This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

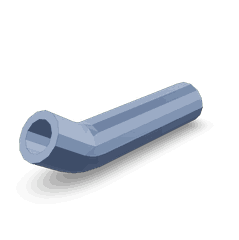

The 3970876 Molded Hose Assembly is a component manufactured by Cummins, a prominent name in the commercial truck industry. This hose assembly is designed for use in commercial trucks, where it plays a role in various systems. Cummins is known for producing reliable and high-quality parts that contribute to the efficient operation of heavy-duty vehicles.

Basic Concepts of Molded Hose Assembly

A Molded Hose Assembly is a pre-formed hose that is specifically designed to fit into a truck’s system without the need for additional fittings or connections. It is constructed from durable materials that can withstand the pressures and temperatures encountered in a truck’s engine compartment. The assembly functions by providing a secure and leak-free pathway for fluids such as coolant, oil, or air to travel between components within the truck’s system 1.

Purpose of the 3970876 Molded Hose Assembly

The 3970876 Molded Hose Assembly is integral to the operation of a truck, particularly in systems where fluid transfer is necessary. It supports various applications, including but not limited to, the cooling system, where it may transport coolant to and from the engine, or in the air intake system, where it could route air to the turbocharger. The assembly ensures that these systems operate efficiently by maintaining a consistent flow of the necessary fluids or gases 2.

Key Features

The 3970876 Molded Hose Assembly boasts several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, heat, and chemical exposure. The design of the assembly includes reinforced ends to prevent leaks and ensure a secure fit. Additionally, the hose may feature unique characteristics such as a spiral wire reinforcement for added strength or a smooth inner lining to reduce flow resistance 3.

Benefits

The advantages of using the 3970876 Molded Hose Assembly in truck operations include improved durability, which reduces the frequency of replacements and downtime. Its efficient design contributes to the overall performance of the truck’s systems, ensuring that fluids are transported without leaks or restrictions. The reliability of the assembly is also a significant benefit, as it is less prone to failure under the demanding conditions of commercial truck use 4.

Installation Process

Installing the 3970876 Molded Hose Assembly requires careful attention to detail to ensure a proper fit and function. The process involves disconnecting the old hose, if present, and connecting the new assembly to the appropriate fittings. Tools such as clamps and wrenches may be required to secure the connections. It is important to follow the manufacturer’s instructions to avoid damage to the assembly or the surrounding components 5.

Common Issues and Troubleshooting

Common problems with the 3970876 Molded Hose Assembly may include leaks, cracks, or detachment from fittings. Troubleshooting these issues involves inspecting the assembly for signs of wear or damage, ensuring that all connections are secure, and replacing the assembly if necessary. Regular checks can help identify potential issues before they lead to more significant problems 6.

Maintenance Tips

To ensure the longevity and optimal performance of the 3970876 Molded Hose Assembly, regular maintenance is recommended. This includes periodic inspections for wear or damage, checking connections for tightness, and replacing the assembly according to the manufacturer’s guidelines or when signs of degradation are observed. Keeping the assembly clean and free from debris can also contribute to its longevity 7.

Safety Considerations

When working with the 3970876 Molded Hose Assembly, it is important to observe safety guidelines to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring that the truck is turned off and cool before beginning work, and following all manufacturer-recommended procedures for installation and maintenance. Being aware of the potential hazards associated with the fluids the assembly transports is also crucial for safe operation 8.

Cummins Overview

Cummins is a company with a rich history in the commercial truck industry, known for its extensive product range and commitment to quality. The company has built a reputation for manufacturing reliable and efficient parts that contribute to the performance and durability of commercial vehicles. Cummins’ product lineup includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of the trucking industry 9.

Cummins Molded Hose Assembly Part 3970876

The Cummins Molded Hose Assembly part number 3970876 is a component in the engine systems of various Cummins engines. This part is designed to facilitate the transfer of fluids, gases, or other materials within the engine’s operational environment. Its robust construction ensures durability and reliability, making it a vital part of the engine’s overall performance.

Application in Cummins Engines

B4.5 Engine Series

The Cummins Molded Hose Assembly part 3970876 is specifically engineered to fit seamlessly into the B4.5 engine series. This engine series is known for its efficiency and reliability, often used in a variety of applications ranging from agricultural machinery to industrial equipment. The hose assembly plays a role in maintaining the fluid dynamics within the engine, ensuring that all necessary components receive the required fluids for optimal operation.

Other Cummins Engines

While the primary focus here is on the B4.5 engine series, it is important to note that the Cummins Molded Hose Assembly part 3970876 is also compatible with other Cummins engine models. This versatility makes it a valuable component for various engine types, ensuring that the hose assembly can be used across different platforms without compromising on performance or reliability.

The design and material of the hose assembly are tailored to withstand the harsh conditions typically found in engine environments. This includes exposure to high temperatures, pressure variations, and potentially corrosive substances. The use of high-quality materials ensures that the hose assembly maintains its integrity over time, contributing to the longevity and efficiency of the engine 10.

Role of Part 3970876 Molded Hose Assembly in Engine Systems

The 3970876 Molded Hose Assembly is a component in the efficient operation of engine systems, specifically in the management of the breather and crankcase ventilation systems.

Breather System Integration

In the breather system, the 3970876 Molded Hose Assembly facilitates the regulated flow of air and gases from the engine’s breather. This assembly connects the breather to the intake manifold or another suitable point in the intake system. By doing so, it ensures that any moisture, unburnt fuel, or other contaminants are effectively vented from the engine, maintaining optimal air-fuel ratios and preventing the accumulation of harmful deposits.

Crankcase Ventilation System

For the crankcase ventilation system, the 3970876 Molded Hose Assembly plays a role in managing the pressure within the crankcase. It connects the crankcase to the intake tract, allowing the safe and efficient venting of gases produced during combustion. This process helps in reducing the build-up of pressure, which can lead to oil leaks and other engine complications. Additionally, it aids in the removal of blow-by gases, which are a mixture of combustion gases, unburnt fuel, and moisture that escape past the piston rings into the crankcase.

Overall System Efficiency

The effective integration of the 3970876 Molded Hose Assembly in these systems contributes to the overall efficiency and longevity of the engine. It ensures that the engine operates within its designed parameters, reducing wear and tear on critical components and enhancing performance. The assembly’s durable construction and precise fitment are essential in withstanding the varying pressures and temperatures within the engine compartment, providing a reliable solution for ventilation needs 11.

Conclusion

The 3970876 Molded Hose Assembly by Cummins is a critical component for the efficient operation of commercial truck engines. Its robust design, compatibility with various engine models, and role in maintaining system efficiency make it an indispensable part of the engine’s operation. Regular maintenance and adherence to safety guidelines are essential to ensure the longevity and reliability of this Cummins part.

-

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Cummins Inc. (n.d.). Service Manual (5411050). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5411050). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5411050). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5411050). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5411050). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5411050). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5411050). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5411050). Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.