This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To Flexible Hoses In Commercial Trucks

Flexible hoses are integral components in commercial truck engines, facilitating the transfer of fluids and gases between various parts of the engine. These hoses are designed to withstand high pressures and temperatures, ensuring efficient and reliable operation 3. This article delves into the specifics of the Cummins 3916107 Flexible Hose, its role in truck engines, and best practices for maintenance and troubleshooting.

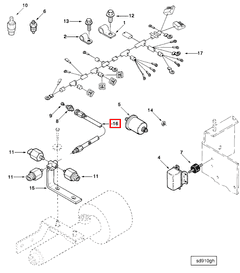

The Role Of The Cummins 3916107 Flexible Hose

The Cummins 3916107 Flexible Hose is a critical component in the engine’s operation, connecting different parts and ensuring the smooth flow of fluids and gases. This hose is engineered to handle the rigors of commercial truck use, providing durability and reliability under demanding conditions 1.

How The Cummins 3916107 Flexible Hose Works

The Cummins 3916107 Flexible Hose operates by connecting the engine’s turbocharger to the intake manifold. It allows for the efficient transfer of compressed air from the turbocharger to the engine, enhancing performance and fuel efficiency. The hose’s flexibility and strength enable it to withstand the constant vibrations and stresses of engine operation 2.

Importance Of The Cummins 3916107 Flexible Hose In Truck Engines

The Cummins 3916107 Flexible Hose plays a vital role in the overall performance and efficiency of a truck engine. By ensuring a steady flow of compressed air, it helps to maintain optimal engine operation, reduce wear and tear, and improve fuel economy. This hose is essential for maintaining the engine’s power output and longevity 3.

Troubleshooting The Cummins 3916107 Flexible Hose

Regular inspection and maintenance are crucial for the proper functioning of the Cummins 3916107 Flexible Hose. Common issues include leaks, cracks, and excessive wear. Addressing these issues promptly is essential to prevent further damage.

- Leaks: Inspect the hose for any visible signs of leaks. If a leak is detected, replace the hose immediately to avoid engine damage.

- Cracks: Check the hose for cracks or brittleness. A cracked hose can lead to a loss of pressure and reduced engine performance.

- Wear And Tear: Regularly inspect the hose for signs of wear and tear. Replace the hose if it shows any signs of degradation.

Maintenance Tips For The Cummins 3916107 Flexible Hose

Proper maintenance of the Cummins 3916107 Flexible Hose can extend its lifespan and ensure optimal engine performance. Here are some maintenance tips:

- Regular Inspections: Conduct regular visual inspections of the hose for any signs of damage or wear.

- Cleaning: Keep the hose clean and free from debris. Use a soft brush or cloth to remove any dirt or grime.

- Proper Installation: Ensure the hose is correctly installed according to the manufacturer’s specifications. Improper installation can lead to leaks and other issues.

Cummins: A Leader In Engine Technology

Cummins is a renowned manufacturer of engines and related components for commercial trucks. With a commitment to quality and innovation, Cummins provides reliable and high-performance parts that meet the demanding needs of the trucking industry. The Cummins 3916107 Flexible Hose is a testament to their dedication to excellence and durability.

Expert Insights On The Cummins 3916107 Flexible Hose

As an expert in commercial truck parts, it is essential to understand the critical role that the Cummins 3916107 Flexible Hose plays in engine operation. By following the maintenance and troubleshooting tips outlined in this article, engineers, mechanics, and fleet operators can ensure the longevity and efficiency of their truck engines. Cummins’ reputation for quality and reliability makes their parts a trusted choice for the industry.

Compatibility with Engine Models

The 3916107 Flexible Hose is compatible with the following Cummins engine models:

- 6B5.9

- 6C8.3

These engines are known for their robust performance and reliability, often used in heavy-duty applications. The hose’s design accommodates the unique requirements of these engines, ensuring a secure and leak-free connection.

Installation and Functionality

The installation of the 3916107 Flexible Hose is straightforward, designed to fit precisely with the engine’s specifications. This hose is typically used to connect various fluid systems within the engine, facilitating the movement of essential fluids such as coolant, fuel, and oil. Its flexibility allows for easy maneuvering around engine components, reducing the risk of damage and wear.

Importance in Engine Performance

The proper functioning of the 3916107 Flexible Hose is crucial for maintaining optimal engine performance. It helps in preventing leaks and ensuring that fluids are transported efficiently, which is vital for the engine’s cooling, lubrication, and fuel systems. This part’s design ensures that it can withstand the high pressures and temperatures typical in engine environments, contributing to the overall reliability and efficiency of the engine.

Role of Part 3916107 Flexible Hose in Engine Systems

The part 3916107 Flexible Hose is integral to the efficient operation of various engine systems. In heat exchangers, this hose facilitates the transfer of thermal energy between fluids, ensuring optimal engine temperature regulation. Its flexibility accommodates the dynamic movements and vibrations inherent in engine operation, maintaining a secure and leak-free connection.

In plumbing systems, the hose serves as a vital conduit for fluids, whether it be coolant, fuel, or lubricants. Its design allows for easy installation and maintenance, reducing the risk of system failures due to rigid connections.

For keel coolers, the flexible hose is essential in managing the cooling process of engine lubricants. By providing a durable yet adaptable link between the keel cooler and the engine, it ensures consistent cooling performance, which is key to prolonging engine life.

In switch applications, the hose may be used to route fluids to activation mechanisms, ensuring that switches operate under the correct conditions without the risk of fluid leakage or connection failure.

Lastly, in engine monitoring systems, the hose plays a role in transporting fluids to sensors and gauges. This ensures accurate readings and timely alerts for any deviations in engine performance, contributing to overall system reliability and safety.

Conclusion

The Cummins 3916107 Flexible Hose is a critical component in the operation of commercial truck engines. Its role in ensuring the efficient transfer of fluids and gases, coupled with its durability and reliability, makes it an essential part for maintaining optimal engine performance. Regular maintenance and prompt troubleshooting are key to extending the lifespan of this part and ensuring the longevity and efficiency of truck engines. Cummins’ commitment to quality and innovation underscores the trustworthiness of their products in the demanding environment of commercial trucking.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.