This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

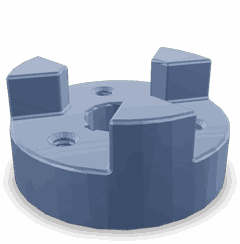

The Cummins 4061677 Jaw Coupling Hub is a specialized component designed for heavy-duty truck applications. It plays a role in the drivetrain system by facilitating the efficient transfer of power from the engine to the transmission. This hub is integral to maintaining the smooth operation and reliability of heavy-duty trucks, ensuring that power is transmitted effectively under demanding conditions.

Basic Concepts of Jaw Coupling Hubs

Jaw coupling hubs are mechanical devices used to connect two rotating shafts. They consist of two hubs with interlocking jaws that transmit torque between the shafts. These couplings are known for their flexibility, allowing for minor misalignments between shafts, which can occur due to thermal expansion or other operational factors. Jaw couplings are widely used in various mechanical systems due to their durability, ease of installation, and maintenance-friendly design 1.

Purpose and Role in Truck Operation

The Cummins 4061677 Jaw Coupling Hub plays a specific role in the operation of a truck by connecting the engine to the transmission. Positioned within the drivetrain, this hub ensures that power generated by the engine is efficiently transmitted to the transmission, enabling the truck to move. It accommodates slight misalignments and absorbs shocks and vibrations, contributing to the overall stability and performance of the vehicle 2.

Key Features

The Cummins 4061677 Jaw Coupling Hub is characterized by several key features that enhance its performance and durability. Its design includes precision-machined jaws that ensure a secure and efficient transfer of torque. The hub is constructed from high-strength materials, providing resistance to wear and fatigue. Additionally, it features a compact design that allows for easy installation and maintenance, making it a reliable choice for heavy-duty applications.

Benefits

The Cummins 4061677 Jaw Coupling Hub offers several advantages in heavy-duty truck applications. It contributes to improved efficiency by ensuring a smooth and consistent transfer of power. The hub’s design reduces maintenance requirements, as it is built to withstand the rigors of heavy-duty use with minimal need for intervention. Furthermore, its reliability enhances the overall performance and longevity of the truck’s drivetrain system.

Installation Considerations

Proper installation of the Cummins 4061677 Jaw Coupling Hub is crucial for ensuring optimal performance and longevity. It is important to follow alignment requirements to prevent undue stress on the coupling and connected shafts. Torque specifications should be adhered to during installation to ensure that the hub is securely fastened without overtightening, which could lead to damage. Careful attention to these details will help maintain the integrity and efficiency of the drivetrain system.

Troubleshooting Common Issues

Common problems associated with jaw coupling hubs can include misalignment, wear on the jaws, and lubrication issues. Misalignment may result from improper installation or changes in the drivetrain components over time. Wear on the jaws can occur due to excessive torque or insufficient lubrication. Regular inspection and maintenance can help identify these issues early. Troubleshooting steps may involve realigning the shafts, replacing worn components, or ensuring proper lubrication to address these common problems effectively.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4061677 Jaw Coupling Hub, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage on the jaws and ensuring that alignment is maintained. Lubrication is also important; following the manufacturer’s recommendations for lubrication intervals and types can prevent wear and reduce friction. Adhering to these maintenance tips will help maintain the efficiency and reliability of the jaw coupling hub.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company offers a wide range of products designed to meet the demanding requirements of various applications, ensuring that customers receive high-performance solutions for their power needs.

Jaw Coupling Hub (Part 4061677) Compatibility with Cummins Engines

The Jaw Coupling Hub, identified by part number 4061677 and manufactured by Cummins, is a critical component in the drivetrain system of several Cummins engine models. This part is integral to the proper functioning of the engine’s power transmission mechanism.

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines are part of Cummins’ QSK series, which are known for their robust design and high performance in various industrial applications. The Jaw Coupling Hub (4061677) is specifically engineered to fit these models, ensuring seamless power transfer from the engine to the drivetrain. Its design allows for precise alignment and secure connection, minimizing the risk of power loss or mechanical failure.

QSK60G

The QSK60G engine is another variant in the Cummins QSK series, designed for heavy-duty applications. The Jaw Coupling Hub (4061677) is compatible with this engine, providing the necessary durability and strength to handle the demanding conditions these engines often encounter. This part’s robust construction ensures that it can withstand the high torque and rotational forces typical of these heavy-duty engines.

QSK78 CM500

The QSK78 CM500 engine is a high-output variant in the Cummins QSK series, designed for applications requiring substantial power. The Jaw Coupling Hub (4061677) is engineered to fit this engine, ensuring that it can handle the increased power output and torque. Its design facilitates efficient power transmission, contributing to the overall performance and reliability of the engine.

Role of Part 4061677 Jaw Coupling Hub in Engine Systems

The part 4061677 Jaw Coupling Hub is an essential component in the synchronization and efficient operation of various engine systems. Its primary function is to connect and allow rotational movement between two shafts while accommodating minor misalignments. This feature is particularly beneficial in high-precision engine components where exact alignment might be challenging to maintain.

In the context of the Fuel Injection Pump, the Jaw Coupling Hub ensures smooth and consistent power transmission from the engine’s crankshaft to the pump. This consistent transmission is vital for the precise delivery of fuel into the combustion chamber, directly influencing the engine’s performance and efficiency.

When integrated with the Fuel Pump system, the Jaw Coupling Hub facilitates the transfer of rotational energy needed to drive the pump. This energy transfer is fundamental for maintaining the required fuel pressure within the system, ensuring that the engine receives a steady fuel supply under varying operational conditions.

Within the broader Fuel System, the Jaw Coupling Hub plays a supportive role by ensuring that all moving parts are synchronized. This synchronization is key to preventing fuel delivery inconsistencies, which could lead to engine misfires or inefficient combustion.

In systems utilizing a Gear Fuel Pump, the Jaw Coupling Hub is instrumental in transmitting the necessary torque from the engine to the pump gears. This transmission ensures that the gears operate efficiently, maintaining the desired fuel flow and pressure.

For any Pump within the engine system, whether it be for fuel, oil, or coolant, the Jaw Coupling Hub provides a reliable connection that can withstand the operational stresses and vibrations inherent in engine environments. This reliability is essential for the longevity and performance of the pump.

Conclusion

In summary, the Cummins 4061677 Jaw Coupling Hub is a versatile and essential component that fits seamlessly with the QSK45 CM500, QSK60 CM500, QSK60G, and QSK78 CM500 engines, ensuring optimal performance and durability across various industrial applications. Its role in engine systems is pivotal, providing a robust and flexible connection between rotating shafts that ensures the seamless operation of engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.