This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

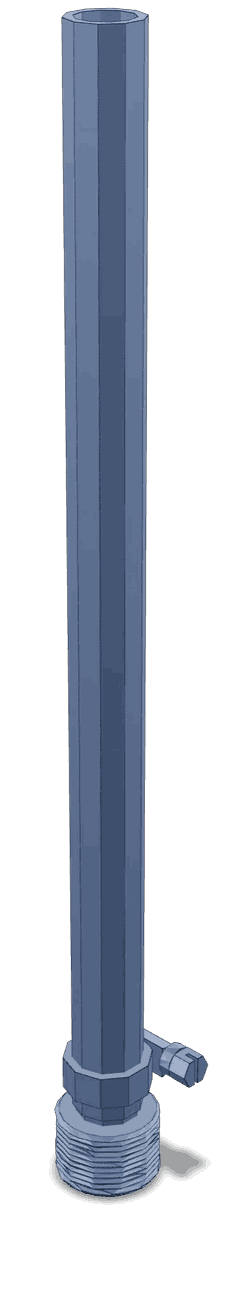

The 3282945 Plain Hose Connector, manufactured by Cummins, is a component designed for use in commercial trucks. It facilitates the secure connection of hoses within various fluid systems, ensuring efficient and leak-free operation.

Basic Concepts of Plain Hose Connectors

Plain hose connectors are devices that join hoses in fluid systems, ensuring a leak-free connection by clamping the hose ends together. In trucks, these connectors are integral to the functionality of systems such as the fuel, coolant, and hydraulic systems 1.

Purpose of the 3282945 Plain Hose Connector

The 3282945 Plain Hose Connector connects hoses in systems that require fluid transfer. It is commonly used in applications where fluids need to be transported efficiently and securely, such as in the fuel delivery system or coolant circulation. The connector ensures that the hoses remain attached under various operating conditions, contributing to the overall reliability of the truck’s fluid systems 2.

Key Features

This Cummins part is constructed with materials that offer durability and resistance to the fluids it handles. It features a design that allows for easy connection and disconnection of hoses, which is beneficial during maintenance or repairs. The connector may include specific attributes such as a corrosion-resistant coating or a design that reduces the risk of hose disconnection under vibration, enhancing its functionality in a truck’s demanding environment 3.

Benefits

Using the 3282945 Plain Hose Connector provides several advantages. It offers improved reliability in fluid system connections, which is vital for the consistent operation of a truck. The design of the connector also facilitates ease of installation, reducing downtime during maintenance. Additionally, its construction allows for straightforward maintenance, which can help in prolonging the service life of the connected hoses and the overall system.

Installation Process

To install the 3282945 Plain Hose Connector, one should follow a series of steps to ensure a secure fit. This includes preparing the hose ends for connection, aligning the connector with the hoses, and tightening the clamp to the manufacturer’s specifications. Tools such as wrenches may be required, and it is important to follow best practices to avoid over-tightening, which could damage the hose or the connector.

Troubleshooting Common Issues

Common issues with plain hose connectors may include leaks or disconnections. To address these, one should first inspect the connector and hoses for signs of wear or damage. Ensuring that the connector is properly tightened and that the hoses are in good condition can often resolve these issues. If problems persist, replacement of the connector or hoses may be necessary.

Maintenance Tips

Regular maintenance of the 3282945 Plain Hose Connector involves inspection for signs of wear, corrosion, or leaks. Cleaning the connector and ensuring that all connections are tight can help prevent issues. It is also important to replace the connector if it shows signs of significant wear or if it has been involved in a leak, to maintain the integrity of the fluid system.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all of which are designed to meet the demanding requirements of commercial vehicles.

Cummins Engine Part 3282945: Plain Hose Connector Compatibility

The Cummins part 3282945, a Plain Hose Connector, is designed to fit seamlessly with a variety of Cummins engines. This part is integral in ensuring the proper routing and connection of hoses within the engine system, facilitating efficient fluid transfer and maintaining the integrity of the engine’s cooling and fuel systems.

Engine Compatibility

-

4B3.9, 6B5.9, 6C8.3, B4.5, QSB3.9 30 CM550

The Plain Hose Connector 3282945 is compatible with these engines, providing a reliable connection point for various hoses. This ensures that the fluid pathways remain unobstructed, which is crucial for maintaining engine performance and longevity.

-

QSB4.5 CM2250 EC, QSB4.5 CM850 (CM2850)

These engines also benefit from the use of part 3282945. The connector’s design allows for precise and secure hose attachment, which is essential for the efficient operation of the engine’s cooling and fuel systems.

-

QSB5.9 30 CM550, QSB6.7 CM850 (CM2850)

The Plain Hose Connector is equally important for these engines. Its robust construction and precise fit ensure that the hoses remain securely connected, preventing leaks and maintaining system efficiency.

-

QSB7 CM2880 B117

Finally, the QSB7 CM2880 B117 engine is also compatible with part 3282945. This connector plays a vital role in the engine’s overall functionality by ensuring that all necessary hoses are properly connected and secured.

By ensuring a secure and reliable connection, the Plain Hose Connector 3282945 contributes to the overall efficiency and reliability of these Cummins engines.

Role of Part 3282945 Plain Hose Connector in Engine Systems

The Part 3282945 Plain Hose Connector is integral to the fluid management within various engine systems. It facilitates the secure connection between hoses and other components, ensuring efficient fluid transfer and system integrity.

Integration with Engine Components

-

Drain Systems: In drain systems, the Plain Hose Connector is used to link the drain hose to the engine block or sump. This connection allows for the controlled release of fluids, such as coolant or oil, during maintenance procedures. The secure fit provided by the connector prevents leaks, ensuring that the draining process is clean and efficient.

-

Remote Oil Systems: For engines equipped with remote oil systems, the Plain Hose Connector plays a key role in connecting the oil lines to the remote oil pan. This setup is common in high-performance or custom engine builds where the oil pan is located away from the engine block. The connector ensures a tight seal, maintaining oil pressure and flow integrity throughout the system.

-

Oil Pans: When dealing with oil pans, especially in aftermarket or custom installations, the Plain Hose Connector is used to attach oil return lines or breather hoses. This connection is vital for maintaining the oil level and pressure within the pan, as well as for venting any excess pressure or contaminants.

-

Oil Systems: In standard oil systems, the Plain Hose Connector is often employed to join various oil lines, such as those leading to and from the oil filter, oil cooler, or pressure relief valve. This ensures a consistent oil flow, which is essential for engine lubrication and cooling.

By providing a reliable and leak-free connection, the Part 3282945 Plain Hose Connector contributes to the overall efficiency and safety of engine fluid systems. Its application across different components underscores its versatility and importance in maintaining optimal engine performance.

Conclusion

The 3282945 Plain Hose Connector is a critical component in the fluid systems of commercial trucks, ensuring secure and efficient connections between hoses. Its compatibility with various Cummins engines, coupled with its robust design and ease of maintenance, makes it an essential part for maintaining the reliability and performance of truck fluid systems.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.