This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

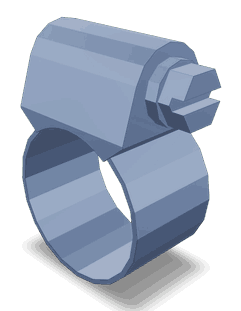

The Hose Clamp 43828, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. Designed for commercial trucks, this part secures hoses within various systems, ensuring their integrity and efficiency.

Basic Concepts of Hose Clamps

Hose clamps are essential for securing hoses to fittings, preventing leaks, and maintaining system integrity. They are typically made from durable materials like stainless steel, aluminum, or plastic, chosen for their resistance to corrosion and ability to withstand high temperatures and pressures 1.

Functionality of Hose Clamp 43828

This Cummins part operates through a screw mechanism that allows for adjustable clamping force. This feature ensures a secure and consistent seal around the hose and fitting, crucial for the systems in which it is used 2.

Role in Truck Operation

In truck operation, the Hose Clamp 43828 is vital for several critical systems, including fuel, coolant, and pneumatic systems. It ensures efficient and leak-free transportation of fluids and gases, contributing to the truck’s overall performance and reliability 3.

Key Features

The Hose Clamp 43828 is known for its robust material composition, typically high-grade metals, ensuring strength and durability. Its design includes a corrosion-resistant finish and a mechanism for precise adjustment of clamping force, enhancing its performance in demanding applications.

Benefits

Using the Hose Clamp 43828 offers benefits such as enhanced reliability, ease of installation, and durability. Its design allows for quick and secure hose attachment, reducing maintenance downtime. The clamp’s durability ensures long-term performance, contributing to the efficiency and safety of truck operations.

Troubleshooting and Maintenance

Common issues with hose clamps include corrosion, loosening, or damage from harsh conditions. Troubleshooting involves inspecting for wear or corrosion, ensuring proper tightening, and replacing if necessary. Regular maintenance, like cleaning and inspection, ensures the clamp’s longevity and effectiveness.

About Cummins

Cummins is a leading manufacturer in the automotive and heavy-duty truck industry, renowned for its commitment to quality and innovation. Their products, including the Hose Clamp 43828, are designed for durability, efficiency, and compatibility with a wide range of truck systems.

Cummins Engine Compatibility with Hose Clamp 43828

This Cummins part is versatile, fitting a wide range of Cummins engines. It provides a secure and reliable seal for various hose connections, ensuring efficient and safe engine operation. Compatible engines include 4B3.9, 6B5.9, 6C8.3, B5.6 CM2670 B152B, B5.9 G, B5.9 GAS PLUS CM556, B6.7 CM2670 B153B, G8.3, G855, G855 CM558, GTA855 CM558 (CM2358) G101, ISB CM550, ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, ISBE4 CM850, ISC CM2150, ISC CM554, ISC CM850, ISC8.3 CM2250, ISG12 G CMOH6.0 G111, ISL CM2150, ISL CM554, ISL9 CM2150 SN, ISL9 CM2250, and ISX CM570.

Role of Part 43828 Hose Clamp in Engine Systems

This part is instrumental in securing and maintaining the integrity of various hose connections within engine systems. Its applications include air and breather systems, CCV system and retrofit kits, coolant and heating systems, fuel and vacuum systems, intake and exhaust manifolds, and additional applications like mounting kits and corrosion-resistant brackets. It ensures secure and leak-free connections, enhancing engine reliability and performance.

Conclusion

The Hose Clamp 43828 by Cummins is a vital component in commercial truck systems, offering durability, ease of use, and compatibility with a wide range of engines. Its role in securing hose connections is crucial for the efficient and reliable operation of various engine systems.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.