This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

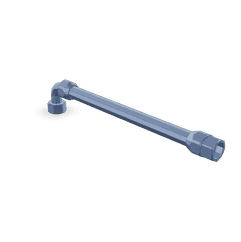

The Cummins 3401212 Flexible Hose is a component designed for use in commercial trucks, manufactured by Cummins Inc. This hose is integral to the efficient operation of truck systems, facilitating the transfer of fluids between various components. Flexible hoses are vital in the automotive industry due to their ability to accommodate movement and vibration, which are common in vehicle operations 1.

Basic Concepts of Flexible Hoses

Flexible hoses are conduits that allow for the transfer of fluids, gases, or even electrical signals within vehicles. They are designed to withstand the dynamic environment of a moving vehicle, accommodating shifts and vibrations without compromising the integrity of the connection. These hoses are typically made from materials such as rubber, thermoplastic, or metal, each offering distinct properties like flexibility, durability, and resistance to various environmental factors 2.

Purpose of the 3401212 Flexible Hose in Truck Operations

The Cummins 3401212 Flexible Hose serves a specific function in truck operations by connecting various systems and enabling the transport of fluids. It is engineered to link components that may move relative to each other, ensuring a consistent and secure flow of fluids despite the operational stresses encountered in truck systems 3.

Key Features of the 3401212 Flexible Hose

The Cummins 3401212 Flexible Hose is characterized by several key features that enhance its performance and durability. Its design incorporates materials that offer resistance to wear and environmental factors. The construction includes layers that provide strength and flexibility, allowing it to withstand the pressures and movements inherent in truck operations. Unique attributes may include reinforced sections for added durability in high-stress areas 4.

Benefits of Using the 3401212 Flexible Hose

Incorporating the Cummins 3401212 Flexible Hose into truck systems offers several advantages. Its flexibility allows it to accommodate the movement and vibration typical in truck operations, reducing the risk of disconnection or damage. The hose’s resistance to wear and tear contributes to its longevity, while its design may include features that enhance safety, such as burst-resistant layers 5.

Installation Considerations

When installing the Cummins 3401212 Flexible Hose, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes using the necessary tools for a secure fit, following steps for correct installation, and avoiding common pitfalls such as over-tightening or improper alignment. Careful installation helps maintain the integrity of the hose and the systems it connects 6.

Troubleshooting Common Issues

Common problems associated with flexible hoses, such as leaks or blockages, can often be identified through regular inspections. Troubleshooting steps may include checking for signs of wear, ensuring proper connections, and addressing any issues promptly to prevent further damage. Regular maintenance and inspections are key to identifying and resolving issues before they lead to more significant problems 7.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3401212 Flexible Hose, regular maintenance is recommended. This includes cleaning the hose to remove any buildup that could affect its function, conducting routine inspections for signs of wear or damage, and considering replacement when necessary to maintain system integrity and safety 8.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has built a reputation for reliability and performance. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the automotive components market 9.

Role of Part 3401212 Flexible Hose in Engine Systems

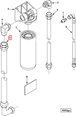

The part 3401212 Flexible Hose is an essential component in the efficient operation of various engine systems. Its primary function is to facilitate the smooth transfer of fluids between different parts of the engine, ensuring that the system operates without interruptions.

In the context of the Full Flow Oil System, the Flexible Hose connects the oil filter to the engine block or oil pump. This connection allows for the continuous circulation of oil, which is vital for lubricating moving parts, reducing friction, and dissipating heat. The flexibility of the hose accommodates the vibrations and movements inherent in engine operation, preventing potential leaks and maintaining system integrity.

Additionally, the hose plays a significant role in the Oil Filter System. By providing a secure and flexible connection, it ensures that the oil filter receives a steady flow of oil. This consistent flow is necessary for the filter to effectively remove contaminants and maintain the cleanliness of the oil, which in turn protects the engine’s internal components from wear and damage.

Overall, the 3401212 Flexible Hose is integral to maintaining the reliability and performance of engine systems by ensuring uninterrupted fluid transfer and accommodating the dynamic environment within the engine 10.

Conclusion

The Cummins 3401212 Flexible Hose is a critical component in the operation of commercial truck systems, offering flexibility, durability, and resistance to environmental factors. Its role in facilitating the transfer of fluids between various engine components ensures the smooth and efficient operation of truck systems. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4388628.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4388628.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4388628.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4388628.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4388628.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4388628.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.