3095355

Jaw Coupling Hub

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3095355 Jaw Coupling Hub, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-quality components. The 3095355 is significant in the operation of commercial trucks, contributing to the efficient transmission of power between various mechanical components.

Basic Concepts of Jaw Coupling Hubs

A Jaw Coupling Hub is a type of mechanical coupling that connects two shafts, allowing for the transfer of torque and rotation. It operates on the principle of interlocking “jaws” that engage with each other, providing a flexible yet robust connection. This design allows for some degree of misalignment between the shafts, which can occur due to thermal expansion, wear, or other factors. Jaw couplings are widely used in various machinery due to their durability, ease of installation, and maintenance-friendly design 1.

Purpose of the 3095355 Jaw Coupling Hub in Truck Operation

The 3095355 plays a role in the operation of a truck by connecting different components and facilitating the efficient transmission of power. It is typically used to link the engine to the transmission or other drivetrain components. By providing a secure and flexible connection, it ensures that power is transmitted smoothly, even under varying operational conditions 2.

Key Features of the 3095355 Jaw Coupling Hub

The 3095355 features a design that includes precision-machined jaws made from high-strength materials. These materials are chosen for their durability and resistance to wear, ensuring long-term performance. The hub is engineered to accommodate minor misalignments, which helps in reducing stress on connected components and prolonging their lifespan. Additionally, its design allows for easy installation and removal, which simplifies maintenance procedures 3.

Benefits of Using the 3095355 Jaw Coupling Hub

Incorporating the 3095355 into truck systems offers several advantages. It contributes to improved efficiency by ensuring a smooth transfer of power, which can lead to better overall performance of the truck. The design of the hub reduces the need for frequent maintenance, as it is built to withstand the rigors of commercial truck operation. Furthermore, its ability to accommodate misalignments helps in protecting other components from undue stress, potentially leading to fewer repairs and downtime 4.

Installation and Integration

Proper installation of the 3095355 is vital for ensuring optimal performance. It should be aligned correctly with the shafts it connects to minimize the risk of misalignment issues. Following the manufacturer’s guidelines for torque settings and ensuring that all components are clean and free from debris before installation are best practices. Regular checks post-installation can help in identifying any issues early on.

Troubleshooting Common Issues

Common problems associated with Jaw Coupling Hubs can include wear on the jaws, misalignment, or contamination. Regular inspections can help in identifying these issues early. If wear is detected, replacement of the affected parts may be necessary. Misalignment can often be corrected by adjusting the connected components, while contamination can be addressed by cleaning the hub and ensuring that it is properly sealed against ingress of dirt or moisture.

Maintenance Practices

To ensure the longevity and reliable performance of the 3095355, regular maintenance routines are recommended. This includes periodic inspections for signs of wear or damage, cleaning the hub to remove any contaminants, and ensuring that all connections are secure. Following these practices can help in maintaining efficient operation and preventing unexpected failures.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long history in the automotive industry. The company is known for its commitment to producing high-quality components that meet the demanding requirements of commercial applications. Cummins’ reputation is built on a foundation of innovation, reliability, and customer satisfaction, making it a trusted name in the industry.

Jaw Coupling Hub (Part 3095355) Compatibility with Cummins Engines

The Jaw Coupling Hub, part number 3095355, is a critical component in the power transmission system of various Cummins engines. This part is designed to connect the engine to the transmission, ensuring efficient power transfer and smooth operation. Below is a detailed description of its compatibility with different Cummins engine models.

ISM Series

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, are designed for heavy-duty applications, often found in construction and mining equipment. The Jaw Coupling Hub (part 3095355) is integral to these engines, providing a reliable connection between the engine and the transmission, ensuring optimal performance under heavy loads.

ISX Series

- ISX CM570

- ISX CM870

- ISX CM871

The ISX series engines, such as the ISX CM570, ISX CM870, and ISX CM871, are known for their high power output and efficiency. These engines are commonly used in on-highway and vocational applications. The Jaw Coupling Hub (part 3095355) is essential for these engines, facilitating the transfer of power from the engine to the transmission, ensuring smooth and efficient operation.

Celect Series

- L10 CELECT

- M11 CELECT

- M11 CELECT PLUS

- N14 CELECT PLUS

The Celect series engines, including the L10 CELECT, M11 CELECT, M11 CELECT PLUS, and N14 CELECT PLUS, are designed for on-highway applications. These engines are known for their advanced technology and fuel efficiency. The Jaw Coupling Hub (part 3095355) is a key component in these engines, ensuring a secure and efficient connection between the engine and the transmission.

QSM11 and QSNT14 Series

- QSM11 CM570

- QSM11 CM876

- QSNT14 CM876 N102

The QSM11 and QSNT14 series engines, such as the QSM11 CM570, QSM11 CM876, and QSNT14 CM876 N102, are designed for heavy-duty applications, often found in construction and mining equipment. The Jaw Coupling Hub (part 3095355) is crucial for these engines, providing a reliable and efficient connection between the engine and the transmission, ensuring optimal performance under heavy loads.

QSN14 Series

- QSN14 CM876 N103

The QSN14 CM876 N103 engine is designed for heavy-duty applications, often found in construction and mining equipment. The Jaw Coupling Hub (part 3095355) is a critical component for this engine, ensuring a secure and efficient connection between the engine and the transmission, facilitating optimal performance under heavy loads.

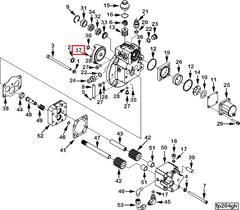

Role of Part 3095355 Jaw Coupling Hub in Engine Systems

The 3095355 is integral to the efficient operation of various engine systems. It facilitates the seamless transfer of rotational force between the engine components, ensuring smooth and reliable performance.

Integration with Fuel Systems

In fuel systems, the Jaw Coupling Hub works in conjunction with the Celect Fuel Pump and Fuel Base Pump. It ensures that the rotational motion from the engine is effectively transmitted to these pumps, allowing for consistent fuel delivery to the Injector and Injector Nozzle. This reliable transfer of motion is essential for maintaining the precise fuel injection timing required for optimal engine performance.

Coordination with Engine Components

The Jaw Coupling Hub also plays a significant role in coordinating with the Engine Piston. By providing a stable and efficient connection between the piston and other moving parts, it helps in maintaining the engine’s overall balance and reducing wear on components. This connection is vital for the consistent operation of the piston, which in turn affects the engine’s power output and fuel efficiency.

Enhancing Pump Performance

When integrated with various Pump components, such as the Fuel Pump and Fuel Injection Pump, the Jaw Coupling Hub ensures that these pumps operate at their designed efficiency. It minimizes energy loss during the transfer of rotational force, which is crucial for the pumps to deliver fuel at the correct pressure and volume. This efficient operation is key to achieving the desired engine performance and fuel economy.

Supporting Mounting and Stability

The Jaw Coupling Hub also supports the Mounting of engine components. By providing a robust and flexible connection, it helps in absorbing vibrations and reducing stress on the mounting points. This stability is important for the longevity of the engine parts and the overall reliability of the engine system.

Conclusion

In summary, the 3095355 is a vital component that enhances the performance and reliability of engine systems by ensuring efficient force transfer, consistent fuel delivery, and stable component operation. Its integration into various engine components and systems underscores its importance in maintaining the overall efficiency and reliability of commercial trucks.

-

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

The Dynamic Behavior of a Diesel Engine, S. A. Miedema, Z. Lu, Published by Drir S. A. Miedema, 2010

↩ -

Vehicle Noise, Vibration and Sound Quality, Gang Sheng, SAE International, 2012

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif Ed, Springer Vieweg, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.