This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3911725 Molded Hose is a component manufactured by Cummins, a well-established name in the commercial truck industry. This hose is integral to the fluid transfer systems in commercial trucks, ensuring efficient and reliable operation. Understanding its role, features, and benefits can enhance the maintenance and performance of these vehicles.

Basic Concepts of Molded Hoses

Molded hoses are specialized components designed for fluid transfer in various systems. They are constructed using a combination of synthetic rubber and reinforcement materials, which provide durability and flexibility. These hoses are molded into specific shapes and sizes to fit precisely within the systems they serve, ensuring a secure and leak-free connection. In fluid transfer systems, molded hoses play a role by conveying liquids or gases from one point to another, maintaining system integrity and performance 1.

Role of the 3911725 Molded Hose in Truck Operation

This Cummins part is designed to operate within the fluid transfer systems of commercial trucks. It is part of the engine’s cooling system, where it facilitates the movement of coolant between the engine and the radiator. This hose helps maintain optimal engine temperature, which is vital for engine efficiency and longevity. Additionally, it may also be involved in other systems where fluid transfer is necessary, such as hydraulic systems or fuel lines 2.

Key Features of the 3911725 Molded Hose

The 3911725 boasts several key features that enhance its performance and durability. It is constructed from high-quality synthetic rubber, which provides resistance to heat, chemicals, and abrasion. The hose is reinforced with textile or wire spirals to maintain shape and prevent kinking under pressure. Its molded design ensures a precise fit within the truck’s systems, reducing the risk of leaks. Additionally, the hose is treated to resist ozone and weathering, extending its service life in various operating conditions 3.

Benefits of Using the 3911725 Molded Hose

Utilizing this Cummins part in commercial trucks offers several advantages. Its robust construction and precise fit contribute to improved system efficiency and reliability. The hose’s resistance to heat, chemicals, and abrasion ensures longevity, reducing the frequency of replacements and associated costs. Moreover, its role in maintaining optimal engine temperature enhances overall engine performance and fuel efficiency 4.

Installation Considerations

When installing the 3911725, it is important to follow Cummins’ guidelines to ensure proper fit and function. The hose should be inspected for any damage before installation, and the fitting surfaces should be clean and free of debris. It is recommended to use the appropriate clamps and tools to secure the hose in place, ensuring a leak-free connection. Following these best practices will help maintain the integrity of the fluid transfer system 5.

Troubleshooting Common Issues

Common issues with the 3911725 may include leaks, cracks, or blockages. If a leak is detected, the hose should be inspected for damage and replaced if necessary. Cracks may indicate exposure to excessive heat or abrasion, and the source of the damage should be addressed to prevent recurrence. Blockages can be caused by debris or sediment within the fluid, and the system should be flushed to remove any obstructions. Regular inspections can help identify and resolve these issues promptly.

Maintenance Tips

To ensure the longevity and optimal performance of the 3911725, regular maintenance is recommended. This includes periodic inspections for signs of wear, cracks, or leaks. The hose should be checked for proper clamping and connection integrity. Additionally, the fluid within the system should be kept clean and at the appropriate level to prevent contamination and ensure efficient operation. Following these maintenance tips will help extend the service life of the hose and maintain system reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various sectors, including transportation, construction, and agriculture. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Molded Hose Part 3911725 Compatibility

The Cummins molded hose part number 3911725 is a critical component designed to fit seamlessly with various Cummins engine models. This hose is engineered to meet the stringent requirements of high-performance engines, ensuring reliable operation and durability.

Engine Compatibility

- 4B3.9 Engines

- The molded hose part 3911725 is specifically designed to integrate with the 4B3.9 engine series. This engine is known for its robust construction and efficiency, making it a popular choice in various applications. The hose ensures that fluid pathways remain intact, preventing leaks and maintaining optimal engine performance.

Installation and Functionality

The molded hose part 3911725 is engineered to withstand the demanding conditions within the engine compartment. It is crafted from high-quality materials that resist wear and tear, ensuring longevity and consistent performance. The hose’s design allows for precise fitting, reducing the risk of misalignment and ensuring that all connections are secure.

Importance of Proper Fitment

Proper fitment of the molded hose is crucial for the engine’s overall health and efficiency. The hose must be correctly aligned and securely fastened to prevent any disruptions in fluid flow, which could lead to engine malfunctions. Regular inspections and timely replacement of the hose are recommended to maintain engine integrity and performance.

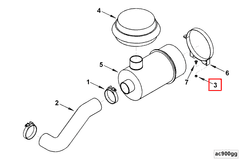

Role of Part 3911725 Molded Hose in Engine Systems

Part 3911725, a molded hose, is integral to the efficient operation of various engine systems. In the context of an air cleaner system, this hose facilitates the smooth transfer of air from the air cleaner to the engine’s intake manifold. It ensures that the air, once filtered of contaminants, reaches the engine in a controlled and uninterrupted flow. This is essential for maintaining the engine’s performance and fuel efficiency.

In addition to its role in the air cleaner system, the molded hose also plays a significant part in other engine-related systems. For instance, in systems where precise air-fuel mixture control is required, the hose ensures that the air supply is consistent and free from leaks, which could otherwise disrupt the mixture and lead to inefficient combustion.

Furthermore, the hose’s design allows it to withstand the high temperatures and pressures often encountered in engine compartments, making it a reliable component in ensuring the longevity and efficiency of the engine systems it serves.

Conclusion

The 3911725 Molded Hose is a vital component in the fluid transfer systems of commercial trucks, contributing to efficient and reliable operation. Its robust construction, precise fit, and resistance to various environmental factors make it a durable and dependable choice for maintaining engine performance and system integrity. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing Limited, 2011

↩ -

Generalized Vehicle Dynamics, Daniel Williams, SAE International, 2022

↩ -

Design of Racing and High-Performance Engines 2004-2013, Douglas R. Fehan, SAE International, 2013

↩ -

Fault Code Troubleshooting Manual, QSK60 CM2350 K149M, Bulletin Number 5659888

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.