4934496

Plain Hose Coupling

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4934496 Plain Hose Coupling, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. This coupling is essential for connecting various fluid systems in commercial trucks, ensuring efficient and reliable operation.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are devices used to join two hoses or a hose to a fitting in fluid systems. They facilitate the transfer of liquids or gases by providing a secure and leak-proof connection. These couplings operate by compressing the hose between two flanges, creating a seal that prevents fluid leakage while allowing for easy disconnection and reconnection as needed 1.

Purpose of the 4934496 Plain Hose Coupling

In commercial trucks, the 4934496 Plain Hose Coupling connects different sections of hoses within the truck’s fluid systems, including fuel, coolant, and hydraulic lines. This ensures efficient fluid transport throughout the vehicle, contributing to overall performance and reliability 2.

Key Features

The 4934496 Plain Hose Coupling is constructed from durable materials that can withstand the pressures and temperatures encountered in commercial truck applications. Its design includes precision-machined flanges that ensure a tight seal, minimizing the risk of leaks. Additionally, it features a straightforward design that allows for easy installation and removal, facilitating maintenance and repairs 3.

Benefits

The advantages of using the 4934496 Plain Hose Coupling include its durability, ease of installation, and reliability under various operating conditions. These features make it a preferred choice for commercial truck applications, where consistent performance is paramount 4.

Installation Process

Installing the 4934496 Plain Hose Coupling involves several steps to ensure a secure and leak-free connection. First, the hoses to be connected should be prepared by ensuring they are clean and free of any debris. The coupling is then positioned over the hose ends, and the flanges are tightened using the appropriate tools to compress the hose and create a seal. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the hose or coupling 1.

Maintenance Tips

To ensure the longevity and optimal performance of the 4934496 Plain Hose Coupling, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, such as cracks or leaks. Cleaning the coupling and surrounding areas can prevent the accumulation of debris that might affect its operation. Additionally, checking the tightness of the flanges at recommended intervals can help maintain a secure connection 2.

Troubleshooting Common Issues

Common problems associated with plain hose couplings can include leaks, difficulty in disconnection, or hose damage. To address these issues, first, ensure that the coupling is correctly installed and tightened to the manufacturer’s specifications. If a leak is detected, inspect the hose and coupling for damage and replace any compromised parts. Difficulty in disconnection may indicate over-tightening or the need for lubrication on the flanges 3.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation among professionals and enthusiasts alike. Their dedication to advancing technology and maintaining high standards in manufacturing ensures that their products, like the 4934496 Plain Hose Coupling, meet the demanding requirements of commercial truck applications 4.

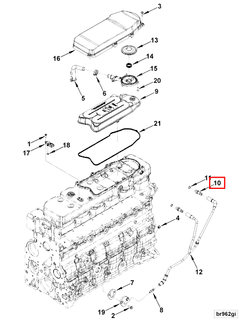

Role of 4934496 Plain Hose Coupling in Engine Systems

The 4934496 Plain Hose Coupling is instrumental in ensuring the seamless operation of various engine systems. In the context of a breather system, this coupling facilitates the connection between the breather hose and the crankcase, allowing for the regulated release of pressure and contaminants from the crankcase. This helps maintain optimal engine performance and longevity.

When integrated with the crankcase ventilation system, the Plain Hose Coupling ensures that the crankcase remains at an appropriate pressure, preventing the buildup of harmful gases and moisture. This is essential for the efficient operation of the engine and the prevention of oil contamination.

In a long block assembly, the coupling is used to connect various hoses that are part of the engine’s ancillary systems. This includes connections to the breather and ventilation systems, ensuring that the long block operates within specified parameters.

For a long block kit, which often includes a variety of hoses and fittings, the Plain Hose Coupling serves as a reliable connector that can be easily installed and removed. This simplifies the assembly and disassembly processes, making maintenance and upgrades more straightforward.

The coupling also plays a significant role in the vent system of the engine. By providing a secure and leak-proof connection, it ensures that vented gases are properly directed away from the engine compartment, contributing to a safer and more efficient operating environment.

Lastly, in systems involving engine coolant, the Plain Hose Coupling can be used to connect hoses in the cooling system. This ensures that coolant flows smoothly through the engine, maintaining optimal temperatures and preventing overheating.

Overall, the 4934496 Plain Hose Coupling is a versatile component that enhances the functionality and reliability of various engine systems.

Conclusion

The 4934496 Plain Hose Coupling by Cummins is a vital component in the maintenance and operation of commercial trucks and various engine systems. Its durable construction, ease of installation, and reliable performance make it an essential part for ensuring efficient fluid transfer and maintaining the integrity of engine systems.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ ↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ ↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩ ↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.