This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

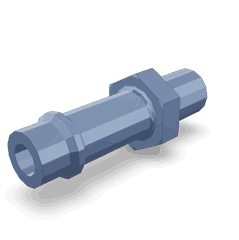

The Cummins 5298148 Plain Hose Coupling is a component designed for use in commercial truck systems. Its primary role is to facilitate the secure connection of hoses, ensuring efficient fluid transfer within the truck’s system. This coupling is integral to maintaining the integrity and functionality of fluid transfer lines in commercial vehicles.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are devices used to connect hoses in fluid transfer systems. They operate by providing a secure, leak-proof connection between two hose ends, allowing for the uninterrupted flow of fluids. These couplings are commonly used in various applications, including automotive, industrial, and commercial systems, where reliable fluid transfer is necessary 1.

Purpose and Role in Truck Operation

The Cummins 5298148 Plain Hose Coupling serves a specific purpose in commercial truck operations by connecting hoses and facilitating the transfer of fluids such as coolant, fuel, or hydraulic fluid. This coupling ensures that the connection between hoses is secure, minimizing the risk of leaks and maintaining the efficiency of the fluid transfer system. Its role is vital in ensuring that the truck’s systems operate smoothly and reliably.

Key Features

The Cummins 5298148 Plain Hose Coupling is characterized by several key features that enhance its performance and durability. These include a robust material composition, typically made from high-quality rubber or synthetic materials, which provides resistance to wear and environmental factors. The design attributes of this coupling, such as its ease of installation and secure locking mechanism, contribute to its effectiveness in commercial truck applications.

Benefits

The Cummins 5298148 Plain Hose Coupling offers several benefits, including improved reliability in fluid transfer systems. Its design allows for easy installation, reducing downtime during maintenance procedures. Additionally, the coupling’s durability and resistance to leaks contribute to lower maintenance requirements, making it a cost-effective solution for commercial truck operators.

Installation Process

Proper installation of the Cummins 5298148 Plain Hose Coupling involves several steps to ensure a secure and leak-proof connection. Begin by preparing the hose ends to be connected, ensuring they are clean and free of debris. Insert one hose end into the coupling, followed by the second hose end. Once both hoses are in place, use the coupling’s locking mechanism to secure the connection. It is important to follow manufacturer guidelines to avoid common pitfalls such as improper alignment or insufficient tightening, which can lead to leaks or connection failure.

Common Issues and Troubleshooting

Common issues with plain hose couplings may include leaks, difficulty in installation, or coupling failure due to wear and tear. Troubleshooting these problems often involves inspecting the coupling for signs of damage or wear, ensuring that the hoses are properly aligned and securely connected. In cases of leaks, tightening the coupling or replacing damaged components may be necessary to restore functionality.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 5298148 Plain Hose Coupling, routine maintenance practices are recommended. These include regular inspection of the coupling for signs of wear, damage, or leaks. Cleaning the coupling and surrounding areas to remove debris and contaminants can also help prevent issues. Following manufacturer guidelines for inspection intervals and maintenance procedures will contribute to the reliable operation of the fluid transfer system.

Safety Considerations

When working with plain hose couplings, it is important to follow safety precautions to prevent accidents and ensure personal safety. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses. Additionally, ensuring that the work area is well-ventilated and free of flammable materials is crucial when dealing with fluid transfer systems. Following manufacturer safety guidelines and procedures will help maintain a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of commercial vehicle operators, including engines, powertrain components, and aftermarket parts. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Engine Compatibility with Part 5298148

The Plain Hose Coupling part 5298148, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is integral in ensuring the proper connection and functionality of hoses within the engine system. Below is a detailed description of its compatibility with specific engine models:

B6.7 CM2350 Series

The Plain Hose Coupling part 5298148 is compatible with the following B6.7 CM2350 engines:

- B6.7 CM2350 B135B

- ISB6.7 CM2350 B101

These engines are part of the B6.7 CM2350 series, which is known for its robust performance and reliability. The part 5298148 ensures that hose connections are secure and leak-free, contributing to the overall efficiency and maintenance of these engines.

ISB6.7 G CM2180 Series

The Plain Hose Coupling part 5298148 also fits the following ISB6.7 G CM2180 engine:

- ISB6.7 G CM2180 B118

This engine model is part of the ISB6.7 G CM2180 series, which is designed for high-performance applications. The part 5298148 is engineered to meet the stringent requirements of these engines, ensuring durability and ease of maintenance.

Compatibility Summary

The Plain Hose Coupling part 5298148 is a versatile component that fits into the following Cummins engine models:

- B6.7 CM2350 B135B

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

This part is essential for maintaining the integrity of hose connections, which is crucial for the proper functioning and longevity of these engines.

Role of Part 5298148 Plain Hose Coupling in Engine Systems

The 5298148 Plain Hose Coupling is an essential component in various engine systems, facilitating the secure and efficient connection of hoses to other components.

Integration with Upfit Kit

When integrating with an upfit kit, the 5298148 Plain Hose Coupling ensures that additional systems or accessories can be seamlessly connected to the engine’s existing hose network. This allows for the efficient transfer of fluids or gases without the risk of leaks, which is vital for the proper functioning of upfitted systems.

Functionality in Vent Systems

In vent systems, the 5298148 Plain Hose Coupling plays a significant role in maintaining the integrity of the ventilation network. It connects vent hoses to various components, ensuring that air or gases are properly directed and expelled from the engine compartment. This helps in regulating temperature and pressure, contributing to the overall efficiency and safety of the engine system.

Application in Engine Coolant Systems

Within engine coolant systems, the 5298148 Plain Hose Coupling is used to connect hoses that transport coolant between the engine block, radiator, and other cooling system components. This ensures a consistent flow of coolant, which is essential for dissipating heat and preventing engine overheating. The reliable connection provided by the coupling is key to maintaining optimal engine performance and longevity.

Conclusion

The Cummins 5298148 Plain Hose Coupling is a critical component in commercial truck systems, ensuring secure and efficient fluid transfer. Its compatibility with various Cummins engines, ease of installation, and robust design make it a reliable choice for maintaining the integrity of fluid transfer lines. Regular maintenance and adherence to safety guidelines are essential for maximizing the performance and longevity of this coupling.

-

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.