This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3100034 Flexible Hose is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by facilitating the transfer of fluids or gases between various systems. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of truck operations 1.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive systems to transfer fluids or gases under varying conditions. They are designed to accommodate movement and vibration, which are common in vehicle operations 2. These hoses are crucial for connecting different parts of a system that may not be in a fixed position relative to each other, allowing for the efficient transfer of substances without the risk of leaks or damage.

Purpose of the 3100034 Flexible Hose

The Cummins 3100034 Flexible Hose is specifically designed to connect various systems within a truck, transporting fluids or gases as required. It plays a role in ensuring that these substances are moved efficiently and safely throughout the vehicle, contributing to the overall operation and performance of the truck 3.

Key Features

The Cummins 3100034 Flexible Hose is characterized by several key features that enhance its performance and longevity. These include its material composition, which is selected for durability and resistance to the substances it transports. The hose’s flexibility allows it to accommodate the movement and vibration inherent in truck operations, while its design elements ensure a secure fit and efficient transfer of fluids or gases 4.

Benefits

The use of the Cummins 3100034 Flexible Hose offers several benefits. It contributes to improved system reliability by reducing the risk of leaks, which can occur with rigid connections. Its flexibility allows for more efficient routing of hoses within the truck, and its durability ensures resistance to wear and environmental factors, enhancing the overall performance and longevity of the truck’s systems 5.

Installation Considerations

Proper installation of the Cummins 3100034 Flexible Hose is important for its effective operation. Guidelines and best practices include ensuring proper alignment, using appropriate securing methods, and confirming a proper fit within the truck’s system. These steps help to prevent issues such as leaks or disconnections, ensuring the hose functions as intended 6.

Troubleshooting Common Issues

Common problems associated with flexible hoses include leaks, kinks, or degradation over time. Troubleshooting these issues involves inspecting the hose for signs of wear or damage, ensuring it is properly aligned and secured, and replacing it if necessary. Addressing these issues promptly can help maintain the efficiency and safety of the truck’s systems 7.

Maintenance Tips

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 3100034 Flexible Hose. This includes regular inspection intervals to check for signs of wear or damage, cleaning procedures to remove any buildup that could affect performance, and considering replacement when the hose shows significant signs of degradation 8.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. The company’s history and reputation provide context for the quality and performance of the Cummins 3100034 Flexible Hose, reflecting Cummins’ dedication to enhancing the efficiency and reliability of commercial truck operations 9.

Cummins Flexible Hose Part 3100034 in Engine Applications

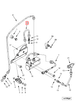

The Cummins Flexible Hose part 3100034 is a critical component in various engine configurations, ensuring efficient and reliable operation. This part is designed to connect different parts of the engine system, allowing for flexibility and movement as the engine operates.

ISX CM570 Engine

In the ISX CM570 engine, the Flexible Hose part 3100034 is integral to the engine’s cooling system. It connects the radiator to the water pump, allowing for the necessary movement and flexibility as the engine heats up and cools down. This hose is designed to withstand high temperatures and pressures, ensuring durability and longevity in demanding conditions 10.

Grouping of Engines

The Flexible Hose part 3100034 is also used in other Cummins engines, particularly those in the same series as the ISX CM570. These engines share similar design principles and operational requirements, making the part compatible across multiple models. The flexibility and durability of this hose make it a versatile component in various engine applications 11.

Role of Part 3100034 Flexible Hose in Engine Systems

The part 3100034 Flexible Hose is integral to the efficient operation of various engine systems. Its primary function is to facilitate the transfer of fluids between components, ensuring seamless operation and maintaining system integrity 12.

Centinel Valve Kit

In the Centinel Valve Kit, the Flexible Hose connects the valve to the main fluid lines. This connection allows for the precise control of fluid flow, which is essential for the valve’s operation. The flexibility of the hose accommodates the movement and vibrations inherent in engine operation, reducing the risk of leaks and ensuring consistent performance 13.

Kit

Within a general kit configuration, the Flexible Hose serves as a versatile connector between various components. Its adaptability makes it suitable for different setups, allowing for easy integration into the engine system. This flexibility ensures that the hose can be routed around obstacles and secured in place without compromising the fluid dynamics 14.

ISX Burn-Only Valve/Mounting

For the ISX Burn-Only Valve/Mounting system, the Flexible Hose plays a key role in connecting the valve to the mounting bracket and the fluid lines. This connection is vital for the valve’s function, which involves regulating the flow of fluids to specific engine components. The hose’s flexibility ensures that it can withstand the thermal expansion and contraction that occur during engine operation, maintaining a secure and leak-free connection 15.

Oil Control Valve

In systems involving an Oil Control Valve, the Flexible Hose is used to connect the valve to the oil supply and return lines. This ensures that the valve can effectively regulate oil flow to various engine parts, optimizing lubrication and cooling. The hose’s flexibility is particularly important in this application, as it must accommodate the dynamic movements of the engine without disrupting the oil flow 16.

Oil Replenishing System

For the Oil Replenishing System, the Flexible Hose is employed to connect the replenishing unit to the main oil lines. This connection allows for the automated addition of oil to the system as needed, maintaining optimal oil levels. The hose’s flexibility ensures that it can be installed in tight spaces and around complex engine components, facilitating efficient oil replenishment 17.

Conclusion

Overall, the part 3100034 Flexible Hose is a vital component in these engine systems, providing the necessary flexibility and reliability to ensure smooth and efficient operation. Its role in facilitating the transfer of fluids between components, accommodating movement and vibration, and ensuring system integrity underscores its importance in maintaining the efficiency and reliability of commercial truck operations 18.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388666, QSK95 CM2350 K113.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388666, QSK95 CM2350 K113.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388666, QSK95 CM2350 K113.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388666, QSK95 CM2350 K113.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4388666, QSK95 CM2350 K113.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.