This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

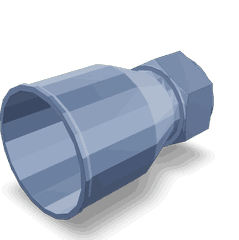

The 3069174 Plain Hose Coupling is a component manufactured by Cummins, a well-established name in the commercial truck industry. This hose coupling is designed for use in commercial trucks, where it facilitates the connection of various fluid transfer systems. Understanding its role, features, and benefits can help ensure optimal performance and longevity of the truck’s systems.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are devices used to connect hoses in fluid transfer systems. They allow for the quick and secure connection and disconnection of hoses without the need for additional tools. These couplings are commonly used in applications where flexibility, ease of use, and reliability are paramount. They function by creating a seal between the hose and the coupling, which prevents leaks and ensures the efficient transfer of fluids 1.

Purpose of the 3069174 Plain Hose Coupling

The 3069174 Plain Hose Coupling by Cummins is specifically designed to connect hoses in commercial truck systems. It plays a role in various fluid transfer applications, including but not limited to, coolant, fuel, and hydraulic systems. By providing a secure connection, it ensures that fluids are transferred efficiently and without leakage, which is vital for the proper operation of the truck 2.

Key Features

The 3069174 Plain Hose Coupling boasts several key features that enhance its performance. It is constructed from durable materials that can withstand the rigors of commercial truck environments. The design includes elements that ensure a tight seal, reducing the risk of leaks. Additionally, it is engineered for easy installation and removal, which can save time during maintenance procedures 3.

Benefits

Using the 3069174 Plain Hose Coupling offers several advantages. Its durable construction contributes to a longer service life, reducing the frequency of replacements. The ease of installation and removal not only saves time but also minimizes the potential for installation errors. Furthermore, its design helps to prevent leaks, which can lead to system inefficiencies or damage.

Installation Process

Installing the 3069174 Plain Hose Coupling involves several steps to ensure a secure fit. First, the hose should be prepared by ensuring it is clean and free of any debris. The coupling is then aligned with the hose end and pushed on until a secure connection is achieved. It is important to follow the manufacturer’s guidelines to ensure proper installation.

Troubleshooting Common Issues

Common issues with plain hose couplings may include leaks or disconnections. These can often be addressed by inspecting the coupling for signs of wear or damage, ensuring that it is properly installed, and checking that the hose is compatible with the coupling. Regular maintenance can help prevent these issues from occurring.

Maintenance Tips

To prolong the life of the 3069174 Plain Hose Coupling, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the coupling to remove any buildup, and ensuring that all connections are secure. Following these practices can help maintain the efficiency and reliability of the truck’s fluid transfer systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence make it a trusted partner for commercial truck operators worldwide.

Engine Compatibility with Cummins Part 3069174

The Cummins part 3069174, a Plain Hose Coupling, is designed to fit seamlessly with various engine models. This part is integral to ensuring proper fluid and air flow within the engine systems, maintaining the overall efficiency and performance of the engines.

Cummins Powertrain Engines

- 6C8.3: This engine benefits from the precise fit of the Plain Hose Coupling, ensuring optimal fluid transfer and reducing the risk of leaks.

- ISX CM570: The Plain Hose Coupling is essential for maintaining the integrity of the fluid lines in this high-performance engine.

- K19: This engine model utilizes the Plain Hose Coupling to ensure reliable connections in its complex system.

- K38: The Plain Hose Coupling is a critical component for the K38, providing a secure and leak-proof connection.

- K50: Ensuring the K50 operates smoothly, the Plain Hose Coupling is designed to fit perfectly with this engine’s specifications.

Cummins Medium-Duty Engines

- M11 MECHANICAL: The Plain Hose Coupling is a key component for the M11 MECHANICAL, ensuring that all fluid lines are securely connected.

- N14 CELECT: This engine model relies on the Plain Hose Coupling to maintain fluid integrity and prevent leaks.

- N14 CELECT PLUS: The N14 CELECT PLUS engine benefits from the precise fit of the Plain Hose Coupling, ensuring reliable performance.

- N14 G: The Plain Hose Coupling is essential for the N14 G, providing a secure connection for fluid lines.

- N14 MECHANICAL: Ensuring the N14 MECHANICAL operates smoothly, the Plain Hose Coupling is designed to fit perfectly with this engine’s specifications.

Cummins Medium-Duty and Heavy-Duty Engines

- NH/NT 855: The Plain Hose Coupling is a critical component for the NH/NT 855, providing a secure and leak-proof connection.

- QSK19 CM500: This engine model utilizes the Plain Hose Coupling to ensure reliable connections in its complex system.

- QSK19 CM850 MCRS: The Plain Hose Coupling is essential for the QSK19 CM850 MCRS, ensuring optimal fluid transfer and reducing the risk of leaks.

- QSM11 CM570: The Plain Hose Coupling is a key component for the QSM11 CM570, ensuring that all fluid lines are securely connected.

- QSN14 CM876 N103: The Plain Hose Coupling is essential for the QSN14 CM876 N103, ensuring reliable performance.

Cummins Industrial Engines

- V28: The Plain Hose Coupling is a critical component for the V28, providing a secure and leak-proof connection.

- V903: This engine model relies on the Plain Hose Coupling to maintain fluid integrity and prevent leaks.

- VTA903 CM2250 V105: The Plain Hose Coupling is essential for the VTA903 CM2250 V105, ensuring optimal fluid transfer and reducing the risk of leaks.

Role of Part 3069174 Plain Hose Coupling in Engine Systems

The Part 3069174 Plain Hose Coupling is instrumental in ensuring the seamless integration and operation of various engine components. It facilitates the connection between different hoses and plumbing systems, enhancing the overall efficiency and reliability of the engine.

Integration with Engine Components

-

Accessories G.T Starting: The Plain Hose Coupling is used to connect hoses associated with the starting accessories, ensuring a secure and leak-free connection that supports the starting process.

-

Auxiliary Hoses: It plays a key role in linking auxiliary hoses, which are essential for various engine functions, including coolant circulation and fuel delivery.

-

Coolant Heater Plumbing: In coolant heater systems, the coupling ensures that the hoses are properly connected, allowing for efficient heating and circulation of coolant to prevent engine freeze-up in cold conditions.

-

Float Tank: The coupling is utilized in the plumbing associated with the float tank, ensuring that fuel is accurately measured and delivered to the engine.

-

Fuel Filter/Water Separator: It connects the hoses leading to and from the fuel filter and water separator, maintaining a consistent fuel flow and preventing contamination.

-

Fuel Hose: The Plain Hose Coupling is essential for connecting fuel hoses, ensuring a secure and reliable fuel supply to the engine.

-

Fuel Transfer Tank: It facilitates the connection of hoses in the fuel transfer system, allowing for the safe and efficient transfer of fuel between tanks.

-

Governor, Electronic: In electronic governor systems, the coupling ensures that hoses are properly connected for accurate fuel and air mixture control.

-

Hose Spares Kit: The coupling is a vital component in hose spares kits, providing a reliable connection for replacement hoses during maintenance.

-

Injector: It connects hoses associated with the injector system, ensuring precise fuel delivery to the combustion chamber.

-

Kit: Various engine kits utilize the Plain Hose Coupling to ensure all hoses are securely connected, supporting the kit’s intended function.

-

On Board Spares: The coupling is used in on-board spares to quickly and effectively connect replacement hoses during repairs.

-

MTG, AMOT Safety Control: In safety control systems, the coupling ensures that hoses are securely connected, maintaining the integrity of the safety mechanisms.

-

Oil Control Valve: It connects hoses to the oil control valve, ensuring proper oil flow and pressure regulation within the engine.

-

Oil Control Valve Mounting Plumbing: The coupling is used in the plumbing associated with the oil control valve mounting, ensuring a stable and leak-free connection.

-

Parts Tachometer: In tachometer systems, the coupling connects hoses that may be part of the sensor or fluid delivery systems.

-

Plumbing, Fuel Transfer Pump: It ensures that hoses connected to the fuel transfer pump are securely linked, facilitating efficient fuel transfer.

-

Plumbing Step: The coupling is used in step plumbing to connect hoses at various stages, ensuring a consistent flow of fluids.

-

Prelube Starter: In prelube starter systems, the coupling connects hoses that deliver lubricant to critical engine components before startup.

-

Primer, Fuel System: It ensures that hoses in the primer and fuel system are properly connected, allowing for effective priming and fuel delivery.

-

Primer Mounting: The coupling is used in primer mounting systems to connect hoses, ensuring a secure and reliable priming process.

-

Step Hoses Kit: In step hoses kits, the coupling provides a reliable connection for hoses at different stages of the system.

-

Step Mounting Plumbing: It ensures that hoses in step mounting plumbing are securely connected, supporting the step-by-step fluid flow.

-

Step Plumbing and Mounting: The coupling is essential for connecting hoses in step plumbing and mounting systems, ensuring a consistent and reliable fluid pathway.

-

Tachometer Parts Kit: In tachometer parts kits, the coupling connects hoses that may be part of the sensor or fluid delivery systems.

-

Water Cooling Hoses: Finally, the Plain Hose Coupling is used in water cooling systems to connect hoses, ensuring efficient coolant flow and engine temperature regulation.

Conclusion

The 3069174 Plain Hose Coupling by Cummins is a vital component in the fluid transfer systems of commercial trucks. Its durable construction, ease of installation, and reliable performance make it an essential part for maintaining the efficiency and reliability of truck engines. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Tom Denton and Hayley Pells, Automotive Technician Training Theory, Routledge, 2022.

↩ -

Willard W. Pulkrabek, Engineering Fundamentals of the Internal Combustion Engine, Pearson Education, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.