This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

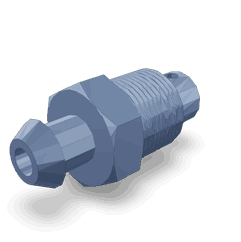

The Cummins 3282720 Plain Hose Coupling is a component designed for use in commercial truck systems. It serves to connect hoses securely, facilitating the transfer of fluids such as coolant, fuel, or hydraulic fluid within the truck’s systems. This coupling ensures that connections are both efficient and reliable, contributing to the overall performance and safety of the vehicle.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are devices used to join two hoses or a hose to a fitting without the need for clamps or additional fasteners. They operate by compressing the hose between two flanges, creating a seal that allows for fluid transfer. These couplings are commonly used in various fluid transfer systems across different industries due to their simplicity and effectiveness in providing secure connections 1.

Purpose and Role in Truck Operation

In the context of commercial trucks, the Cummins 3282720 Plain Hose Coupling plays a significant role in ensuring that fluid systems operate efficiently. It provides a secure connection point for hoses, which is vital for maintaining the integrity of fluid transfer pathways. This ensures that fluids are delivered consistently and without leaks, which is crucial for the proper functioning of engine cooling, fuel delivery, and hydraulic systems 2.

Key Features

The Cummins 3282720 Plain Hose Coupling is characterized by several key features that enhance its performance and durability. It is designed with precision-machined flanges that ensure a tight seal, reducing the risk of leaks. The coupling is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. Additionally, its design allows for easy installation and removal, facilitating maintenance and repair processes 3.

Benefits

The Cummins 3282720 Plain Hose Coupling offers several benefits that make it a valuable component in commercial truck systems. Its design contributes to improved reliability by providing a secure connection that minimizes the risk of fluid leaks. The ease of installation reduces downtime during maintenance, and its durable construction means fewer replacements are needed over time. Furthermore, the coupling’s design allows for quick disconnection and reconnection, which is beneficial during routine checks or emergency repairs.

Installation Process

Installing the Cummins 3282720 Plain Hose Coupling involves several steps to ensure a proper and secure connection. First, the hoses to be connected should be cleaned and inspected for any damage. The coupling is then positioned over one end of the hose, and the other hose is inserted into the opposite side. A tool, such as a hose clamp plier, may be used to tighten the coupling, ensuring that the hoses are compressed evenly between the flanges. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the hose or coupling.

Troubleshooting Common Issues

Common issues with plain hose couplings include leaks, difficulty in disconnection, and hose damage. Leaks may occur due to improper installation, hose degradation, or insufficient compression. To address leaks, inspect the connection for proper alignment and compression. If the hose is damaged, it should be replaced. Difficulty in disconnection may be resolved by using the appropriate tool to loosen the coupling gradually. Regular inspection and maintenance can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3282720 Plain Hose Coupling, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the coupling and hoses can prevent buildup that may affect performance. Additionally, ensuring that the coupling is properly tightened according to manufacturer specifications during installation will help maintain a secure connection.

Safety Considerations

When working with plain hose couplings, it is important to observe safety guidelines to prevent accidents. Ensure that the system is depressurized before attempting any maintenance or repair. Use the appropriate tools for installation and removal to avoid injury or damage to the components. Wear protective equipment, such as gloves and safety glasses, to protect against fluid spills or debris.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a pioneer in the diesel engine industry, committed to innovation and sustainability. The company’s expertise in engine manufacturing and its dedication to advancing technology have made it a trusted name in the automotive and heavy-duty truck sectors.

Application in Engine Models

-

6B5.9 Series: The 3282720 Plain Hose Coupling is integral to the 6B5.9 engine series, where it is used in both the cooling and exhaust systems. Its primary role is to connect hoses to various engine components, ensuring that coolant and exhaust gases are managed efficiently. This coupling’s design allows it to withstand the high temperatures and pressures typical in engine environments, ensuring durability and reliability.

-

Group Usage: In broader engine groups, the 3282720 Plain Hose Coupling is utilized in engines that require robust connections for fluid and gas transfer. Its application extends to various engine configurations, making it a versatile component in Cummins’ engine lineup. The part’s design ensures that it fits seamlessly into the engine’s architecture, providing a reliable connection point for hoses.

Importance in Engine Performance

The Plain Hose Coupling part number 3282720 plays a vital role in maintaining engine performance by ensuring that hoses remain securely attached to engine components. This is crucial for preventing leaks, which can lead to system inefficiencies and potential engine damage. By providing a secure and leak-proof connection, this coupling helps maintain the integrity of the engine’s cooling and exhaust systems, contributing to overall engine reliability and longevity.

Installation and Maintenance

Proper installation of the 3282720 Plain Hose Coupling is essential to ensure its effectiveness. Technicians should follow the manufacturer’s guidelines for installation, ensuring that the coupling is correctly aligned and tightened to the specified torque. Regular maintenance checks should be performed to inspect the coupling for signs of wear or damage, ensuring that it continues to provide a secure connection throughout the engine’s operational life.

Integration with Fuel Filter

The Plain Hose Coupling facilitates the connection between the fuel filter and the fuel lines. This ensures that fuel is efficiently filtered before it reaches the engine, maintaining the quality of fuel that the engine consumes. The coupling’s design allows for easy installation and removal, which is beneficial during maintenance or replacement of the fuel filter.

Fuel Line Connectivity

In the fuel delivery system, the Plain Hose Coupling plays a key role in connecting different sections of the fuel lines. This connection is vital for maintaining a consistent fuel flow from the tank to the engine. The coupling’s robust construction ensures that it can withstand the pressure and vibrations inherent in the fuel system, providing a reliable connection point.

Plumbing System Integration

The coupling is also used within the engine’s plumbing system to connect various fluid lines, such as coolant or hydraulic lines. Its application in these systems ensures that fluids are transferred efficiently and without leaks, contributing to the overall reliability and performance of the engine.

Overall System Efficiency

By providing secure and leak-proof connections, the 3282720 Plain Hose Coupling enhances the efficiency and reliability of the engine’s fluid systems. Its role in connecting critical components like the fuel filter and fuel lines underscores its importance in maintaining the engine’s optimal performance.

Conclusion

The Cummins 3282720 Plain Hose Coupling is a critical component in both commercial truck systems and engine models, ensuring secure and efficient fluid transfer. Its design, characterized by precision-machined flanges and high-quality materials, contributes to the reliability and longevity of the systems it serves. Proper installation, regular maintenance, and adherence to safety guidelines are essential to maximize the benefits of this part, ultimately contributing to the overall performance and safety of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.