This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

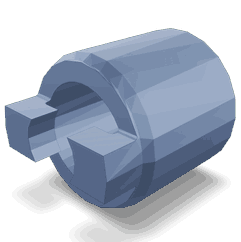

The Jaw Coupling Hub 3914707, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part is significant in this context, as it plays a role in the mechanical systems of trucks, ensuring smooth operation and performance.

Basic Concepts of Jaw Coupling Hubs

Jaw coupling hubs are mechanical devices used to connect two shafts in a system, allowing for the transmission of torque while accommodating minor misalignments between the shafts. They consist of two hubs with interlocking “jaws” that grip each other, providing a flexible yet robust connection. This design allows for a degree of angular, parallel, and axial misalignment, which is common in dynamic mechanical systems. Jaw couplings are widely used in various industries due to their reliability, ease of installation, and maintenance-friendly design 1.

Purpose of the 3914707 Jaw Coupling Hub

This part serves a specific function within the operation of a truck. It is responsible for transmitting torque between the engine and the transmission, or between other components within the drivetrain. This hub is designed to handle the high torque loads typical in commercial trucks while also accommodating any misalignment that may occur due to the vehicle’s operation or the wear and tear on its components. By doing so, it contributes to the smooth and efficient transfer of power throughout the truck’s mechanical system.

Key Features

The 3914707 is characterized by several key features that enhance its performance. Its design incorporates precision-machined jaws that ensure a secure grip and efficient torque transmission. The hub is constructed from high-strength materials, which provide durability and resistance to wear. Additionally, the hub may feature unique attributes such as corrosion-resistant coatings or specialized lubrication systems to further improve its operational lifespan and performance under demanding conditions 2.

Benefits of Using the 3914707 Jaw Coupling Hub

Utilizing this part in truck operations offers several advantages. Its design contributes to improved efficiency by ensuring a smooth and consistent transfer of torque. The hub’s ability to accommodate misalignment reduces stress on connected components, potentially leading to increased durability of the entire drivetrain. Furthermore, the reliability of the jaw coupling design means that trucks equipped with this hub may experience fewer downtimes due to mechanical failures, enhancing overall operational reliability.

Installation Considerations

Proper installation of the 3914707 is vital to ensure optimal performance and longevity. Guidelines for installation include ensuring that the shafts are clean and free from debris before coupling, aligning the hubs correctly to minimize initial misalignment, and tightening the coupling to the manufacturer’s specified torque settings. Following these best practices helps to prevent premature wear and ensures that the hub functions as intended within the truck’s mechanical system.

Common Issues and Troubleshooting

Despite their robustness, jaw coupling hubs like the 3914707 may encounter issues over time. Common problems include wear on the jaws, misalignment due to shaft wear, or contamination within the coupling. Troubleshooting steps may involve inspecting the coupling for signs of wear, realigning or replacing worn components, and cleaning the coupling to remove any contaminants. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s drivetrain.

Maintenance Tips

Routine maintenance is key to keeping the 3914707 in good working condition. Maintenance practices should include regular inspections for signs of wear or damage, cleaning the coupling to prevent contamination, and ensuring that all connections are secure and aligned. Following manufacturer-recommended inspection intervals and care procedures can help extend the lifespan of the hub and maintain its performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 3.

Compatibility with Cummins Engines

This part is engineered to fit seamlessly with several Cummins engine models. Below is a detailed breakdown of its compatibility:

-

4B3.9 and 6B5.9 Engines: These engines, known for their robust performance and reliability, utilize the 3914707 to maintain a strong connection between the engine and transmission. This ensures smooth power delivery and reduces wear and tear on the engine components.

-

ISB CM550, ISC CM554, ISL CM554, QSC8.3 CM554, and QSL9 CM554 Engines: The ISB, ISC, ISL, QSC, and QSL series engines are part of Cummins’ lineup of high-performance, fuel-efficient engines. The 3914707 is specifically designed to interface with these engines, providing a reliable and durable connection. This is crucial for maintaining the integrity of the power transmission system and ensuring optimal engine operation.

By ensuring a precise fit and reliable performance, the 3914707 plays a vital role in the overall functionality and longevity of these Cummins engines.

Role of the 3914707 in Various Systems

The 3914707 is an essential component in ensuring the smooth operation of various mechanical systems. Its primary function is to connect rotating shafts while accommodating minor misalignments, which is vital in maintaining the efficiency and longevity of the equipment.

Air Compressor Systems

In air compressor systems, the 3914707 is utilized to link the motor shaft to the compressor shaft. This connection allows for the transfer of rotational force from the motor to the compressor, enabling the compression of air. The hub’s ability to handle misalignments ensures that the compressor operates smoothly, reducing wear and tear on both the motor and the compressor.

Hydraulic Pump Systems

For hydraulic pump systems, the 3914707 plays a significant role in connecting the drive motor to the pump. This ensures that the motor’s rotational energy is efficiently transferred to the pump, facilitating the movement of hydraulic fluid. The hub’s design helps in minimizing stress on the system components, leading to enhanced performance and reliability of the hydraulic system.

Vacuum Pump Systems

In vacuum pump applications, the 3914707 is employed to couple the motor shaft to the vacuum pump shaft. This connection is essential for the pump to generate the necessary vacuum by rotating the impeller or other pumping mechanisms. The hub’s flexibility in accommodating shaft misalignments contributes to the stable and consistent operation of the vacuum pump, which is crucial for applications requiring precise vacuum levels.

Conclusion

The 3914707 Jaw Coupling Hub is a critical component in the operation of commercial trucks and various mechanical systems. Its design and features contribute to the efficient transfer of torque, accommodation of misalignments, and overall reliability of the systems it serves. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and performance of this part in demanding applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.