscores its importance in maintaining the integrity of the fluid transfer systems within these engine models 2.

Fuel Systems

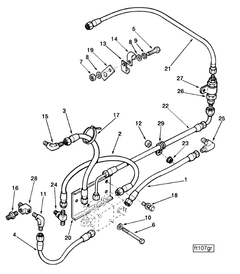

In fuel systems, the Flexible Hose is employed in fuel plumbing and fuel tubing to convey fuel from the fuel supply to the injector. This hose allows for the necessary flexibility to accommodate engine movement and vibrations, maintaining a consistent fuel flow which is essential for engine performance.

Oil Systems

Within the oil system, the Flexible Hose is utilized in conjunction with the oil manifold. It enables the distribution of oil to various engine components, ensuring lubrication and cooling. The hose’s flexibility is particularly beneficial in navigating the complex routing required around the engine block and other components.

Overhaul and Maintenance Kits

The Flexible Hose is often included in overhaul kits and tachometer parts kits. During engine maintenance or overhaul, replacing worn or damaged hoses with the Flexible Hose ensures that the new installation can withstand the dynamic environment of the engine compartment. This contributes to the longevity and reliability of the engine system.

Plumbing and Mounting Steps

The hose is also a key component in the plumb and mounting step, plumbing step, and step plumbing and mounting processes. These steps involve the precise installation of hoses to connect various engine components. The Flexible Hose’s adaptability makes it ideal for these applications, allowing for easier installation and reduced risk of leaks.

Comprehensive Engine Plumbing

Overall, the Flexible Hose plays a significant role in the plumbing of engine systems. Whether it’s connecting the fuel supply to the injector or ensuring proper oil distribution through the oil manifold, this component is essential for the fluid dynamics within the engine. Its use in plumbing and mounting steps further underscores its importance in maintaining the integrity and efficiency of engine systems 3.

Conclusion

The Cummins 3067575 Flexible Hose is a critical component in the efficient operation of commercial truck fluid systems. Its flexibility, durability, and compatibility with various engine models make it an essential part for maintaining the performance and reliability of these systems. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this part in engine applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.