This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4019401 Flexible Hose is a component designed for use in commercial trucks. It facilitates the transfer of fluids or gases within the truck’s system, engineered to withstand demanding conditions encountered in commercial trucking, ensuring reliable performance and contributing to the overall efficiency of the vehicle 2.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in various automotive and industrial applications to transport fluids or gases between different parts of a system. They are designed to offer flexibility, allowing them to bend and move without compromising the flow of the substance they carry. In automotive systems, flexible hoses are commonly used for fuel lines, coolant systems, and brake systems, among others. Their ability to accommodate movement and vibration makes them indispensable in applications where rigid pipes would be impractical 4.

Purpose of the Cummins 4019401 Flexible Hose

This Cummins part enables the transfer of fluids or gases between components that may move relative to each other. It is integral to maintaining the integrity of the system by ensuring a consistent and reliable flow, which is essential for the proper operation of the truck. Its design allows it to absorb vibrations and movements, reducing the risk of damage to the hose and the system it serves 1.

Key Features

The Cummins 4019401 Flexible Hose is characterized by several key features that enhance its performance and longevity. These include its material composition, selected for durability and resistance to the substances it carries, as well as external conditions. The hose’s flexibility allows it to bend and twist without kinking, ensuring a smooth flow. Additionally, its design specifications are tailored to meet the specific demands of commercial truck applications, ensuring it can withstand high pressures and temperatures 3.

Benefits

This part offers several advantages that contribute to its popularity in commercial truck applications. These include a reduced risk of leaks due to its robust construction and flexibility, enhanced durability under varying conditions, and improved overall system efficiency. The hose’s ability to accommodate movement and vibration without compromising performance helps to minimize maintenance needs and extend the lifespan of the truck’s system 2.

Installation Considerations

Proper installation of the Cummins 4019401 Flexible Hose is crucial for ensuring optimal performance and longevity. Guidelines and best practices for installation include ensuring the hose is correctly routed to avoid sharp bends or kinks, securing it in place with appropriate clamps, and checking for proper alignment with the components it connects. Following these guidelines helps to prevent common issues such as leaks or premature wear 1.

Troubleshooting Common Issues

Common problems associated with flexible hoses, such as leaks or wear, can often be traced back to installation issues or environmental factors. Troubleshooting steps may include inspecting the hose for signs of damage or wear, checking the tightness of clamps and connections, and ensuring the hose is not subjected to excessive heat or pressure. Addressing these issues promptly can help to maintain the integrity of the system and prevent more serious problems 4.

Maintenance Tips

Regular maintenance practices can help to prolong the life of the Cummins 4019401 Flexible Hose. Recommendations include conducting periodic inspections for signs of wear or damage, checking the tightness of clamps and connections, and cleaning the hose as necessary to remove any buildup that could affect its performance. Adhering to these maintenance tips can help to ensure the hose continues to operate efficiently and reliably 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and reliability, Cummins has established a strong reputation in the commercial truck industry for producing components that meet the demanding requirements of heavy-duty applications. The company’s commitment to quality and performance is evident in its wide range of products, including the Cummins 4019401 Flexible Hose 2.

Cummins Part 4019401: Flexible Hose Compatibility with Engine Models

The Cummins part 4019401, a flexible hose, is designed to integrate seamlessly with a variety of engine models, ensuring optimal performance and durability. This part is engineered to meet the specific requirements of the following engine series:

6B5.9 Engines

The 6B5.9 engines benefit from the flexibility and resilience of the 4019401 hose. This component is crucial for maintaining the integrity of the engine’s fluid systems, providing a reliable connection that can withstand the rigors of continuous operation.

QSC8.3 Engines

In the QSC8.3 engines, the 4019401 flexible hose plays a pivotal role in the engine’s fluid management system. Its design ensures that it can handle the dynamic stresses encountered in these engines, contributing to the overall efficiency and longevity of the engine.

CM850 (CM2850) Engines

For the CM850 (CM2850) engines, the 4019401 hose is integral to the engine’s cooling and fluid transfer systems. Its flexibility and strength make it an essential component, ensuring that the engine operates smoothly and efficiently under various conditions.

By providing a versatile and robust connection, the Cummins part 4019401 flexible hose supports the operational needs of these engines, enhancing their performance and reliability 3.

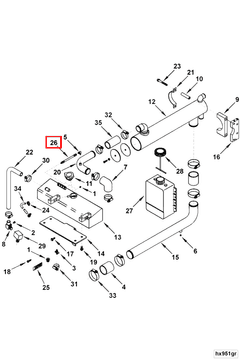

Role of Part 4019401 Flexible Hose in Engine Systems

The part 4019401 Flexible Hose is integral to the efficient operation of various engine systems, particularly in the context of the heat exchanger. This hose facilitates the transfer of fluids between different components, ensuring that the heat exchanger can effectively manage thermal loads within the engine.

In the heat exchanger system, the flexible hose connects the heat exchanger to other critical components such as the radiator and the engine block. This connection allows for the circulation of coolant, which absorbs heat from the engine and transfers it to the radiator for dissipation. The flexibility of the hose accommodates the vibrations and movements inherent in engine operation, maintaining a secure and leak-free connection.

Additionally, the hose plays a role in the overall thermal management of the engine by ensuring consistent fluid flow. This consistent flow is essential for maintaining optimal engine temperature, which in turn enhances performance and longevity of the engine components.

The integration of part 4019401 Flexible Hose within these systems underscores its importance in facilitating efficient heat exchange and fluid dynamics, contributing to the stable and reliable operation of the engine 4.

Conclusion

The Cummins 4019401 Flexible Hose is a critical component in the operation of commercial trucks, designed to withstand the demanding conditions of heavy-duty applications. Its flexibility, durability, and ability to accommodate movement and vibration make it an indispensable part of the truck’s fluid transfer systems. Proper installation, maintenance, and troubleshooting are essential to ensure the hose’s longevity and the overall efficiency of the vehicle. Cummins’ commitment to quality and performance is reflected in the design and functionality of this part, making it a reliable choice for commercial truck applications.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ ↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ ↩ ↩ -

Cummins Inc. Owners Manual for QSL9 M CM2250 L106. Bulletin Number 4358341.

↩ ↩ ↩ -

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.