This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3917736 Flexible Hose is a component designed for use in commercial trucks. It serves as a vital link in various fluid transfer systems within these vehicles, ensuring efficient and safe operation. This hose is engineered to withstand the demanding conditions encountered in heavy-duty applications, providing reliable performance and longevity 1.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive and heavy-duty truck applications to connect different parts of a system that may move or vibrate relative to each other. They are designed to accommodate movement and reduce stress on connected components, which helps maintain system integrity and performance. Flexible hoses function by allowing the free flow of fluids while withstanding pressure and environmental factors 2.

Purpose of the Cummins 3917736 Flexible Hose

The Cummins 3917736 Flexible Hose plays a role in connecting various systems within a truck, facilitating the transfer of fluids such as coolant, fuel, or hydraulic fluid. Its design allows it to absorb vibrations and movements that occur during operation, which helps protect the connected systems from damage and ensures consistent fluid flow 3.

Key Features

The Cummins 3917736 Flexible Hose is characterized by several features that enhance its performance. It is constructed from materials that offer flexibility and durability, allowing it to bend and twist without compromising its structural integrity. The hose is designed to resist wear and tear, chemical exposure, and temperature fluctuations, ensuring reliable operation in various conditions.

Benefits

Using the Cummins 3917736 Flexible Hose provides several advantages. Its flexibility reduces the risk of kinking and stress on connected components, which can lead to system failures. The hose’s resistance to wear and tear contributes to its longevity, reducing the need for frequent replacements. Additionally, its design enhances safety and efficiency in fluid transfer, supporting the overall performance of the truck.

Installation Considerations

When installing the Cummins 3917736 Flexible Hose, it is important to follow guidelines to ensure proper fitting and securement. This includes using the correct fittings and methods to attach the hose to the system, ensuring there are no leaks or weak points. Compatibility with the truck’s system should be verified to prevent issues during operation.

Troubleshooting Common Issues

Common problems with flexible hoses include leaks, kinks, and degradation over time. To address these issues, regular inspections should be conducted to identify any signs of wear or damage. Leaks can often be repaired by replacing fittings or sections of the hose, while kinks may require rerouting or replacement. Degradation may necessitate a complete hose replacement to maintain system integrity.

Maintenance Tips

Maintaining the Cummins 3917736 Flexible Hose involves regular inspections to check for signs of wear, leaks, or damage. Cleaning the hose according to manufacturer recommendations can help prevent buildup that may affect performance. Replacement should be considered when the hose shows significant signs of wear or if it has been in service for an extended period, to ensure continued reliable operation.

Safety Precautions

When working with the Cummins 3917736 Flexible Hose, it is important to observe safety measures. This includes handling hazardous fluids with care, using appropriate personal protective equipment, and ensuring that the system is depressurized before making any adjustments or repairs. Adhering to these precautions helps protect individuals from injury and ensures the safe operation of the vehicle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, demonstrating a commitment to excellence and customer satisfaction.

Cummins Part 3917736: Flexible Hose Compatibility

The Cummins part 3917736, a Flexible Hose, is designed to integrate seamlessly with various engine models, ensuring optimal performance and durability. This part is engineered to fit within the engine systems of the 4B3.9 and 6B5.9 engines, providing a reliable connection between different components.

For the 4B3.9 engine, the Flexible Hose 3917736 is specifically tailored to handle the unique demands of this engine model. Its design accommodates the precise fit and operational requirements, ensuring smooth fluid transfer and minimizing the risk of leaks or damage.

Similarly, in the 6B5.9 engine, the Flexible Hose 3917736 is engineered to match the engine’s specifications. This ensures that the hose can withstand the operational stresses and pressures, providing a stable and efficient connection throughout the engine’s lifecycle.

Both engines benefit from the use of this flexible hose, as it allows for necessary adjustments and movements within the engine compartment, accommodating the dynamic nature of engine components during operation. The compatibility of this part with both the 4B3.9 and 6B5.9 engines underscores its versatility and reliability in maintaining engine integrity and performance.

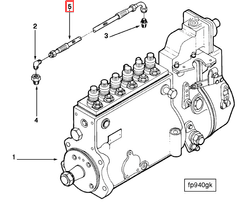

Role of Part 3917736 Flexible Hose in Engine Systems

The part 3917736 Flexible Hose is an integral component in the efficient operation of various engine systems. It serves as a vital conduit for the transfer of fluids, ensuring seamless connectivity between different parts of the engine.

In the context of the Base Fuel Pump, the flexible hose facilitates the movement of fuel from the tank to the pump. This ensures a consistent supply of fuel, which is essential for the pump’s operation. The hose’s flexibility accommodates the dynamic movements and vibrations inherent in engine operation, maintaining a secure and leak-free connection.

When integrated with the Fuel Pump Coupling, the hose plays a role in linking the fuel pump to other components within the fuel system. This connection is necessary for the efficient transfer of fuel and for maintaining system integrity under varying operational conditions.

In a Kit that includes multiple fuel system components, the flexible hose acts as a universal connector. It allows for easy assembly and disassembly, making maintenance and upgrades more straightforward. The hose’s design ensures compatibility with various components, enhancing the kit’s versatility.

For the Fuel Pump Conversion processes, the hose is often used to adapt existing fuel systems to new configurations. Its flexibility and durability make it ideal for custom installations, where precise fitting and reliable performance are paramount.

In conjunction with the Pump itself, the hose ensures that fuel is delivered efficiently from the pump to the engine’s combustion chambers. This is essential for maintaining optimal engine performance and fuel efficiency.

Lastly, in the broader Fuel system, the hose contributes to the overall reliability and efficiency of fuel delivery. It helps in reducing the risk of leaks and ensures that the fuel system operates smoothly under a range of conditions.

Conclusion

The Cummins 3917736 Flexible Hose is a critical component in the fluid transfer systems of commercial trucks. Its design and features ensure reliable performance, durability, and safety in various engine applications. Proper installation, maintenance, and adherence to safety precautions are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.