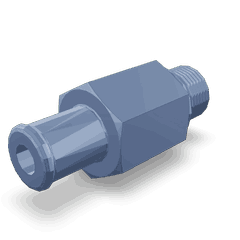

The 3965003 Plain Hose Coupling, a component manufactured by Cummins, is designed for use in commercial trucks to facilitate the transfer of fluids within the vehicle’s systems. Cummins is recognized for its commitment to quality and innovation in manufacturing automotive components, and this Cummins part is no exception.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are devices used to connect two ends of a hose, enabling the transfer of fluids such as coolant, fuel, or hydraulic fluid. They are integral to fluid transfer systems in the automotive industry, providing a secure and leak-proof connection that can withstand the pressures and temperatures associated with these systems. Plain hose couplings are valued for their simplicity, reliability, and ease of use 1.

Role of the 3965003 Plain Hose Coupling in Truck Operation

In the operation of commercial trucks, the 3965003 Plain Hose Coupling ensures a consistent and secure connection between hoses, which is vital for the efficient operation of the truck’s systems. By maintaining a reliable fluid transfer pathway, this coupling contributes to the overall performance and reliability of the vehicle 2.

Key Features of the 3965003 Plain Hose Coupling

The 3965003 Plain Hose Coupling is constructed from high-quality materials that are resistant to corrosion and wear, ensuring a long service life. The design of the coupling includes elements that facilitate easy installation and removal, as well as a secure connection that minimizes the risk of leaks. Additionally, the coupling may feature unique attributes such as a reinforced hose end or a specialized clamp mechanism to further improve its functionality 3.

Benefits of Using the 3965003 Plain Hose Coupling

Utilizing the 3965003 Plain Hose Coupling offers several benefits. It contributes to improved efficiency in fluid transfer systems by providing a secure and leak-proof connection. The coupling’s durable construction ensures longevity, reducing the need for frequent replacements. Its design allows for ease of installation, minimizing downtime during maintenance procedures. Furthermore, the coupling’s maintenance advantages, such as straightforward inspection and cleaning routines, contribute to the overall efficiency of truck maintenance operations.

Installation Process

Installing the 3965003 Plain Hose Coupling involves several steps to ensure a secure and effective connection. Begin by preparing the hose ends to be connected, ensuring they are clean and free of debris. Slide the coupling onto one of the hose ends, then connect the second hose end to the coupling. Use the appropriate tools to tighten the coupling, ensuring a snug fit without over-tightening, which could damage the hose or the coupling itself. Follow best practices to verify the connection’s integrity, such as checking for leaks under pressure.

Troubleshooting Common Issues

Common issues with the 3965003 Plain Hose Coupling may include leaks or disconnections. To address these problems, first, ensure that the coupling is properly installed and tightened. Inspect the hose ends for damage or wear that could prevent a secure connection. If leaks persist, consider replacing the coupling or the affected hose section. Regular inspections and maintenance can help identify and resolve issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3965003 Plain Hose Coupling, regular maintenance is recommended. This includes routine inspections for signs of wear, corrosion, or damage. Cleaning the coupling and hose ends can prevent the buildup of debris that could affect the connection’s integrity. Additionally, verifying the tightness of the coupling during maintenance checks can help ensure a secure connection and prevent leaks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to quality and innovation is evident in its manufacturing processes and the performance of its products, including the 3965003 Plain Hose Coupling.

Cummins Engine Compatibility with Part 3965003

The Plain Hose Coupling, part number 3965003, manufactured by Cummins, is designed to integrate seamlessly with several Cummins engine models. This part is essential for maintaining the integrity of the engine’s fluid systems, ensuring that hoses are securely connected without leaks or disconnections.

ISB CM850 Engines

The ISB CM850 engine series is a robust and reliable option for various applications, including heavy-duty trucks and industrial machinery. The Plain Hose Coupling 3965003 fits perfectly within this engine series, providing a critical connection point for fluid lines. This coupling ensures that the engine’s cooling, fuel, and other fluid systems operate efficiently and safely.

Group Compatibility

While the Plain Hose Coupling 3965003 is specifically designed for the ISB CM850 engines, it is also compatible with other Cummins engine groups that utilize similar hose configurations. This compatibility extends to various models within the Cummins engine lineup, ensuring that the part can be used across different applications and machinery types.

The design of the Plain Hose Coupling 3965003 is engineered to meet the stringent requirements of Cummins engines, ensuring durability and reliability in demanding environments. Its straightforward yet effective design allows for easy installation and maintenance, making it a preferred choice for technicians and operators alike.

Role of Part 3965003 Plain Hose Coupling in Engine Systems

The part 3965003 Plain Hose Coupling is an essential component in various engine systems, facilitating the secure and efficient connection of hoses to different parts of the engine. Its application spans across multiple systems, enhancing both performance and reliability.

Plumbing Systems

In plumbing systems, the Plain Hose Coupling ensures a leak-free connection between hoses and pipes. This is particularly important in systems where fluids such as coolant or fuel are transported. The coupling’s design allows for easy installation and removal, making maintenance and repairs more straightforward. It also accommodates slight misalignments between hoses, which is common in dynamic engine environments, thereby reducing the risk of leaks and ensuring consistent fluid flow.

Exhaust Recirculation Systems

For exhaust recirculation (EGR) systems, the Plain Hose Coupling plays a significant role in connecting hoses that carry exhaust gases back into the intake manifold. This process helps reduce nitrogen oxides (NOx) emissions, contributing to a cleaner combustion process. The coupling’s robust construction withstands the high temperatures and pressures associated with exhaust gases, ensuring a durable and reliable connection. Its use in EGR systems enhances engine efficiency and compliance with emissions regulations.

Water Systems

In water systems, such as those used for cooling or washing purposes within the engine compartment, the Plain Hose Coupling provides a dependable connection for hoses that transport water. Whether it’s for cooling components like the radiator or for cleaning applications, the coupling ensures that water flows smoothly without interruptions. Its resistance to corrosion and various chemicals makes it suitable for long-term use in these environments, maintaining the integrity of the water system and supporting overall engine health.

Conclusion

The 3965003 Plain Hose Coupling is a critical component in the fluid transfer systems of commercial trucks, ensuring secure and efficient connections between hoses. Its durable construction, ease of installation, and maintenance advantages contribute to the overall performance and reliability of the vehicle. Regular maintenance and proper installation practices are essential to maximize the benefits of this Cummins part.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩ -

The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Pawel Drozdziel, Routledge, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.