This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3923204 Plain Hose Coupling is a component designed for use in commercial truck systems. It facilitates the connection between hoses in fluid transfer applications, ensuring a secure and leak-free seal. This coupling is integral to maintaining the efficiency and reliability of fluid systems in heavy-duty trucks.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are mechanical devices used to join two hoses or a hose to a fitting without the need for clamps or additional fasteners. They operate by compressing the hose between two flanges, creating a tight seal that allows for the transfer of fluids under pressure. These couplings are commonly used in various fluid transfer systems, including hydraulic, pneumatic, and fuel systems, due to their simplicity and effectiveness 1.

Purpose and Role in Truck Operation

The Cummins 3923204 Plain Hose Coupling serves a specific function in commercial trucks by enabling the secure connection of hoses in fluid transfer systems. It plays a role in ensuring that fluids such as hydraulic oil, coolant, or fuel are transferred efficiently and without leakage. Its design allows for easy integration into existing systems, contributing to the overall reliability and performance of the truck’s fluid systems 2.

Key Features

The Cummins 3923204 Plain Hose Coupling is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The design includes precision-machined flanges that provide a secure seal, and it may feature unique attributes such as reinforced hose ends to prevent damage during installation or operation 3.

Benefits

The use of the Cummins 3923204 Plain Hose Coupling offers several benefits. It provides improved reliability in fluid transfer systems, reducing the risk of leaks and system failures. The design of the coupling allows for ease of installation, minimizing downtime during maintenance procedures. Additionally, its robust construction and secure seal contribute to lower maintenance requirements over time.

Installation Process

Installing the Cummins 3923204 Plain Hose Coupling involves several steps to ensure a proper and secure connection. First, the hose ends should be prepared by cutting them to the appropriate length and ensuring they are free of debris. The coupling is then positioned over one hose end, and the second hose is inserted into the opposite side. Using the provided tool, the coupling is compressed, bringing the flanges together to create a seal. It is important to follow the manufacturer’s guidelines for torque specifications to ensure the coupling is properly secured.

Common Applications

The Cummins 3923204 Plain Hose Coupling is versatile and finds applications in various commercial truck systems. It is commonly used in hydraulic systems for brake and steering applications, in coolant systems for engine temperature management, and in fuel systems for efficient fuel delivery. Its ability to provide a secure and leak-free connection makes it a valuable component in maintaining the performance and reliability of these systems.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Cummins 3923204 Plain Hose Coupling, regular maintenance and troubleshooting are recommended. Common issues may include leaks due to improper installation or wear on the hose ends. Diagnostic procedures should involve inspecting the coupling for signs of damage or corrosion and ensuring that the hose ends are properly seated within the coupling. Maintenance practices may include periodic re-torqueing of the coupling to maintain a secure seal and replacing worn or damaged components as needed.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 3923204 Plain Hose Coupling, it is important to observe several safety guidelines. Ensure that the system is depressurized before beginning any work to prevent injury from fluid release. Use the appropriate tools and follow torque specifications to avoid over-tightening, which can damage the coupling or hose. Additionally, wear protective equipment such as gloves and safety glasses to protect against potential hazards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various industries, including transportation, construction, and agriculture.

Compatibility of Cummins Part 3923204 with Various Cummins Engines

The Cummins part 3923204, a Plain Hose Coupling, is designed to fit seamlessly with a range of Cummins engines, ensuring efficient and reliable performance. This part is engineered to meet the specific needs of various engine models, providing a secure connection for hoses and ensuring optimal fluid flow.

Compatibility with 4B3.9, 6B5.9, B4.5, G8.3, and G855 Engines

The Plain Hose Coupling 3923204 is compatible with the 4B3.9, 6B5.9, B4.5, G8.3, and G855 engines. These engines are known for their robust design and performance, and the hose coupling ensures that the hose connections remain intact under various operating conditions, maintaining the integrity of the engine’s fluid systems.

Compatibility with ISB and ISBE Engines

The ISB CM550, ISB CM850, and ISBE CM800 engines also benefit from the use of the Cummins part 3923204. These engines are part of Cummins’ Intelligent Systems for Better Efficiency (ISB) series, designed to deliver high performance and efficiency. The hose coupling ensures that the fluid systems within these engines operate smoothly, preventing leaks and maintaining pressure.

Compatibility with ISC and ISL Engines

The ISC CM554 and ISC CM850 engines, as well as the ISL CM554 and ISL9 CM2150 SN engines, are also compatible with the Plain Hose Coupling 3923204. These engines are known for their durability and reliability, and the hose coupling plays a crucial role in maintaining the integrity of the engine’s fluid systems.

Compatibility with L10 GAS and N14 G Engines

The L10 GAS and N14 G engines are designed for heavy-duty applications, and the Cummins part 3923204 ensures that the hose connections remain secure under demanding conditions. This compatibility is essential for maintaining the performance and longevity of these engines.

Compatibility with QSB and QSC Engines

The QSB5.9 44 CM550, QSB5.9 CM550, QSC8.3 CM554, and QSL9 CM554 engines also utilize the Plain Hose Coupling 3923204. These engines are part of Cummins’ Quantum Series, known for their advanced technology and performance. The hose coupling ensures that the fluid systems within these engines operate efficiently, preventing leaks and maintaining pressure.

Role of Part 3923204 Plain Hose Coupling in Engine Systems

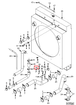

The Part 3923204 Plain Hose Coupling is an essential component in the fluid dynamics of various engine systems. It facilitates the secure and efficient connection between hoses, ensuring the smooth transfer of fluids such as engine coolant, exhaust gases, and other vital substances.

In the turbocharger arrangement, the Plain Hose Coupling connects the turbocharger to the exhaust system. This connection allows for the efficient transfer of exhaust gases, which are used to spin the turbine and compress the intake air, thereby enhancing engine performance.

Within the cooling system, the Plain Hose Coupling plays a significant role by linking the water outlet to the thermostat housing. This ensures a consistent flow of coolant from the engine to the radiator, maintaining optimal engine temperature and preventing overheating.

The coupling also interfaces with the heat exchanger, where it connects the coolant lines to facilitate the transfer of heat between the engine coolant and the ambient air, further aiding in temperature regulation.

In systems involving exhaust gas recirculation (EGR), the Plain Hose Coupling connects the EGR valve to the intake manifold. This allows for the recirculation of a portion of the exhaust gases back into the intake, reducing nitrogen oxides (NOx) emissions and improving combustion efficiency.

Additionally, the coupling is used in the connection between the expansion tank and the coolant reservoir. This setup allows for the safe expansion and contraction of coolant as it heats up and cools down, preventing pressure build-up and potential leaks.

The Plain Hose Coupling also finds its application in the electronic governor systems, where it ensures the secure connection of various fluid lines that are integral to the governor’s operation, thus maintaining precise control over engine parameters.

Lastly, in the radiator setup, the coupling connects the radiator to the engine coolant lines, ensuring efficient heat dissipation and maintaining the engine within its optimal operating temperature range.

Conclusion

The Cummins 3923204 Plain Hose Coupling is a versatile and reliable component essential for the efficient operation of fluid systems in commercial trucks and various Cummins engines. Its design, featuring high-quality materials and precision-machined flanges, ensures durability and a secure seal. The coupling’s compatibility with a wide range of Cummins engines highlights its importance in maintaining the performance and reliability of these engines. Regular maintenance and adherence to safety guidelines are crucial for ensuring the longevity and optimal performance of this part.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Martyr, A. J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.