This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

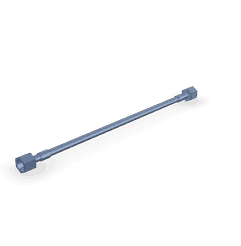

The Cummins 3100073 Flexible Hose Assembly is a component designed for use in commercial trucks. It serves a role in the fluid transfer systems of these vehicles, contributing to their efficient operation. Understanding its purpose and significance is key to maintaining the performance and reliability of commercial trucks.

Basic Concepts of Flexible Hose Assemblies

Flexible hose assemblies are components used in fluid transfer systems to connect various parts of a vehicle’s infrastructure. They are designed to accommodate movement and vibration, which are common in the operation of a truck. These hoses allow for the transfer of fluids such as coolant, fuel, and hydraulic fluid, ensuring that systems operate smoothly and efficiently 1.

Purpose of the 3100073 Flexible Hose Assembly

The 3100073 Flexible Hose Assembly is specifically engineered to connect different systems within a truck and transport fluids between them. It plays a role in maintaining the flow of necessary fluids, which is integral to the operation of the truck’s engine and other systems. The assembly is designed to withstand the pressures and temperatures associated with these fluids, ensuring reliable performance 2.

Key Features

The 3100073 Flexible Hose Assembly is characterized by several features that enhance its performance and longevity. It is composed of materials that provide flexibility and durability, allowing it to withstand the dynamic conditions within a truck’s engine compartment. The design of the assembly includes elements that reduce the transmission of vibration, which can lead to wear and tear on the hose and connected systems 3.

Benefits

The use of the 3100073 Flexible Hose Assembly offers several advantages. Its flexibility allows for greater movement than rigid hoses, which can reduce stress on connections and improve the overall durability of the system. Additionally, the assembly’s design helps to minimize the transmission of vibration, which can contribute to a longer service life. The materials used in its construction provide enhanced resistance to wear and environmental factors, further contributing to its reliability 4.

Installation Considerations

Proper installation of the 3100073 Flexible Hose Assembly is important for ensuring optimal performance and longevity. Guidelines for installation include ensuring that the hose is routed correctly to avoid abrasion and that all connections are secure. It is also important to check for any signs of damage before installation and to follow manufacturer recommendations for torque specifications when tightening connections .

Troubleshooting Common Issues

Common problems associated with flexible hose assemblies include leaks, kinks, and degradation. To address these issues, it is important to regularly inspect the hose for signs of wear or damage. If a leak is detected, the source should be identified and repaired or replaced as necessary. Kinks can often be resolved by rerouting the hose, while degradation may require replacement of the assembly .

Maintenance Tips

Regular maintenance practices can help to prolong the life of the 3100073 Flexible Hose Assembly. This includes routine inspections for signs of wear, damage, or leaks. It is also important to ensure that the hose is properly supported and routed to avoid unnecessary stress. Replacement guidelines should be followed when the assembly shows signs of significant wear or when it reaches the end of its service life .

Safety Precautions

When working with the 3100073 Flexible Hose Assembly, it is important to observe safety measures to avoid injury or damage. This includes wearing appropriate personal protective equipment, ensuring that the vehicle is properly supported, and following all manufacturer recommendations for handling and installation. It is also important to be aware of the fluids being transported by the hose and to take appropriate precautions to avoid contact with skin or eyes .

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. The company has a long-standing reputation in the commercial truck industry for producing high-quality, reliable components. Cummins’ product range includes a variety of parts and systems designed to enhance the performance and efficiency of commercial vehicles.

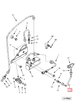

Flexible Hose Assembly Part 3100073 in Cummins Engines

The Flexible Hose Assembly part 3100073, manufactured by Cummins, is a component in several of their engine models. This part is designed to provide flexibility and durability, ensuring smooth operation and longevity of the engine systems it connects.

ISX CM570

In the ISX CM570 engine, the Flexible Hose Assembly part 3100073 is integral to the engine’s cooling system. It connects various coolant lines, allowing for movement and flexibility as the engine operates. This flexibility helps prevent stress and potential damage to the hoses, which can occur due to the constant vibrations and movements of the engine.

CM570

Similarly, in the CM570 engine, the Flexible Hose Assembly part 3100073 plays a role in the engine’s hydraulic and cooling systems. Its design allows it to withstand the high pressures and temperatures typical of these systems, ensuring reliable performance and reducing the risk of leaks or failures.

Grouping of Engines

Both the ISX CM570 and CM570 engines benefit from the use of the Flexible Hose Assembly part 3100073. This part is engineered to meet the specific demands of these engines, providing a seamless connection that enhances overall engine efficiency and reliability. The flexibility and durability of this hose assembly are key factors in maintaining the performance and longevity of these engines.

Role of Part 3100073 Flexible Hose Assembly in Engine Systems

The Part 3100073 Flexible Hose Assembly is integral to the efficient operation of various engine systems, facilitating the seamless transfer of fluids and gases under varying pressures and temperatures.

In the 24V Sentinel Install Kit, this hose assembly ensures that the high-pressure oil lines remain intact and flexible, accommodating the engine’s movements without compromising the integrity of the oil supply to critical components.

When integrated with the Sentinel Valve Kit, the flexible hose assembly allows for dynamic adjustments and movements, ensuring that the valve operations remain smooth and unhindered, which is essential for maintaining optimal engine performance.

For the Centinel Make-up QSX Kit, the hose assembly plays a significant role in delivering consistent oil flow to the make-up system, ensuring that the engine’s lubrication needs are met under all operating conditions.

In the ISX Burn-Only Valve/Mounting Kit, the flexible hose assembly provides the necessary flexibility to accommodate thermal expansion and contraction, ensuring that the valve system operates efficiently without undue stress on the connections.

The Oil Control Valve system benefits from the flexible hose assembly by ensuring that oil distribution is precise and reliable, which is vital for maintaining engine efficiency and longevity.

Lastly, in the Oil Replenishing System, the hose assembly ensures that the replenishing process is smooth and uninterrupted, helping to maintain the engine’s lubrication system in top condition.

Overall, the Part 3100073 Flexible Hose Assembly is a key component in ensuring the reliability and efficiency of these engine systems.

Conclusion

The 3100073 Flexible Hose Assembly by Cummins is a critical component in the fluid transfer systems of commercial trucks and various engine models. Its design and features contribute to the efficient operation and longevity of these systems. Proper installation, maintenance, and safety precautions are essential to ensure the optimal performance and reliability of this Cummins part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Reif, Konrad, ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual for QSF3.8 CM2350 F125. Bulletin Number 5411495.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.