This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3920603 Flexible Hose is a component designed for use in commercial truck systems. It serves as a conduit for various fluids within the truck’s operational framework, ensuring efficient and reliable fluid transfer between different parts of the system.

Basic Concepts of Flexible Hoses

Flexible hoses are tubular components used in automotive and industrial applications to transport fluids such as coolant, fuel, oil, and air 1. They are designed to accommodate movement and vibration, which are common in vehicle operations, without compromising the integrity of the fluid pathway. Flexible hoses function by providing a durable yet adaptable connection between rigid components, allowing for necessary flexibility in dynamic environments.

Purpose of the Cummins 3920603 Flexible Hose

This part plays a specific role in the operation of commercial trucks. It connects various systems within the truck, facilitating the transport of fluids essential for the truck’s performance. This hose is integral to maintaining the fluidity of operations across different truck systems, ensuring that fluids are delivered where needed without leakage or disruption.

Key Features

This Cummins part is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to wear, corrosion, and the extreme conditions often encountered in commercial truck environments 2. Its design includes reinforced layers to withstand high pressure and temperature variations, ensuring reliable operation over time. Additionally, the hose features smooth inner and outer surfaces to minimize friction and maximize flow efficiency.

Benefits

The 3920603 Flexible Hose offers several advantages. Its flexibility allows it to adapt to the movements and vibrations inherent in truck operations, reducing the risk of damage or disconnection. The hose’s resistance to wear and tear ensures longevity, minimizing the need for frequent replacements. Furthermore, its design enhances safety and efficiency in fluid transfer, contributing to the overall reliability of the truck’s systems.

Installation Considerations

When installing this part, it is important to follow guidelines and best practices to ensure proper fit and function. Necessary tools include wrenches for securing connections and possibly a hose cutter for precise length adjustments. The installation process involves carefully routing the hose to avoid sharp edges or excessive bending, securing it firmly at both ends, and checking for proper alignment and tension. Common pitfalls to avoid include over-tightening connections, which can damage the hose, and insufficient routing, which may lead to abrasion or kinking.

Troubleshooting Common Issues

Flexible hoses, including the 3920603, may encounter issues such as leaks or degradation over time. Identifying the source of a leak involves inspecting the hose for visible damage, checking connection points for proper sealing, and ensuring there are no obstructions or sharp edges causing abrasion. Degradation can be assessed by looking for signs of cracking, softening, or discoloration. Addressing these issues may involve repairing or replacing the affected section of the hose, ensuring all connections are secure, and inspecting the surrounding area for potential causes of damage.

Maintenance Tips

Regular maintenance of the 3920603 Flexible Hose is key to ensuring its longevity and reliable performance. This includes periodic inspections for signs of wear, damage, or leaks, and cleaning the hose and its connections to remove any buildup that could impede fluid flow or cause corrosion. Care procedures should also involve checking the hose’s routing to ensure it is not subjected to unnecessary stress or abrasion. Following manufacturer recommendations for inspection schedules and maintenance practices will help maintain the hose’s condition and functionality.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and durability of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Engine Compatibility with Part 3920603 Flexible Hose

This part is designed to fit a variety of Cummins engines, ensuring a reliable connection between different components within the engine system. This part is engineered to provide flexibility and durability, accommodating the movement and vibrations inherent in engine operation.

Compatible Engines

-

4B3.9 and QSB3.9 30 CM550: These engines, part of the Cummins B and QSB series, benefit from the 3920603 Flexible Hose. This hose is particularly suited to the needs of these engines, providing a seamless connection that can endure the operational stresses of these models.

-

6B5.9 and QSB5.9 30 CM550: These larger engines also integrate the 3920603 Flexible Hose effectively. Given the higher power output and more complex systems in these engines, the flexibility and strength of this hose are crucial for maintaining performance and reliability.

-

6C8.3 and C8.3 G: The 3920603 Flexible Hose is also compatible with the 6C8.3 and C8.3 G engines. These engines, known for their robust performance, require a hose that can handle significant pressure and movement, which this part provides.

-

B4.5 and C GAS PLUS CM556: The 3920603 Flexible Hose is designed to fit these engines as well. Its flexibility and durability make it an ideal choice for the specific demands of these models, ensuring a secure and efficient connection.

This part is a critical component in the engine’s system, ensuring that connections remain intact and efficient under various operational conditions.

Role of Part 3920603 Flexible Hose in Engine Systems

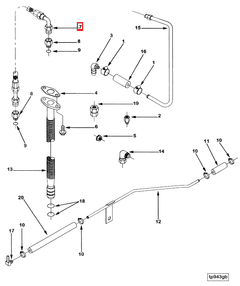

This part is an essential component in various engine systems, facilitating the transfer of fluids and gases under dynamic conditions. Its application spans across several critical areas, including plumbing and turbocharger systems.

Plumbing Systems

In plumbing systems, the Flexible Hose ensures a reliable connection between different components, accommodating the natural expansion and contraction of pipes due to thermal changes. This flexibility prevents stress on the connections, reducing the risk of leaks and system failures. The hose’s durable construction allows it to withstand high pressures and varying temperatures, making it suitable for both hot and cold fluid transfers.

Turbocharger Systems

Within turbocharger systems, the Flexible Hose plays a significant role in managing the flow of turbocharger oil and gases. It connects the turbocharger to the engine’s oil supply, ensuring a consistent and uninterrupted flow of lubricant to the turbocharger bearings. This lubrication is vital for the turbocharger’s performance and longevity, as it reduces friction and wear on moving parts.

Additionally, the Flexible Hose is used in turbocharger plumbing to handle the high-pressure exhaust gases that drive the turbine. Its flexibility accommodates the vibrations and movements inherent in turbocharger operation, maintaining a secure and leak-free connection. This ensures efficient turbocharger performance and contributes to the overall reliability of the engine system.

Conclusion

The Cummins 3920603 Flexible Hose is a vital component in commercial truck systems, designed to ensure efficient and reliable fluid transfer. Its flexibility, durability, and compatibility with various Cummins engines make it an essential part of maintaining the performance and reliability of commercial vehicles. Regular maintenance and proper installation are key to maximizing the lifespan and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.