The Cummins 3071049 Hump Hose is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the efficient transfer of fluids within the truck’s system, ensuring optimal performance and reliability. This part is significant in the operation of commercial trucks as it contributes to the overall efficiency and durability of the vehicle’s fluid systems.

Purpose and Function

The Cummins 3071049 Hump Hose plays a role in the truck’s fluid transfer system by connecting various components, allowing for the smooth flow of fluids such as coolant, oil, or other necessary liquids 1. This hose is integral to maintaining the proper function of the engine and other systems by ensuring that fluids are delivered where needed without leaks or restrictions. Its function contributes to the overall performance and efficiency of the vehicle by supporting consistent fluid levels and pressure 2.

Design and Construction

The Cummins 3071049 Hump Hose is constructed using high-quality materials that are resistant to wear, corrosion, and high temperatures. The hose typically features reinforced layers to enhance its durability and flexibility. These materials and construction techniques ensure that the hose can withstand the rigors of commercial truck operation, providing a reliable connection between critical components. Unique design elements, such as specialized fittings and reinforced sections, further enhance its performance and longevity 3.

Benefits

The Cummins 3071049 Hump Hose offers several advantages. It contributes to improved fuel efficiency by ensuring that fluids are delivered efficiently throughout the system, reducing the likelihood of leaks that can lead to inefficiencies. Additionally, by maintaining proper fluid levels and pressure, the hose helps in reducing emissions, as the engine operates more cleanly and efficiently. Its durable construction also means enhanced longevity, reducing the frequency of replacements and maintenance costs. Furthermore, the hose’s design allows for easier installation and maintenance, minimizing downtime for commercial trucks.

Installation and Compatibility

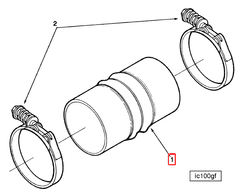

Proper installation of the Cummins 3071049 Hump Hose is crucial for ensuring its effectiveness and longevity. Installation guidelines typically include ensuring that the hose is correctly aligned with the fittings, using appropriate clamps to secure it in place, and checking for any signs of damage or wear before use. Compatibility information is vital for ensuring that the hose fits the specific truck model and engine type, guaranteeing optimal performance and reliability.

Maintenance and Troubleshooting

Maintaining the Cummins 3071049 Hump Hose involves regular inspections for signs of wear, cracks, or leaks. Best practices include checking the hose during routine maintenance intervals and replacing it if any damage is detected. Common issues that may arise include hose degradation due to exposure to extreme temperatures or chemical contaminants. Troubleshooting steps may involve inspecting the hose for proper alignment and secure fitting, ensuring that clamps are tight, and replacing the hose if necessary to prevent fluid leaks and system inefficiencies.

Performance Impact

The Cummins 3071049 Hump Hose affects the overall performance of the truck by ensuring that fluids are transferred efficiently throughout the system. This efficiency can lead to improvements in engine performance, as consistent fluid levels and pressure are maintained. Additionally, by reducing the likelihood of leaks and inefficiencies, the hose contributes to lower emissions, supporting environmental compliance. Enhanced fluid management also contributes to driver comfort by ensuring that the truck operates smoothly and reliably.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and efficient components. The company’s extensive product range and commitment to innovation have made it a preferred choice for commercial truck manufacturers and operators worldwide.

Hump Hose Compatibility with Cummins Engines

The Cummins part number 3071049, known as the Hump Hose, is designed to fit a variety of Cummins engines. This hose is an essential component in the engine’s cooling system, ensuring proper fluid flow and maintaining optimal engine performance. Below is a detailed description of the compatibility of the Hump Hose with various Cummins engines.

6 Series Engines

- 6B5.9

- 6C8.3

- B5.9 G

- B5.9 GAS PLUS CM556

- C8.3 G

The Hump Hose is compatible with the 6 Series engines, which include the 6B5.9, 6C8.3, B5.9 G, B5.9 GAS PLUS CM556, and C8.3 G. These engines are known for their robust performance and reliability, often used in various industrial and commercial applications.

C Series Engines

- C GAS PLUS CM556

The Hump Hose also fits the C GAS PLUS CM556 engine. This engine is part of the C Series, which is designed for high-performance applications requiring durability and efficiency.

ISB Series Engines

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE4 CM850

The ISB Series engines, including the ISB CM2150, ISB CM550, ISB CM850, ISB/ISD6.7 CM2150 SN, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118, ISBE CM2150, and ISBE4 CM850, are designed for a wide range of applications from light-duty to heavy-duty operations. The Hump Hose is compatible with all these models, ensuring seamless integration and optimal performance.

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

The Hump Hose is also suitable for the ISC Series engines, which include the ISC CM2150, ISC CM554, ISC CM850, and ISC8.3 CM2250. These engines are known for their efficiency and reliability, making them a popular choice for various applications.

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

The ISL Series engines, such as the ISL CM2150, ISL CM554, ISL G CM2180, ISL9 CM2150 SN, ISL9 CM2250, and ISL9.5 CM2880 L138, benefit from the Hump Hose’s compatibility. These engines are designed for heavy-duty applications, providing the power and durability needed for demanding tasks.

The Hump Hose’s compatibility with these engines ensures that it can be used across a wide range of applications, providing a reliable and efficient solution for maintaining the engine’s cooling system.

Role of Part 3071049 Hump Hose in Engine Systems

The 3071049 Hump Hose is an integral component in various engine systems, facilitating efficient operation and performance. Its primary function is to manage the flow of air and coolant within the engine, ensuring optimal conditions for combustion and temperature regulation.

Air Intake System

In the air intake system, the Hump Hose connects the air intake hose to the air intake connection. This connection is vital for directing clean, filtered air from the air cleaner into the engine. The Hump Hose ensures a secure and leak-free pathway, maintaining the integrity of the air-fuel mixture. Its design accommodates the necessary bends and angles within the engine bay, allowing for a smooth and uninterrupted airflow.

Air Transfer System

Within the air transfer system, the Hump Hose plays a role in connecting the air transfer hose to the air transfer connection. This system is responsible for redistributing air within the engine compartment, aiding in the ventilation of hot air and improving overall engine efficiency. The Hump Hose’s durable construction withstands the pressures and temperatures associated with air transfer, ensuring reliable performance.

Cooling System

In the cooling system, the Hump Hose is used in conjunction with the cooling system kit and heat exchanger. It connects the hose to the heat exchanger, allowing for the efficient transfer of coolant. This connection is essential for dissipating heat generated by the engine, maintaining optimal operating temperatures. The Hump Hose’s flexibility and resilience are key in withstanding the thermal cycles and pressure variations within the cooling system.

Radiator Connection

The Hump Hose also facilitates the connection between the radiator and other components of the cooling system. By linking the radiator to the heat exchanger and other critical points, it ensures a consistent flow of coolant. This connection is fundamental for the radiator’s ability to dissipate heat effectively, preventing engine overheating and ensuring prolonged engine life.

Overall Integration

The 3071049 Hump Hose is a versatile component that integrates seamlessly into various engine systems. Its role in managing air and coolant flow underscores its importance in maintaining engine performance and reliability. Engineers and mechanics appreciate its durability, flexibility, and ability to accommodate complex engine layouts, making it a valuable asset in both maintenance and upgrade scenarios.

Conclusion

The Cummins 3071049 Hump Hose is a critical component in the efficient operation of commercial trucks. Its design and construction ensure durability and flexibility, contributing to improved fuel efficiency, reduced emissions, and enhanced engine performance. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engines are essential for maximizing its benefits. The Hump Hose’s role in managing air and coolant flow within engine systems highlights its importance in maintaining overall vehicle reliability and performance.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Zhan, Quansheng, Eben, Shengbo, Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.