3682896

Flexible Hose

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Overview of Cummins Part #3682896: A Flexible Hose in Commercial Truck Engines

Introduction to Flexible Hoses in Commercial Trucks

Flexible hoses are indispensable in commercial truck engines, enabling the transfer of fluids and gases while accommodating the dynamic movements of the engine and chassis. These hoses are engineered to endure high temperatures, pressures, and vibrations, ensuring dependable operation and durability 1.

The Role and Function of Cummins Part #3682896

The Cummins Part #3682896 Flexible Hose is meticulously designed to meet the stringent demands of commercial truck engines. This hose is commonly used to connect various fluid systems, including oil, coolant, and fuel lines, to the engine and other vital components. Its flexibility ensures smooth operation even when the engine and chassis move, minimizing the risk of leaks and damage 2.

How Cummins Part #3682896 Works

The Cummins Part #3682896 Flexible Hose is crafted from premium materials that offer exceptional durability and resistance to wear and tear. The inner lining is engineered to prevent corrosion and blockages, while the outer layer provides robust protection against abrasion and environmental factors. The hose’s design allows it to expand and contract, accommodating the thermal expansion and contraction of the fluids it transports 3.

Importance in Truck Operations

The Flexible Hose is pivotal for the efficient operation of commercial trucks. By ensuring a secure and flexible connection between various systems, it helps maintain optimal engine performance, prevent overheating, and reduce the risk of leaks. This contributes significantly to the overall reliability and safety of the vehicle 1.

Troubleshooting and Maintenance Tips

Regular inspection and maintenance of the Flexible Hose are vital to ensure its longevity and performance. Here are some essential troubleshooting and maintenance tips:

-

Visual Inspection: Conduct regular checks for signs of wear, such as cracks, bulges, or leaks. Inspect the connections for tightness and any signs of corrosion.

-

Pressure Testing: Perform pressure tests to ensure the hose can withstand the required pressures without leaking. This is particularly crucial for high-pressure systems.

-

Cleaning: Keep the hose and its connections clean to prevent blockages and corrosion. Use appropriate cleaning agents and tools to avoid damaging the hose.

-

Replacement: Replace the hose if any damage is detected. Using genuine Cummins parts ensures compatibility and maintains the integrity of the system 2.

Cummins: A Leader in Engine Manufacturing

Cummins is a distinguished manufacturer of engines and related components for commercial trucks. With a steadfast commitment to quality and innovation, Cummins products are designed to deliver exceptional performance and reliability. The company’s extensive experience and expertise in the industry make it a trusted source for heavy-duty truck parts 3.

Cummins Flexible Hose Part 3682896

The Cummins Flexible Hose part number 3682896 is designed to integrate seamlessly with a variety of Cummins engine models, ensuring reliable and efficient performance. This hose is engineered to withstand the rigors of heavy-duty applications, providing a flexible connection that accommodates movement and reduces stress on the engine components.

ISX CM870 Engine

In the ISX CM870 engine, the Flexible Hose part 3682896 plays a crucial role in maintaining the integrity of the engine’s cooling system. It connects various coolant lines, allowing for flexibility as the engine operates under different conditions. This hose is critical in preventing leaks and ensuring that the engine maintains optimal operating temperatures.

Grouping of Engines

The Cummins Flexible Hose part 3682896 is also compatible with other Cummins engines within the same family as the ISX CM870. These engines share similar design principles and operational requirements, making the hose a versatile component across multiple models. The flexibility and durability of this part make it an essential component in these engines, facilitating smooth operation and longevity.

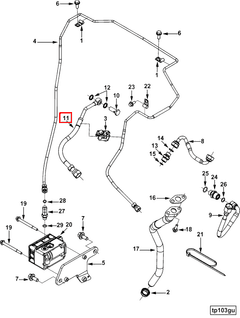

Role of Part 3682896 Flexible Hose in Plumbing and Turbocharger Systems

Plumbing Systems

In plumbing systems, the part 3682896 Flexible Hose is utilized to connect various components that facilitate the flow of fluids. This hose is particularly beneficial in scenarios where rigid piping cannot be used due to space constraints or the need for flexibility. It is commonly employed to link water supply lines to appliances such as washing machines, dishwashers, and refrigerators with built-in ice makers. The flexibility of the hose allows for easy installation and maintenance, accommodating the movement and vibrations that occur during the operation of these appliances. Additionally, in residential and commercial buildings, this hose is used to connect water heaters to the main supply lines, ensuring a reliable and leak-free connection.

Turbocharger Systems

In turbocharger systems, the part 3682896 Flexible Hose plays a significant role in managing the high-pressure air flow from the turbocharger to the engine’s intake manifold. This hose is designed to withstand the extreme temperatures and pressures generated by the turbocharger, ensuring a durable and efficient connection. It is often used to connect the turbocharger outlet to the intercooler, allowing for the cooling of compressed air before it enters the engine. This enhances engine performance by ensuring that the air entering the combustion chamber is at an optimal temperature. Furthermore, the flexibility of the hose accommodates the engine’s movement and vibrations, reducing the risk of damage to the connections and improving the overall reliability of the turbocharger system.

Conclusion

Understanding the function and importance of the Cummins Part #3682896 Flexible Hose is essential for engineers, mechanics, truck drivers, and fleet operators. Proper maintenance and troubleshooting can significantly enhance the performance and lifespan of this critical component, ensuring the smooth operation of commercial trucks.

-

Gilles, T. (2020). Automotive Service Inspection Maintenance Repair. Cengage Learning.

↩ ↩ -

Hilgers, M. (2022). Commercial Vehicle Technology: The Drivers Cab. Springer Vieweg.

↩ ↩ -

Cummins® Electronic Throttle and Shift (ETS) and Cummins® Inboard Joystick Marine Controls MC101 Operation and Maintenance Manual, Bulletin Number 4358379.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.