This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

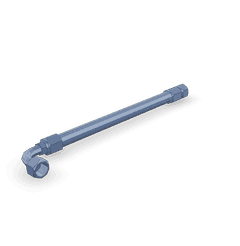

The Cummins 3914500 Flexible Hose is a component designed for use in commercial trucks. Manufactured by Cummins Inc., a company renowned for its robust and reliable engine and powertrain solutions, this part plays a role in facilitating the transfer of fluids within the truck’s systems, ensuring efficient operation and maintenance of various engine components 1.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive systems to connect different components that require fluid transfer. They are designed to accommodate movement and vibration, which are common in vehicle operations. These hoses operate by providing a conduit for fluids such as coolant, fuel, or hydraulic fluid, allowing them to flow between parts that may not be fixed in position relative to each other 1.

Purpose of the Cummins 3914500 Flexible Hose

The Cummins 3914500 Flexible Hose is specifically engineered to connect systems within a truck that require fluid transport. It facilitates the movement of fluids between components that experience relative motion, such as the engine and radiator in a cooling system. This hose ensures a secure and leak-free connection, contributing to the overall functionality and reliability of the truck’s systems.

Key Features

The Cummins 3914500 Flexible Hose is characterized by several features that enhance its performance and durability. It is constructed from materials that offer resistance to the specific fluids it transports, as well as to the environmental conditions it encounters. The design includes reinforced ends to ensure a secure fit with connecting components, and the hose itself is crafted to withstand pressure fluctuations and temperature variations typical in commercial truck operations.

Benefits

The use of the Cummins 3914500 Flexible Hose provides several advantages. Its flexibility allows it to accommodate the movement and vibration inherent in truck operations, reducing the risk of leaks and disconnections. The hose’s resistance to wear and tear contributes to its longevity, and its design enhances the efficiency of the truck’s systems by ensuring a consistent and reliable fluid flow.

Installation Considerations

When installing the Cummins 3914500 Flexible Hose, it is important to follow guidelines to ensure compatibility with other components and to use the necessary tools and procedures. Proper installation involves verifying that the hose fits securely with the components it connects, using the appropriate clamps or fittings, and ensuring that there are no kinks or sharp bends in the hose that could impede fluid flow or cause premature wear.

Troubleshooting Common Issues

Flexible hoses, including the Cummins 3914500, may encounter issues such as leaks, cracks, or blockages. These problems can arise from wear and tear, improper installation, or exposure to extreme conditions. Identifying the cause of an issue is the first step in addressing it, whether it involves replacing the hose, repairing a connection, or adjusting the system to reduce stress on the hose.

Maintenance Tips

Regular maintenance of the Cummins 3914500 Flexible Hose is key to ensuring its longevity and reliable performance. This includes routine inspections for signs of wear, such as cracks or leaks, and checking the connections for tightness. Replacement guidelines should be followed to ensure that the hose is changed before it fails, contributing to the overall efficiency and safety of the truck’s systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Role of Part 3914500 Flexible Hose in Engine Systems

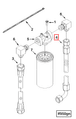

In the context of engine systems, the Cummins 3914500 Flexible Hose serves as a vital connector that facilitates the smooth operation of various components. Specifically, it plays a significant role in the integration of the filter and the full-flow oil system.

Integration with the Filter

The Flexible Hose is instrumental in linking the engine’s filtration system. It ensures that contaminants are effectively removed from the oil before it circulates through the engine. This connection is essential for maintaining the integrity of the oil, which in turn protects the engine from wear and damage. The hose’s flexibility allows it to accommodate the vibrations and movements inherent in engine operation, ensuring a secure and durable connection 2.

Connection to the Full-Flow Oil System

In the full-flow oil system, the Flexible Hose acts as a conduit for the oil as it travels from the oil pump to the various engine components that require lubrication. This system is designed to handle the majority of the oil flow, ensuring that all moving parts are adequately lubricated. The hose’s role here is to provide a reliable pathway for the oil, minimizing the risk of leaks and ensuring consistent oil pressure throughout the system 2.

Overall Functionality

By seamlessly integrating with both the filter and the full-flow oil system, the Flexible Hose enhances the overall efficiency and reliability of the engine. Its design allows for easy installation and maintenance, making it a practical choice for both engineers and mechanics. The hose’s ability to flex and move with the engine components ensures that it can withstand the rigors of engine operation, contributing to the longevity and performance of the engine system.

Conclusion

The Cummins 3914500 Flexible Hose is a critical component in the efficient operation of commercial trucks. Its design and features ensure reliable fluid transfer, accommodating the dynamic conditions of engine operation. Regular maintenance and proper installation are essential to maximize its performance and longevity, contributing to the overall efficiency and safety of the truck’s systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.