This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

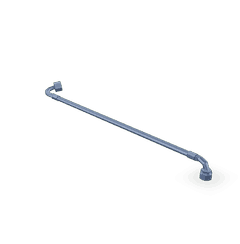

The Cummins 3930840 Flexible Hose is a component designed for use in commercial truck systems. Its purpose is to facilitate the transfer of fluids between various parts of the truck’s system, accommodating movement and vibration that rigid hoses cannot. This part plays a role in maintaining the efficiency and reliability of the truck’s operations by ensuring a secure and flexible connection between components 1.

Basic Concepts of Flexible Hoses

Flexible hoses are tubes made from materials that allow them to bend and flex without breaking. They are commonly used in automotive and industrial applications to connect systems that require movement or vibration isolation. Flexible hoses function by providing a pathway for fluids or gases to travel between components while accommodating the dynamic nature of the systems they serve 2.

Purpose of the Cummins 3930840 Flexible Hose

This Cummins part is specifically designed to connect various systems within a truck, such as the fuel, coolant, or hydraulic systems. It transports fluids essential for the operation of these systems, allowing for the necessary flexibility to accommodate the movement and vibrations inherent in truck operations. This hose ensures a reliable connection that can withstand the rigors of commercial use 3.

Key Features

The 3930840 Flexible Hose features a composition of materials that provide flexibility, durability, and resistance to the fluids it transports. Its design includes specifications that enhance performance and longevity, such as reinforced layers to prevent kinking and bursting, and smooth inner walls to ensure efficient fluid flow 4.

Benefits

Using this part offers several benefits. Its flexibility reduces the risk of leaks by accommodating movement and vibration. The hose’s durable construction enhances its longevity, even under demanding conditions. Additionally, its design facilitates ease of installation, making it a practical choice for maintenance and repair tasks 1.

Installation Considerations

When installing the 3930840 Flexible Hose, it is important to follow guidelines to ensure a secure and efficient connection. This includes using the necessary tools, such as hose clamps and wrenches, and following steps to properly align and secure the hose to the system components. Avoiding common pitfalls, such as over-tightening clamps or not allowing enough slack for movement, is crucial for the hose’s performance and longevity 2.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. Troubleshooting these problems involves inspecting the hose for visible damage, ensuring clamps are properly tightened without over-compression, and checking for proper alignment and slack. Solutions may include repairing or replacing the hose, adjusting clamps, or rerouting the hose to avoid kinks 3.

Maintenance Tips

To maintain the 3930840 Flexible Hose and ensure optimal performance, regular inspection intervals should be established. This includes checking for signs of wear, leaks, or degradation. Cleaning the hose according to manufacturer recommendations and replacing it when signs of significant wear are present will help maintain system efficiency and reliability 4.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, performance, and customer satisfaction. The company’s product range includes components and systems designed to enhance the efficiency, reliability, and sustainability of commercial vehicles.

Cummins Engine Compatibility with Part 3930840 Flexible Hose

The 3930840 Flexible Hose is designed to fit a variety of Cummins engines, ensuring compatibility and reliability across different engine models. This part is engineered to meet the specific needs of various engine configurations, providing a seamless connection that enhances performance and durability.

QSB Series Engines

The Flexible Hose 3930840 is compatible with several QSB series engines, including:

- QSB4.5 CM850 (CM2850)

- QSB5.9 44 CM550

- QSC8.3 CM850 (CM2850)

- QSL9 CM850 (CM2850)

These engines benefit from the hose’s flexibility, which helps in managing the stresses and movements inherent in these models, ensuring a secure and efficient connection.

QSL Series Engines

The QSL series engines also integrate well with the Flexible Hose 3930840, specifically:

- QSL8.9 CM2150 L141

- QSL9.3 CM2880 L113

The hose’s design accommodates the unique requirements of these engines, providing a reliable connection that enhances overall engine performance.

Other Cummins Engines

Additionally, the Flexible Hose 3930840 is suitable for:

- ISB CM550

- L8.9 L121

These engines also benefit from the hose’s flexibility and durability, ensuring a robust connection that can withstand the demands of various operating conditions.

By providing a versatile and reliable connection, the 3930840 Flexible Hose ensures that these engines operate efficiently and effectively, contributing to the overall performance and longevity of the machinery.

Part 3930840 Flexible Hose Component Usage

The 3930840 Flexible Hose is a component in various engine systems, particularly in the areas of plumbing and turbocharger integration.

Plumbing Applications

In plumbing systems, the 3930840 Flexible Hose is utilized to connect different sections of the plumbing network. Its flexibility allows for easy installation and maintenance, accommodating the natural movements and vibrations that occur within the engine system. This hose ensures a secure and leak-free connection between pipes, fittings, and other plumbing components, maintaining the integrity of the fluid transfer system. It is particularly beneficial in high-pressure and high-temperature environments, where rigid connections might fail due to thermal expansion and contraction.

Turbocharger Integration

When it comes to turbocharger systems, the 3930840 Flexible Hose plays a significant role in connecting the turbocharger to the engine’s intake and exhaust manifolds. Its flexibility is vital in managing the extreme conditions present in turbocharger applications, including high temperatures and pressures. The hose allows for the necessary movement between the turbocharger and the engine components, reducing stress on the connections and enhancing the durability of the system. Additionally, it helps in dampening vibrations, which can otherwise lead to premature wear and potential failures in the turbocharger system.

In both plumbing and turbocharger applications, the 3930840 Flexible Hose contributes to the overall efficiency and reliability of the engine system. Its design and material properties are tailored to withstand the demanding conditions encountered in these environments, ensuring consistent performance and longevity.

Conclusion

The Cummins 3930840 Flexible Hose is a critical component for maintaining the efficiency and reliability of commercial truck systems. Its flexibility, durability, and compatibility with various Cummins engines make it an essential part for plumbing and turbocharger applications. Regular maintenance and proper installation are key to ensuring the longevity and performance of this part.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ ↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ ↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ ↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.