This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

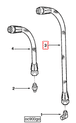

The Cummins 3916046 Flexible Hose is a critical component in commercial truck systems, designed to facilitate the transfer of various fluids between different parts of the truck’s system. This part ensures the operational efficiency and safety of the vehicle by providing a reliable conduit for fluid transfer 1.

Basic Concepts of Flexible Hoses

Flexible hoses are constructed from materials that allow them to bend and flex without breaking, making them ideal for automotive and industrial applications where movement or vibration is expected 2. They are used to transport fluids such as fuel, coolant, and hydraulic fluid, offering a more durable solution compared to rigid pipes in dynamic environments.

Purpose of the Cummins 3916046 Flexible Hose

The Cummins 3916046 Flexible Hose is engineered to connect various systems within a commercial truck, enabling the transfer of fluids such as coolant or hydraulic fluid. It ensures that these fluids reach their intended destinations, supporting the overall functionality and performance of the vehicle 3.

Key Features

This Cummins part is constructed from durable materials that resist wear and tear and the chemicals present in the transported fluids. It features reinforced ends for secure connections and may include protective coatings or layers to enhance performance and longevity 4.

Benefits

Using the Cummins 3916046 Flexible Hose offers several advantages. Its flexibility accommodates the movements and vibrations typical in a commercial truck environment, reducing the risk of leaks or damage. The hose’s resistance to wear and tear, along with its design features, contributes to safer and more efficient fluid transfer. Additionally, its durability helps maintain the truck’s operational efficiency over time 5.

Installation Considerations

When installing the Cummins 3916046 Flexible Hose, it is important to ensure compatibility with the truck’s existing components. Proper installation involves using the correct tools and following procedures that secure the hose in place without damaging it or the connections. Attention to detail during installation can prevent future issues and ensure the hose functions as intended 6.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 3916046 Flexible Hose, regular maintenance is recommended. This includes checking for signs of wear or damage, ensuring connections remain secure, and replacing the hose if it shows signs of degradation. Common issues may include leaks or reduced flexibility, which can often be addressed through proper maintenance practices 7.

Safety Precautions

When working with the Cummins 3916046 Flexible Hose, observing safety measures is crucial. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and cooled down before beginning work, and following proper handling and installation procedures to avoid injury or damage to the vehicle 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles 9.

Role of Part 3916046 Flexible Hose in Engine Systems

The Cummins 3916046 Flexible Hose is an essential component in various engine systems, facilitating the transfer of fluids between different parts of the system. Its application in the following components highlights its versatility and importance:

Cooler Systems

In cooler systems, the flexible hose connects the engine to the cooler, allowing coolant to circulate. This circulation helps maintain optimal engine temperature by dissipating excess heat. The flexibility of the hose accommodates the movement and vibrations inherent in engine operation, ensuring a secure and durable connection 10.

Marine Gear Oil Systems

For marine gear oil systems, the flexible hose plays a significant role in transferring oil between the gearbox and the sump. This ensures that the gearbox remains adequately lubricated, reducing friction and wear on moving parts. The hose’s flexibility is particularly beneficial in marine environments, where equipment is subject to constant motion and harsh conditions 11.

Filter Systems

In filter systems, the flexible hose is used to connect the filter housing to the engine or other components. This connection allows for the smooth flow of oil or other fluids to the filter, where contaminants are removed. The hose’s flexibility ensures that the connection remains intact despite the vibrations and movements typical in engine compartments 12.

Full Flow Oil Systems

Within full flow oil systems, the flexible hose is employed to route oil from the pump to various engine components, ensuring they receive a consistent supply of lubricant. This consistent flow is vital for the engine’s performance and longevity, as it prevents metal-to-metal contact and reduces wear. The hose’s ability to flex and move with the engine components enhances the system’s reliability and efficiency 13.

Conclusion

The Cummins 3916046 Flexible Hose is a versatile and durable component essential for the efficient operation of commercial truck systems. Its design and features ensure reliable fluid transfer, accommodating the dynamic environments in which these vehicles operate. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩ -

Cummins Inc. Service Manual (5504273).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.