This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3979279 Flexible Hose is a component designed for use in commercial truck operations. It serves as a vital link in various systems within the truck, facilitating the transfer of fluids or gases. Its role is significant in maintaining the efficiency and reliability of truck operations.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in automotive and other systems to transfer fluids or gases. They are designed to accommodate movement and vibration, which are common in vehicle operations. Unlike rigid pipes, flexible hoses can bend and flex without breaking, making them suitable for applications where movement is inevitable. They are typically made from materials that can withstand pressure, temperature variations, and chemical exposure 1.

Purpose and Role in Truck Operation

This Cummins part plays a specific role in truck operations by connecting various systems and enabling the transfer of fluids or gases between them. It is used in applications where flexibility is required to accommodate the movement of the truck’s components. The hose may transport coolant, fuel, or other fluids, depending on its application within the truck’s system 2.

Key Features

The 3979279 Flexible Hose is characterized by several key features that enhance its performance and longevity. These include its material composition, which is designed to resist wear and tear, as well as chemical and temperature extremes. The hose’s flexibility allows it to bend and twist without compromising its integrity, while its durability ensures it can withstand the rigors of commercial truck operations. Design elements such as reinforced ends and smooth inner walls contribute to its efficient function 3.

Benefits

This part offers several benefits over rigid hoses. Its flexibility reduces stress on connected components, which can lead to a longer lifespan for those parts. The hose’s design also allows for easier installation and maintenance. In harsh operating environments, the hose’s durability ensures reliable performance, contributing to the overall efficiency of the truck 4.

Installation Considerations

When installing the 3979279 Flexible Hose, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes using the correct fittings, securing the hose with appropriate methods to prevent movement, and ensuring that the hose is aligned correctly with the systems it connects. Attention to these details during installation can prevent issues down the line.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. To address these problems, it is important to regularly inspect the hose for signs of wear or damage. If a leak is detected, the source should be identified and repaired or replaced as necessary. Kinks can often be resolved by repositioning the hose, while degradation may require replacement of the hose to maintain system integrity.

Maintenance Tips

Regular maintenance of the 3979279 Flexible Hose is key to ensuring optimal performance and longevity. This includes inspecting the hose for signs of wear, checking for leaks, and cleaning the hose as needed. Maintenance schedules should be established based on the truck’s usage and operating conditions. When signs of significant wear or damage are present, consideration should be given to replacing the hose to prevent system failure.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Cummins Flexible Hose 3979279 Compatibility

The Cummins Flexible Hose part number 3979279 is designed to integrate seamlessly with various engine models, ensuring optimal performance and reliability. This part is engineered to withstand the rigors of engine operation, providing a durable connection that can endure the stresses of high pressure and temperature variations.

Engine Compatibility

-

6C8.3 Series

- The 6C8.3 engine series benefits from the flexibility and resilience of the 3979279 hose. This part is specifically engineered to fit the unique requirements of the 6C8.3 engines, ensuring a secure and leak-free connection.

-

Other Cummins Engines

- While the primary focus is on the 6C8.3 series, the 3979279 hose is also compatible with other Cummins engines. Its design allows it to adapt to various engine configurations, making it a versatile choice for multiple applications.

Installation and Usage

When installing the Cummins Flexible Hose 3979279, it is crucial to follow proper procedures to ensure a secure fit and optimal performance. This includes:

- Correct Sizing: Ensuring the hose is the appropriate size for the connection points on the engine.

- Proper Routing: Avoiding sharp bends and kinks that can compromise the hose’s integrity.

- Secure Fastening: Using the correct clamps and fittings to maintain a tight seal and prevent leaks.

By adhering to these guidelines, the 3979279 hose can provide long-lasting performance and reliability in Cummins engines.

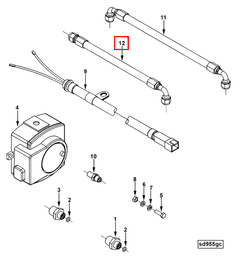

Role of Part 3979279 Flexible Hose in Engine Systems

The part 3979279 Flexible Hose is an integral component in the fluid dynamics of engine systems, specifically in the management and transfer of coolant. This hose is designed to connect various components within the engine’s cooling system, ensuring efficient operation and longevity of the engine.

Integration with Sensors

In modern engine systems, sensors play a pivotal role in monitoring various parameters to ensure optimal performance. The 3979279 Flexible Hose facilitates the connection between these sensors and the coolant system. By providing a reliable pathway for coolant flow, it enables sensors to accurately measure temperature and other vital metrics. This connection is essential for the Engine Control Unit (ECU) to make real-time adjustments, enhancing engine efficiency and preventing overheating.

Coolant Level Management

The 3979279 Flexible Hose also plays a significant role in maintaining the correct coolant level within the engine. It connects the coolant reservoir to the engine block and radiator, allowing for the circulation of coolant throughout the system. This ensures that the engine remains at an optimal operating temperature, preventing both overheating and undercooling. The hose’s flexibility accommodates the natural expansion and contraction of the coolant as it heats up and cools down, maintaining a consistent flow and pressure within the system.

Enhanced System Reliability

By integrating the 3979279 Flexible Hose into the engine’s cooling system, engineers and mechanics can enhance the overall reliability of the engine. The hose’s durable construction and flexible design reduce the risk of leaks and failures, which are common issues with rigid hoses. This reliability is particularly important in high-stress environments where the engine is subjected to extreme temperatures and pressures.

Improved Maintenance and Repair

The use of the 3979279 Flexible Hose simplifies maintenance and repair procedures. Its flexible nature allows for easier installation and removal, reducing the time and effort required for routine checks and replacements. This not only improves efficiency in maintenance operations but also minimizes downtime, ensuring that engines remain operational with minimal interruption.

Conclusion

The 3979279 Flexible Hose is a vital component in the engine’s cooling system, facilitating the efficient transfer of coolant and integration with sensors. Its role in maintaining coolant levels, enhancing system reliability, and simplifying maintenance makes it an indispensable part of modern engine systems.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

David C Barton and John D Fieldhouse, Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, Elsevier, 2009.

↩ -

Frank Sander, Diesel Mechanics, First Edition, Global Media, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.