This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

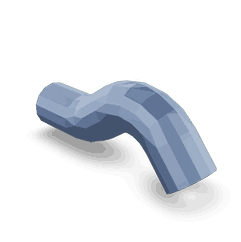

The Cummins 3977561 Molded Hose is a specialized component designed for use in commercial trucks. It serves a significant role in ensuring the efficient operation of various truck systems by facilitating the transfer of fluids. Understanding its purpose and functionality is key to maintaining the overall performance and reliability of commercial vehicles.

Basic Concepts of Molded Hoses

Molded hoses are engineered components used extensively in automotive and industrial applications. They are constructed by molding synthetic rubber or other durable materials around embedded textile or wire reinforcements. This construction method provides molded hoses with the flexibility and strength required to withstand high pressure and temperature variations. In automotive systems, molded hoses are commonly used to transport fluids such as coolant, fuel, and hydraulic fluid, connecting various components within the system 1.

Purpose of the 3977561 Molded Hose

This Cummins part is specifically designed to connect critical components within a truck’s system, facilitating the transport of fluids essential for the vehicle’s operation. It plays a role in ensuring the smooth flow of fluids between parts, contributing to the efficient functioning of the truck. The hose is integral to maintaining system integrity by providing a reliable connection that can endure the rigors of commercial use.

Key Features

The design and construction of the 3977561 Molded Hose incorporate several features that enhance its performance and durability. It is made from high-quality materials that offer resistance to wear, tear, and environmental factors. The hose features secure connection types that ensure a tight fit with compatible components, reducing the risk of leaks. Additionally, its construction includes reinforcements that provide structural integrity under pressure, contributing to its longevity in demanding conditions.

Benefits

This part offers several advantages that contribute to its reputation for reliability and performance. Its robust construction ensures improved resistance to wear and tear, reducing the likelihood of failures. The hose’s design allows for enhanced performance in challenging conditions, making it suitable for the demanding environments encountered by commercial trucks. These benefits contribute to the overall efficiency and reliability of the vehicle.

Installation Considerations

When installing the 3977561 Molded Hose, it is important to follow guidelines and best practices to ensure compatibility with other components and optimal performance. The installation process may require specific tools and procedures to achieve a secure and leak-free connection. Careful attention to detail during installation can prevent common issues and ensure the hose functions as intended within the truck’s system.

Troubleshooting Common Issues

Common problems that may arise with this Cummins part include leaks or blockages. These issues can often be diagnosed through visual inspection and testing of the system. Addressing these problems promptly can prevent more significant issues and maintain the efficiency of the truck’s operation. Suggested methods for resolution may include repairing or replacing the hose, depending on the severity of the issue.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 3977561 Molded Hose. Inspection intervals should be established to check for signs of wear, damage, or leaks. Care procedures may include cleaning the hose and its connections, as well as applying protective coatings if necessary. Adhering to these maintenance tips can help prevent unexpected failures and extend the service life of the hose.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range is designed to meet the demanding requirements of commercial applications, ensuring reliability and performance in various operating conditions 2.

Cummins Molded Hose Part 3977561 Compatibility

The Cummins molded hose part number 3977561 is designed to fit seamlessly within the engine systems of the QSB5.9 CM850 and QSB6.7 M CM2250 engines. This hose is engineered to ensure optimal performance and durability, providing a reliable connection for various fluid transfer applications within these engines.

In the QSB5.9 CM850 engine, the molded hose part 3977561 is specifically tailored to integrate with the engine’s hydraulic and cooling systems. Its robust construction and precise fitment ensure that it can withstand the operational stresses and temperatures inherent in these systems, thereby maintaining the engine’s efficiency and longevity.

Similarly, for the QSB6.7 M CM2250 engine, this molded hose is critical in connecting various fluid lines, ensuring that the engine’s hydraulic and cooling systems function smoothly. The part’s design accommodates the unique layout and requirements of the QSB6.7 M CM2250, providing a secure and leak-proof connection that is essential for the engine’s overall performance.

Both engines benefit from the use of this molded hose, as it is crafted to meet Cummins’ stringent quality standards, ensuring that it performs reliably under demanding conditions. The hose’s compatibility with these engines underscores Cummins’ commitment to providing high-quality, durable parts that enhance engine performance and reliability.

Role of Part 3977561 Molded Hose in Engine Systems

Part 3977561, a Molded Hose, is integral to the efficient operation of various engine systems. It facilitates the secure and reliable transfer of fluids and gases between different components, ensuring optimal performance and safety.

Connection

The Molded Hose serves as a vital link in the connection between various engine components. It allows for the smooth and uninterrupted flow of fluids, such as coolant or oil, between the engine block and the radiator. This connection is essential for maintaining the engine’s temperature within safe operating limits, preventing overheating and potential damage.

Exhaust Outlet

In exhaust systems, the Molded Hose plays a significant role in connecting the exhaust manifold to the catalytic converter or the exhaust outlet. This connection ensures that exhaust gases are efficiently directed away from the engine, reducing emissions and enhancing overall engine performance. The hose’s durable construction withstands high temperatures and pressures, ensuring a secure and long-lasting connection.

Plumbing

Within the engine’s plumbing system, the Molded Hose is used to connect various fluid lines, including those for fuel, brake fluid, and power steering. These connections are designed to handle the specific pressures and temperatures associated with each fluid, ensuring reliable operation and preventing leaks. The hose’s flexibility allows it to accommodate the movement and vibrations inherent in engine operation, maintaining a secure fit over time.

Exhaust Outlet Connection

The Molded Hose is also employed in the exhaust outlet connection, where it links the exhaust pipe to the muffler or tailpipe. This connection is crucial for maintaining the integrity of the exhaust system, ensuring that gases are expelled efficiently and quietly. The hose’s resistance to corrosion and degradation under extreme conditions makes it an ideal choice for this application, contributing to the overall durability and performance of the exhaust system 3.

Conclusion

The Cummins 3977561 Molded Hose is a critical component in the efficient operation of commercial truck engine systems. Its robust design, compatibility with specific engine models, and role in fluid transfer applications highlight its importance in maintaining vehicle performance and reliability. Regular maintenance and proper installation are essential to ensure the longevity and effectiveness of this part in demanding commercial environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.