This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4003825 Flexible Hose is a component designed for use in commercial trucks, manufactured by Cummins Inc. This hose serves a role in the truck’s fluid transfer systems, facilitating the movement of various fluids necessary for the operation of the vehicle. Flexible hoses are integral to the overall truck system, providing a means to connect different parts of the system while accommodating movement and vibration that rigid pipes cannot 1.

Basic Concepts of Flexible Hoses

Flexible hoses are conduits used in fluid transfer systems to convey liquids or gases from one point to another. They are constructed from materials that allow them to bend and flex without compromising the flow of the fluid. Common materials include rubber, thermoplastic, and metal braids, each offering different levels of flexibility, durability, and resistance to various conditions. The use of flexible hoses over rigid pipes offers several advantages, including the ability to absorb vibration, accommodate thermal expansion, and provide a more straightforward installation process 2.

Purpose of the Cummins 4003825 Flexible Hose

This Cummins part is specifically designed to play a role in the fluid transfer systems of commercial trucks. It connects various components within the system, allowing for the transport of fluids such as coolant, fuel, or hydraulic fluid. By providing a flexible connection, it ensures that the flow of these fluids is maintained even when the truck is in motion or subjected to vibrations 3.

Key Features

The 4003825 Flexible Hose is characterized by several key features that enhance its performance and durability. Its design incorporates materials that offer resistance to abrasion and environmental conditions, ensuring longevity. The hose is constructed to withstand the pressures and temperatures associated with its intended use, and it may include reinforcement layers to improve its strength and flexibility 4.

Benefits

Utilizing this part offers several advantages. Its flexibility allows it to absorb vibrations and movements that could otherwise lead to stress on the system. This flexibility also contributes to a reduction in noise and potential leaks. Additionally, the hose’s resistance to abrasion and environmental factors enhances its reliability and safety in fluid transfer applications 5.

Installation Considerations

When installing the 4003825 Flexible Hose, it is important to follow guidelines and best practices to ensure proper fitting and securement. This includes verifying compatibility with the truck’s system, using the correct fittings, and employing methods to secure the hose in place. Attention to these details helps maintain the integrity of the fluid transfer system and ensures optimal performance 6.

Troubleshooting and Maintenance

Common issues with flexible hoses can include leaks, abrasion damage, and degradation over time. Diagnosing these problems involves inspecting the hose for signs of wear, checking connections for tightness, and ensuring there are no obstructions in the fluid flow. Regular maintenance, such as cleaning and checking for damage, can help ensure the longevity and optimal performance of the hose. Safety precautions, including wearing protective gear and ensuring the system is depressurized before maintenance, are also important 7.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance truck components, Cummins has built a reputation for excellence. The company’s focus on advancing technology and meeting the needs of its customers underscores its position as a leader in the field 8.

Compatibility

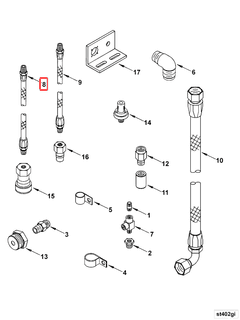

The Cummins Flexible Hose part number 4003825 is engineered to fit seamlessly with various engine models, ensuring optimal performance and durability. This hose is designed to connect different components within the engine system, facilitating the transfer of fluids or gases while accommodating the natural movements and vibrations of the engine.

K19 Engine Group

For the K19 engine series, the Flexible Hose 4003825 is a component that ensures the smooth operation of the engine. It is specifically designed to fit the unique architecture of the K19 engines, providing a reliable connection that can withstand the rigors of continuous operation. The hose’s flexibility allows it to adapt to the engine’s movements, reducing the risk of wear and tear and extending the lifespan of the engine components it connects.

The Cummins Flexible Hose 4003825 is engineered to meet the stringent requirements of the K19 engines, ensuring that it can handle the high pressures and temperatures typical of these engines. Its robust construction and precise fitment make it a part of the engine’s overall performance and reliability.

Role of Part 4003825 Flexible Hose in Engine Systems

The part 4003825 Flexible Hose is a component in various engine systems, facilitating the smooth operation and integration of multiple subsystems. Its primary function is to provide a flexible connection between rigid components, accommodating movement and vibration while maintaining a secure and leak-free passage for fluids.

Integration with Accessories

In engine systems, the flexible hose is often used to connect accessories such as pumps, filters, and sensors to the main plumbing lines. This flexibility ensures that even as the engine components shift slightly during operation, the connections remain intact, preventing leaks and maintaining efficient fluid flow.

Air Starting Systems

For air starting systems, the flexible hose plays a role in connecting the air supply to the engine’s air start valves. This setup allows for the necessary air pressure to be delivered without the risk of rigid pipes cracking or breaking under the stress of engine vibrations.

Connection Brackets

When used with connection brackets, the flexible hose provides a robust yet adaptable link between the bracket and the engine’s plumbing. This is particularly important in systems where the bracket may need to be adjusted or moved during maintenance, ensuring that the hose can flex without compromising the integrity of the connection.

Engine Oil Primer

In the context of an engine oil primer, the flexible hose is utilized to connect the primer pump to the engine’s oil system. This ensures that oil can be efficiently circulated through the engine before start-up, reducing wear and tear on moving parts by ensuring they are properly lubricated from the onset.

Prelube Starter Systems

For prelube starter systems, the flexible hose is integral in connecting the prelube pump to the engine’s lubrication system. This connection ensures that the engine receives a steady supply of lubricant before the main oil pump engages, which is essential for preventing metal-to-metal contact and subsequent damage during the initial cranking phase.

Plumbing Applications

Across various plumbing applications within engine systems, the flexible hose serves as a versatile connector. Whether linking different sections of the plumbing or providing a flexible joint in a rigid pipe system, its role is to enhance the system’s durability and reliability under operational stress.

Pre-lube Systems

In pre-lube systems, the flexible hose is used to connect the pre-lube pump to the engine, ensuring that critical components are lubricated before the engine reaches operating temperature. This preemptive lubrication is key to extending the lifespan of the engine and maintaining optimal performance.

Conclusion

The 4003825 Flexible Hose, through its versatile applications, ensures that engine systems operate smoothly, efficiently, and with minimal risk of fluid leaks or connection failures. Its flexibility and durability make it a valuable component in the intricate network of an engine’s subsystems.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Cummins Inc. Service Manual (5411223). B6.7 CM2350 B121B, Cummins Inc.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Cummins Inc. Service Manual (5411223). B6.7 CM2350 B121B, Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.