This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

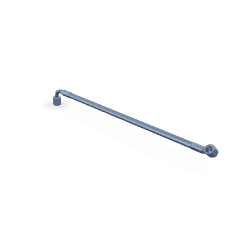

The Cummins 3937218 Flexible Hose is a specialized component designed for commercial truck operations, contributing to the efficient and reliable operation of various subsystems. Understanding its purpose and significance is crucial for maintaining and optimizing truck performance.

Basic Concepts of Flexible Hoses

Flexible hoses are essential in automotive systems for connecting different components, allowing for movement and vibration without compromising fluid pathways. They are vital for systems requiring fluid transfer, such as fuel, coolant, and hydraulic systems. In a truck’s infrastructure, flexible hoses connect rigid pipes to moving parts, accommodating the dynamic nature of vehicle operation 1.

Purpose of the 3937218 Flexible Hose

The Cummins 3937218 Flexible Hose is used to connect specific systems within a truck, facilitating fluid transport between components that may not be fixed in position relative to each other. This ensures system functionality under various operating conditions 2.

Key Features

The 3937218 Flexible Hose is characterized by features that enhance performance and durability. It is constructed from materials providing flexibility and resistance to transported fluids. The design includes elements ensuring a secure connection to other system components, contributing to its longevity and reliability in demanding environments 3.

Benefits

Utilizing the Cummins 3937218 Flexible Hose offers several advantages. It improves system reliability by reducing the risk of leaks and maintaining fluid integrity throughout the system. The hose’s design and material composition enhance the overall performance of the truck, ensuring efficient operation of fluid transfer systems.

Installation Considerations

When installing the Cummins 3937218 Flexible Hose, it is important to follow guidelines to ensure proper integration with the truck’s systems. This includes aligning the hose correctly, securing it in place using appropriate methods, and verifying compatibility with existing components to prevent issues during operation.

Troubleshooting Common Issues

Flexible hoses, including the 3937218, may encounter problems such as leaks or degradation over time. Identifying these issues early can prevent more significant system failures. Common troubleshooting methods involve inspecting the hose for signs of wear, checking connections for tightness, and addressing any fluid leaks promptly to maintain system integrity.

Maintenance Tips

Regular maintenance of the Cummins 3937218 Flexible Hose is key to prolonging its lifespan. This includes routine inspections for damage, cleaning the hose and its connections, and monitoring for any signs of fluid leaks. Knowing when to replace the hose can also prevent unexpected failures and ensure continuous, reliable operation of the truck’s systems.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products that include engines, filtration systems, and aftermarket parts. The company has a history of innovation and quality, contributing to its reputation for producing reliable and high-performance components for the trucking sector.

Compatibility with Cummins Engines

The Cummins part 3937218, a Flexible Hose, is designed to fit seamlessly with a variety of Cummins engines, ensuring efficient fluid transfer and maintaining the integrity of the engine’s cooling and fuel systems. This part is engineered to meet the specific needs of the following engines:

-

6B5.9 and 6C8.3: These engines benefit from the flexible hose’s ability to withstand the high pressures and temperatures typical of these models, ensuring smooth operation and reducing the risk of leaks.

-

B4.5: The flexible hose is compatible with the B4.5 engine, providing a reliable connection that can endure the engine’s operational demands.

-

ISB CM550: This engine model is designed to integrate the flexible hose, which helps in managing the fluid dynamics efficiently, contributing to the engine’s overall performance.

-

QSB3.9 30 CM550, QSB5.9 30 CM550, and QSB5.9 44 CM550: These engines, part of the QSB series, are equipped with the flexible hose to ensure optimal fluid flow and pressure management. The hose’s flexibility and durability make it an ideal component for these engines, enhancing their operational efficiency and longevity.

Each of these engines, despite their differences, relies on the flexible hose to maintain the necessary fluid pathways, ensuring that the engine operates smoothly and efficiently.

Role of Part 3937218 Flexible Hose in Compressor and Air Systems

The part 3937218 Flexible Hose is integral to the efficient operation of both compressor and air systems. In compressor systems, this hose facilitates the transfer of compressed air from the compressor to various components that require pressurized air for operation. Its flexibility allows it to navigate through the complex layout of the engine bay, ensuring a secure and leak-free connection between the compressor and its downstream components.

In air systems, particularly those involving air suspension or air brake systems, the 3937218 Flexible Hose plays a key role in delivering compressed air to the actuators or cylinders. This ensures that the system can respond quickly to control inputs, maintaining vehicle stability in suspension systems or ensuring reliable braking performance in air brake systems.

Additionally, the hose’s design accommodates the dynamic movements and vibrations inherent in engine compartments, reducing the risk of fatigue or failure over time. This reliability is essential for maintaining the performance and safety of the vehicle’s air-operated systems.

Conclusion

The Cummins 3937218 Flexible Hose is a critical component in the operation of commercial trucks, ensuring efficient and reliable fluid transfer across various systems. Its design and material composition contribute to the overall performance and longevity of the truck’s systems. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring continuous and reliable operation of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.