The Cummins 3335583 Flexible Hose is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by facilitating the transfer of fluids or gases between different parts of the truck’s systems. Understanding its function and importance can contribute to better maintenance practices and overall system reliability.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in various automotive systems to transfer fluids or gases. They are designed to provide a flexible connection between rigid components, accommodating movement and vibration that occur during operation. In automotive applications, flexible hoses are commonly used in fuel, coolant, brake, and hydraulic systems, among others. Their ability to bend and flex helps to prevent stress on connected components and reduces the risk of leaks or failures due to vibration 1.

Purpose of the Cummins 3335583 Flexible Hose

The Cummins 3335583 Flexible Hose is specifically engineered to connect various systems within a truck, allowing for the transfer of fluids or gases. It plays a role in ensuring that these systems operate efficiently by providing a reliable and flexible connection point. The hose is typically used in applications where rigid pipes cannot accommodate the necessary movement or where the design requires a more adaptable solution 2.

Key Features

The Cummins 3335583 Flexible Hose is characterized by several key features that enhance its performance and longevity. These include its material composition, which is designed to withstand the pressures and temperatures of the fluids or gases it transfers. The hose exhibits high flexibility, allowing it to bend and twist without compromising its integrity. Durability is another important feature, ensuring that the hose can withstand the rigors of daily use in a commercial truck environment. Additionally, the design of the hose may include reinforced ends or special fittings to ensure a secure connection and prevent leaks 3.

Benefits

The use of the Cummins 3335583 Flexible Hose offers several advantages. It contributes to improved system reliability by providing a flexible and durable connection between components. This reduces the risk of leaks, which can occur with rigid connections subjected to vibration and movement. The flexibility of the hose also allows for more efficient routing within the truck’s system, potentially enhancing operational efficiency. Furthermore, the durable construction of the hose means it can withstand the demands of commercial use, leading to a longer service life 4.

Installation Considerations

Proper installation of the Cummins 3335583 Flexible Hose is important to ensure its effective operation and longevity. Installation techniques should include careful alignment of the hose with the components it connects to, ensuring that there is no twisting or kinking that could impede flow or cause damage. Securing methods, such as clamps, should be used to hold the hose in place and prevent disconnection. It is also important to ensure that the hose fits correctly within the truck’s system, with no excessive length that could lead to unnecessary stress or movement.

Troubleshooting Common Issues

Common problems associated with flexible hoses include leaks, kinks, or degradation over time. To address these issues, regular inspections should be conducted to identify any signs of wear or damage. If a leak is detected, the source should be located and repaired or replaced as necessary. Kinks can often be resolved by repositioning the hose to allow for a more natural bend. Degradation may require replacement of the hose to ensure continued reliable operation.

Maintenance Tips

Regular maintenance practices can help prolong the life of the Cummins 3335583 Flexible Hose. Inspection intervals should be established to check for signs of wear, leaks, or damage. Cleaning procedures may be necessary to remove any buildup that could affect the hose’s performance. When considering replacement, factors such as the age of the hose, the presence of visible damage, or a history of leaks should be taken into account.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications.

Flexible Hose Part 3335583 in ISM CM570 and QSM11 CM570 Engines

The Flexible Hose part 3335583, manufactured by Cummins, is a critical component in the ISM CM570 and QSM11 CM570 engines. This hose is designed to provide flexibility and durability, ensuring efficient operation and longevity of the engines.

In the ISM CM570 engine, the flexible hose is integral to the cooling system, allowing for the movement and flexibility required as the engine operates under various conditions. Its placement and design ensure that it can withstand the thermal and mechanical stresses inherent in engine operation.

Similarly, in the QSM11 CM570 engine, the flexible hose part 3335583 plays a vital role in the engine’s hydraulic or cooling systems. Its design accommodates the necessary flexibility to connect various components while maintaining a secure and leak-proof seal. This ensures that the engine operates smoothly and efficiently, with minimal risk of damage from movement or thermal expansion.

Both engines benefit from the use of this part, as it helps to maintain the integrity of the system it is part of, contributing to the overall performance and reliability of the engine.

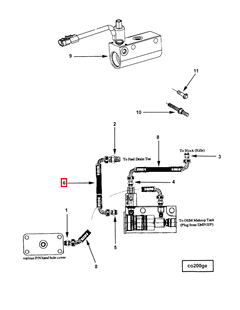

Role of Part 3335583 Flexible Hose in Engine Systems

The part 3335583 Flexible Hose is an integral component in various engine systems, facilitating the smooth operation and efficiency of several key elements.

In the kit, the flexible hose allows for the transfer of fluids between different components, ensuring that each part receives the necessary lubrication and cooling. This is particularly important in high-stress environments where rigid hoses might fail due to vibrations or thermal expansion.

When integrated with the ISM Valve & Mounting, the flexible hose provides a reliable connection that can accommodate minor misalignments and movements. This flexibility reduces the risk of leaks and ensures consistent performance of the ISM Valve, which is responsible for managing intake air temperature and pressure.

In systems involving the Oil Control Valve, the flexible hose plays a significant role in maintaining the integrity of the oil flow. It allows for dynamic adjustments in oil pressure and volume, which are essential for optimal engine performance and longevity. The hose’s flexibility ensures that oil can be efficiently distributed even under varying operational conditions.

Within the broader System, the flexible hose contributes to the overall reliability and durability. It acts as a buffer against the mechanical stresses that can occur during engine operation, thereby prolonging the lifespan of connected components.

Lastly, in Oil Replenishing setups, the flexible hose ensures that the oil supply lines remain intact and functional. This is vital for maintaining the correct oil levels within the engine, which is essential for lubrication, cooling, and overall engine health.

Overall, the part 3335583 Flexible Hose enhances the functionality and reliability of these engine components by providing a durable, flexible connection that can withstand the rigors of engine operation.

Conclusion

The Cummins 3335583 Flexible Hose is a vital component in the operation of commercial trucks, particularly in the ISM CM570 and QSM11 CM570 engines. Its design and features ensure efficient fluid transfer, system reliability, and durability under demanding conditions. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize its performance and longevity.

-

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines, The MIT Press, 2010.

↩ -

John F Kershaw, SAE International’s Dictionary for Automotive Engineers, SAE International, 2023.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Konrad Reif, Diesel Engine Management Systems and Components, Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.