This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

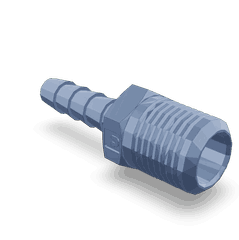

The 3920191 Straight Hose Coupling, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces this coupling to facilitate efficient fluid transfer within various truck systems. The 3920191 Straight Hose Coupling is integral to maintaining the operational integrity of hydraulic and fuel systems in commercial trucks.

Basic Concepts of Straight Hose Couplings

Straight hose couplings are devices used to connect two hoses or a hose to a fitting in fluid transfer systems. They allow for the seamless transfer of fluids such as hydraulic oil or fuel, ensuring that systems operate without interruption. In the context of a truck’s hydraulic or fuel system, these couplings enable the connection between different components, facilitating the movement of fluids necessary for the truck’s operation.

Purpose of the 3920191 Straight Hose Coupling

The 3920191 Straight Hose Coupling is specifically designed to play a role in the fluid transfer systems of commercial trucks. It is applied in hydraulic systems to connect hoses that transport hydraulic fluid, which is crucial for operating various truck mechanisms. Additionally, it may be used in fuel systems to ensure a secure connection between fuel lines, contributing to the efficient delivery of fuel to the engine.

Key Features

The 3920191 Straight Hose Coupling boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The design includes precise fitting mechanisms that provide a secure connection, minimizing the risk of leaks. Additionally, it features easy-to-use clamps that simplify the installation process.

Benefits

The 3920191 Straight Hose Coupling offers several benefits that contribute to its effectiveness in commercial truck operations. It provides improved fluid transfer efficiency, ensuring that hydraulic and fuel systems operate smoothly. Its durable construction leads to a longer service life, reducing the need for frequent replacements. The ease of installation further adds to its appeal, allowing for quick maintenance and repairs.

Installation Process

Installing the 3920191 Straight Hose Coupling involves several steps to ensure a secure and effective connection. Begin by preparing the hose ends, ensuring they are clean and free from debris. Slide the coupling onto one hose end, then connect the second hose, ensuring a snug fit. Use the provided clamps to secure the connection, tightening them to the manufacturer’s specifications. Finally, inspect the connection for any signs of leaks before operating the system.

Troubleshooting Common Issues

Common issues with straight hose couplings include leaks and disconnections. To troubleshoot these problems, first, inspect the coupling for signs of wear or damage. Check the clamps to ensure they are tightened correctly. If a leak is present, disassemble the coupling, clean the hose ends, and reassemble, ensuring a proper fit. Regular inspections can help identify potential issues before they lead to system failures.

Maintenance Tips

To ensure the longevity and reliable performance of the 3920191 Straight Hose Coupling, regular maintenance is recommended. Inspect the coupling at regular intervals for signs of wear, corrosion, or leaks. Clean the coupling and hose ends as needed to remove any buildup that could affect performance. If significant wear is observed, consider replacing the coupling to prevent system failures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and components, all designed to meet the demanding requirements of commercial vehicle operations. The 3920191 Straight Hose Coupling is a testament to Cummins’ commitment to providing high-quality, reliable components for the industry.

Compatibility of Straight Hose Coupling Part 3920191 with Cummins Engines

The Straight Hose Coupling part number 3920191, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is essential for ensuring proper fluid transfer and maintaining system integrity across different engine models. Below is a detailed overview of the engines with which this coupling is compatible:

Cummins 4B3.9 and 6B5.9 Engines

The Straight Hose Coupling part 3920191 is compatible with the Cummins 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in various industrial and agricultural applications. The coupling ensures that the fluid pathways remain secure and efficient, contributing to the overall operational efficiency of these engines.

Cummins 6C8.3 and C8.3 G Engines

The part 3920191 also fits the Cummins 6C8.3 and C8.3 G engines. These engines are part of the Cummins C Series, which is recognized for its versatility and power. The coupling’s design allows for seamless integration with these engines, ensuring that the fluid systems operate without leaks or disruptions.

Cummins G8.3 and C GAS PLUS CM556 Engines

The Straight Hose Coupling part 3920191 is compatible with the Cummins G8.3 and C GAS PLUS CM556 engines. These engines are often used in heavy-duty applications, requiring reliable and durable components. The coupling’s precision fit ensures that the fluid systems remain intact, supporting the engines’ performance and longevity.

Cummins ISB Series Engines

The part 3920191 is also suitable for several models within the Cummins ISB series, including:

- ISB CM2150

- ISB CM550

- ISB5.9G CM2180

- ISB6.7 CM2250

- ISB6.7 G CM2180 B118

- ISL G CM2180

- ISX CM570

- ISX CM870

- ISX12 G CM2180 EJ

These engines are widely used in various sectors, including transportation, construction, and power generation. The coupling’s compatibility with these engines ensures that the fluid systems are well-maintained, contributing to the overall efficiency and reliability of the ISB series engines.

Cummins QSB Series Engines

The Straight Hose Coupling part 3920191 fits the Cummins QSB4.5 CM850 (CM2850) and QSB6.7 M CM2250 engines. These engines are known for their durability and performance in demanding environments. The coupling’s design ensures that the fluid systems remain secure and efficient, supporting the engines’ operational needs.

By ensuring compatibility with these diverse engine models, the Straight Hose Coupling part 3920191 plays a crucial role in maintaining the integrity and performance of Cummins engines across various applications.

Role of Part 3920191 Straight Hose Coupling in Engine Systems

The Part 3920191 Straight Hose Coupling is instrumental in ensuring the seamless connection and efficient operation of various components within engine systems. Its application spans across multiple subsystems, enhancing the overall performance and reliability of the engine.

Air Connection and Turbocharger System

In the turbocharger system, the straight hose coupling is used to connect the air intake to the turbocharger. This ensures a secure and leak-free connection, allowing for optimal airflow into the engine. The coupling’s design minimizes pressure loss, which is essential for maintaining turbocharger efficiency and engine performance.

Engine Cooling System

Within the engine cooling system, the straight hose coupling plays a significant role in connecting the radiator to the engine block and thermostat housing. This connection facilitates the smooth circulation of coolant, ensuring that the engine maintains an optimal operating temperature. The coupling’s robust construction withstands the high temperatures and pressures within the cooling system, contributing to the longevity of the engine.

Fuel System

In the fuel system, the straight hose coupling is employed to connect the fuel control module to the fuel pressure regulator and other components. This ensures a consistent fuel supply to the engine, which is vital for combustion efficiency and power output. The coupling’s precise fit prevents fuel leaks, enhancing safety and performance.

Crankcase Ventilation

The straight hose coupling is also utilized in the crankcase ventilation system, connecting the breather to the crankcase. This connection allows for the efficient removal of gases and moisture from the crankcase, preventing buildup that could lead to engine damage. The coupling ensures a secure seal, maintaining the integrity of the ventilation system.

Aftercooler Water Plumbing

In systems with an aftercooler, the straight hose coupling is used to connect the aftercooler water plumbing. This connection ensures that the aftercooler receives a consistent water supply, which is essential for cooling the compressed air before it enters the engine. The coupling’s design facilitates efficient water flow, enhancing the aftercooler’s performance and the engine’s overall efficiency.

Deaerator Connection

The straight hose coupling is also integral in the deaerator connection within the engine system. It ensures that the deaerator effectively removes air and gases from the coolant, preventing cavitation and corrosion within the engine. The coupling’s reliable connection is key to maintaining the deaerator’s efficiency and the engine’s health.

Campaign Kit and Control Valve Body

In campaign kits and control valve bodies, the straight hose coupling is used to connect various components, ensuring that the system operates as intended. Whether it’s connecting the control valve body to the plumbing or integrating components within the campaign kit, the coupling’s role is essential for the system’s functionality and performance.

Vent and Pressure Regulator Valve

The straight hose coupling is also employed in connecting the vent to the engine system and the pressure regulator valve to its respective components. These connections are vital for maintaining system pressure and preventing issues such as over-pressurization, which could lead to component failure.

Conclusion

In summary, the Part 3920191 Straight Hose Coupling is a versatile component that enhances the connectivity and efficiency of various engine systems. Its application across different subsystems underscores its importance in maintaining the engine’s performance and reliability.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.