This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3353861 Flexible Hose is a component designed for use in commercial truck operations. It serves as a vital link in various systems within the truck, facilitating the transfer of fluids and contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive systems to connect different components while allowing for movement and vibration absorption. They are typically made from materials that offer flexibility, durability, and resistance to the fluids they transport. In automotive applications, flexible hoses play a role in connecting parts of the engine, cooling, and fuel systems, among others 1.

Purpose of the Cummins 3353861 Flexible Hose

The Cummins 3353861 Flexible Hose is specifically designed to connect various systems within a truck, transporting fluids such as coolant, fuel, or hydraulic fluid. It enables these systems to operate efficiently by providing a flexible connection that can accommodate the movement and vibrations inherent in truck operations 2.

Key Features

The Cummins 3353861 Flexible Hose is characterized by several key features that enhance its performance and longevity. These include a material composition that offers resistance to the specific fluids it transports, flexibility to accommodate movement, durability to withstand the rigors of truck operations, and design specifications that ensure a secure and reliable connection 3.

Benefits

The Cummins 3353861 Flexible Hose offers several advantages over rigid hoses. Its flexibility allows it to absorb vibrations, reducing the transmission of these vibrations to connected components. This can lead to improved system performance and longevity. Additionally, its design helps to prevent leaks, enhancing safety and reliability 4.

Installation Considerations

When installing the Cummins 3353861 Flexible Hose, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes ensuring proper alignment with connected components, using appropriate securing methods to maintain a tight connection, and verifying compatibility with the truck’s existing systems to prevent issues such as leaks or improper function.

Troubleshooting Common Issues

Common problems associated with flexible hoses include leaks, kinks, and degradation over time. To address these issues, regular inspections should be conducted to identify signs of wear or damage. If a leak is detected, the hose should be replaced to prevent fluid loss and potential system failure. Kinks can often be resolved by repositioning the hose, while degradation may necessitate replacement to maintain system integrity.

Maintenance Tips

To maintain the Cummins 3353861 Flexible Hose, regular inspection routines should be established. This involves checking for signs of wear, such as cracks, leaks, or softening of the material, and addressing these issues promptly. Additionally, understanding the expected lifespan of the hose and monitoring its condition can help determine when replacement is necessary to ensure continued safe and efficient operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation, offering a wide range of products designed to meet the needs of various industries, including commercial trucking. The company’s dedication to excellence is reflected in its products, which are engineered to deliver reliable performance and durability in demanding applications.

Role of Part 3353861 Flexible Hose in Engine Systems

In the realm of engine systems, the part 3353861 Flexible Hose serves as a vital conduit for the transfer of essential fluids, ensuring the seamless operation of various components. This hose is integral in maintaining the efficiency and reliability of the engine by facilitating the movement of fluids between different parts of the system.

Fluid Transfer in Filtration Systems

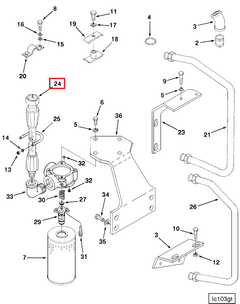

The flexible hose plays a significant role in filtration systems by connecting the filter to other components. It allows the passage of lubricating oil from the reservoir to the filter, where contaminants are removed. This clean oil is then circulated back into the engine, ensuring that all moving parts are adequately lubricated and protected from wear and tear.

Lubricating Oil Circulation

In the context of lubricating oil systems, the flexible hose is responsible for transporting oil from the sump or reservoir to various engine components that require lubrication. This includes critical parts such as bearings, pistons, and camshafts. The consistent flow of lubricating oil is essential for reducing friction and heat, thereby enhancing the engine’s performance and longevity.

Oil Transfer in Tube Systems

When it comes to tube oil transfer systems, the flexible hose acts as a flexible link between rigid tubing and other components. This is particularly important in applications where vibrations or movements are present, as the hose can absorb shocks and prevent damage to the more rigid parts of the system. The hose ensures a steady supply of oil to areas that need it, maintaining the engine’s operational integrity.

Integration with Other Components

Beyond its primary function of fluid transfer, the flexible hose also integrates with other engine components to create a cohesive system. For instance, it may connect to sensors that monitor oil pressure and temperature, providing vital data to the engine control unit. This integration allows for real-time adjustments and ensures that the engine operates within optimal parameters.

Conclusion

In summary, the Cummins 3353861 Flexible Hose is a fundamental element in engine systems, facilitating the efficient transfer of fluids and contributing to the overall performance and reliability of the engine. Its flexibility, durability, and integration capabilities make it an essential component in the maintenance and operation of commercial trucks.

-

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics (Springer Nature, 2023)

↩ -

John F Kershaw, SAE International’s Dictionary for Automotive Engineers (SAE International, 2023)

↩ -

Qianfan Xin, Diesel Engine System Design (Woodhead Publishing, 2011)

↩ -

Forbes Aird, Bosch Fuel Injection Systems (HP Books, 2001)

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.