3071052

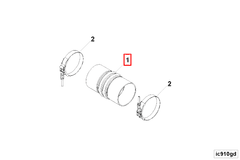

Hump Hose

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3071052 Hump Silicone Hose is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s system, contributing to the overall efficiency and performance of the truck. Understanding its purpose and significance can help in maintaining and optimizing the truck’s operation.

Basic Concepts and Functionality

A Hump Silicone Hose is a type of hose used in automotive and heavy-duty truck systems. It is designed to handle the transfer of fluids or gases under varying conditions of pressure and temperature. Within the truck’s system, the hose connects different components, allowing for the smooth flow of substances such as air or exhaust gases. Its role is vital in ensuring that the system operates efficiently without leaks or disruptions 1.

Purpose of the 3071052 Hump Silicone Hose

This Cummins part is specifically engineered to function within the truck’s air intake or exhaust system. It plays a role in directing air into the engine or expelling exhaust gases from it. By providing a durable and flexible connection between components, it helps maintain the integrity of the system, ensuring that air or gases are transferred effectively 2.

Key Features

The 3071052 Hump Silicone Hose is constructed from high-quality silicone, which offers several advantages. Silicone is known for its flexibility, allowing the hose to bend and move without cracking. It also provides excellent resistance to high temperatures, which is crucial in the demanding environment of a commercial truck’s engine compartment. Additionally, the hose is designed with reinforced ends to ensure a secure fit and prevent leaks 3.

Benefits

The use of the 3071052 Hump Silicone Hose offers several benefits. Its durable construction ensures longevity, reducing the need for frequent replacements. The hose’s resistance to high temperatures helps it withstand the extreme conditions within the engine compartment. Furthermore, its flexibility allows it to accommodate the movements and vibrations inherent in a truck’s operation, contributing to a more reliable system 4.

Installation Considerations

When installing the 3071052 Hump Silicone Hose, it is important to follow guidelines to ensure proper fit and function. This includes ensuring that the hose is correctly aligned with the components it connects and that all connections are secure. Cummins may provide specific recommendations for installation, which should be adhered to for optimal performance.

Troubleshooting Common Issues

Common issues with the 3071052 Hump Silicone Hose may include leaks or cracks in the hose. These can often be identified through visual inspection or by observing changes in the truck’s performance. Troubleshooting steps may involve checking the connections for tightness, inspecting the hose for signs of wear or damage, and replacing the hose if necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the 3071052 Hump Silicone Hose, regular maintenance is recommended. This includes periodic inspection for signs of wear, checking connections for tightness, and replacing the hose if it shows signs of damage or deterioration. Following these maintenance routines can help prevent issues and ensure the hose continues to function effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s products, including the 3071052 Hump Silicone Hose, are designed with a focus on durability, performance, and reliability, reflecting Cummins’ dedication to excellence in the field.

Compatibility of Cummins Part 3071052 with Various Engine Models

The Cummins part 3071052, a Hump Silicone Hose, is designed to fit seamlessly within a range of engine models. This part is integral to the engine’s operation, ensuring proper fluid management and system integrity. Below is a detailed look at the compatibility of this part with specific engine models:

Cummins 4B3.9 and 6B5.9 Engines

The Hump Silicone Hose part 3071052 is compatible with both the 4B3.9 and 6B5.9 engines. These engines, known for their robust performance and reliability, benefit from the precise fit and durability of the silicone hose. The hose ensures that the fluid pathways remain unobstructed, which is crucial for maintaining engine efficiency and longevity.

Cummins 6C8.3 and B5.9 G Engines

Similarly, the 6C8.3 and B5.9 G engines also utilize the part 3071052. These engines, which are part of the Cummins lineup, are designed for heavy-duty applications. The silicone hose is engineered to withstand the high temperatures and pressures typical of these engines, ensuring that the fluid systems operate smoothly and without leaks.

Cummins QSB3.9 and QSB5.9 Engines

The QSB3.9 and QSB5.9 engines are another set of models that integrate the part 3071052. These engines are known for their versatility and are used in a variety of applications, from agricultural to industrial use. The hose’s design allows for easy installation and maintenance, making it a practical choice for these engines.

Cummins QSB3.9 30 CM550 and QSB5.9 30 CM550 Engines

Lastly, the QSB3.9 30 CM550 and QSB5.9 30 CM550 engines are equipped with the part 3071052. These engines are part of the Cummins QSB series, which is renowned for its power and efficiency. The hose’s compatibility with these models ensures that the engines can perform at their best, with reliable fluid management systems.

In summary, the Cummins part 3071052 is a versatile and essential component for a range of engine models, ensuring optimal performance and reliability across various applications.

Role of Part 3071052 Hump Silicone Hose in Engine Systems

The 3071052 Hump Silicone Hose is an essential component in various engine systems, particularly in the air intake and plumbing systems.

In the air intake system, this hose facilitates the smooth transition of air from the air filter to the throttle body. Its hump design allows it to navigate around other engine components without kinking, ensuring a consistent airflow. This consistent airflow is vital for optimal engine performance, as it ensures that the correct air-fuel mixture reaches the combustion chambers.

Within the plumbing system, the 3071052 Hump Silicone Hose is often used to connect various components such as the intercooler, turbocharger, and other air management devices. Its flexible silicone material allows it to withstand high temperatures and pressures, making it ideal for these applications. The hose’s design also helps in reducing vibrations and stress on the connections, which can prolong the lifespan of the entire system.

Overall, the 3071052 Hump Silicone Hose plays a significant role in maintaining the efficiency and reliability of engine systems by ensuring smooth and uninterrupted airflow and fluid dynamics.

Conclusion

The Cummins 3071052 Hump Silicone Hose is a critical component in the operation of commercial trucks, particularly within the air intake and exhaust systems. Its durable construction, resistance to high temperatures, and flexibility make it an ideal choice for ensuring efficient and reliable engine performance. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall longevity and performance of the truck’s engine system.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Peters, George, and Barbara J Peters. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.