This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

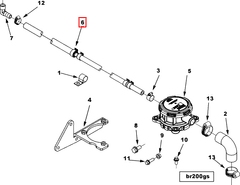

The Cummins 3103863 Flexible Hose is a component designed for use in commercial truck systems. It serves a specific function within these systems, facilitating the transfer of fluids or gases between different parts of the vehicle. Cummins, the manufacturer, is well-regarded in the industry for its commitment to quality and innovation in commercial vehicle components 2.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in various automotive and industrial applications to connect different system components, allowing for movement and vibration without compromising the integrity of the connection. These hoses are typically made from materials such as rubber, plastic, or metal, each offering distinct properties like flexibility, durability, and resistance to specific chemicals or temperatures 1.

Purpose of the Cummins 3103863 Flexible Hose

This Cummins part is engineered to play a role in the operation of commercial trucks by connecting specific systems and transporting fluids or gases. Its design allows it to accommodate the dynamic movements and vibrations inherent in truck operations, ensuring a reliable connection between components.

Key Features

The 3103863 incorporates several design elements and construction materials that enhance its performance and durability. These may include reinforced layers for added strength, specialized coatings for resistance to chemicals or weathering, and precise engineering to ensure compatibility with the systems it serves.

Benefits

Using this part in commercial truck applications offers several advantages. These include improved flexibility to accommodate vehicle movements, resistance to vibration which can extend the lifespan of the hose, enhanced durability under varying conditions, and ease of installation which can reduce downtime during maintenance procedures.

Installation Considerations

When installing the 3103863, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes ensuring proper alignment with connected components, using appropriate securing methods to maintain a stable connection, and verifying compatibility with existing systems to prevent issues such as leaks or reduced efficiency.

Troubleshooting Common Issues

Common problems with flexible hoses, such as leaks, kinks, or degradation, can often be addressed through systematic troubleshooting. This may involve inspecting the hose for visible damage, checking connections for proper alignment and securement, and assessing the condition of the hose material for signs of wear or chemical exposure.

Maintenance Tips

Regular maintenance practices are key to ensuring the longevity and reliable performance of the 3103863. This includes routine inspections for signs of wear or damage, cleaning the hose and its connections to remove contaminants, and following manufacturer guidelines for replacement to prevent unexpected failures.

Safety Considerations

When working with flexible hoses, it is important to adhere to safety practices to protect both the technician and the vehicle. This includes proper handling of the hose to avoid damage, installation in accordance with manufacturer guidelines to ensure safe operation, and awareness of potential hazards such as fluid leaks or hose failure which could pose risks to vehicle operation or personal safety.

Environmental Impact

The use and disposal of flexible hoses present environmental considerations. Materials used in hose construction may vary in recyclability, and proper disposal methods are important to minimize environmental harm. Manufacturers and users alike should consider these factors in the selection, use, and disposal of flexible hoses.

About Cummins

Cummins Inc. has a long-standing reputation in the commercial vehicle industry for its innovative products and commitment to quality. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins continues to play a significant role in the advancement of commercial vehicle technology and efficiency 2.

Compatibility with Engine Models

The 3103863 is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and reliability. This hose is engineered to provide flexibility and durability, making it suitable for use in demanding environments. Below is a detailed overview of the engine models with which this hose is compatible.

ISM CM570

The ISM CM570 engine is a robust and efficient power unit, and the 3103863 is specifically engineered to integrate smoothly with this model. Its design allows for easy installation and ensures that the hose can withstand the operational stresses of the engine.

ISZ13 CM2150 Z105 and QSZ13 CM2150 Z101

Both the ISZ13 CM2150 Z105 and QSZ13 CM2150 Z101 engines benefit from the use of the 3103863. This hose is compatible with these models due to its flexibility and durability, which are critical for maintaining the integrity of the engine’s fluid systems. The hose’s design ensures a secure fit and reliable performance in these high-performance engines.

QSZ13 CM2150 Z102

The QSZ13 CM2150 Z102 engine is another model that is well-suited for the 3103863. This hose is engineered to provide a precise fit, ensuring that it can handle the operational demands of the engine without compromising on performance or reliability.

Z13 Z108G

The Z13 Z108G engine also benefits from the use of the 3103863. This hose is designed to integrate seamlessly with this engine model, providing the necessary flexibility and durability to ensure optimal performance and longevity.

By ensuring compatibility with these engine models, the 3103863 from Cummins offers a reliable and efficient solution for maintaining the integrity of the engine’s fluid systems.

Role of 3103863 in Engine Systems

In the context of engine systems, the 3103863 is integral to the functionality and efficiency of several components.

Breather System Integration

The flexible hose is employed within the breather system to facilitate the release of pressure build-up within the engine’s crankcase. This system is designed to allow gases and vapors to escape, preventing excessive pressure that could lead to leaks or damage. The hose’s flexibility ensures a secure fit around various engine contours, maintaining a sealed environment while accommodating movement and vibrations inherent in engine operation.

Crankcase Ventilation

In the crankcase ventilation system, the flexible hose plays a significant role by connecting the crankcase to the intake manifold or another suitable outlet. This connection allows for the safe venting of gases produced during combustion that have entered the crankcase. The hose’s design ensures that these gases are directed back into the intake system, where they can be re-burned, thus reducing emissions and improving overall engine efficiency.

System Reliability and Maintenance

The use of a flexible hose in these systems enhances reliability by reducing the risk of cracks or breaks that rigid hoses might experience under the stress of engine vibrations and thermal expansion. This durability is essential for maintaining the integrity of the breather and crankcase ventilation systems, ensuring they operate effectively throughout the engine’s lifespan.

Conclusion

In summary, the 3103863 Flexible Hose is a key component in managing pressure and venting gases within engine systems, contributing to the overall performance and longevity of the engine. Its compatibility with various engine models, coupled with its design features and benefits, makes it a valuable asset in commercial truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.