This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

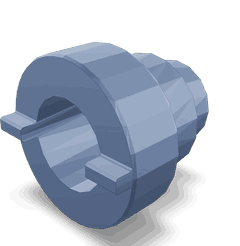

The 4910394 Jaw Coupling Hub, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces this coupling hub to enhance the efficiency and reliability of truck drivetrains. The Jaw Coupling Hub is integral to the smooth operation of trucks, facilitating the transmission of torque and accommodating misalignment between shafts.

Basic Concepts of Jaw Coupling Hubs

A Jaw Coupling Hub is a type of mechanical coupling that connects two shafts, allowing them to transmit torque while accommodating minor misalignments. It consists of two hubs with interlocking “jaws” that grip each other, providing a flexible yet robust connection. The fundamental principle behind jaw couplings is their ability to allow for angular, parallel, and axial misalignment, which is common in dynamic mechanical systems 1.

Purpose of the 4910394 Jaw Coupling Hub

The 4910394 Jaw Coupling Hub serves a vital role in the operation of a truck by transmitting torque between the engine and the transmission or between other components within the drivetrain. It is designed to handle significant torque loads while accommodating misalignments that may occur due to thermal expansion, wear, or other factors. This capability ensures that the drivetrain operates smoothly and efficiently, reducing the risk of mechanical failure 2.

Key Features

The 4910394 Jaw Coupling Hub is characterized by several key features that enhance its performance and durability. Its design incorporates precision-machined jaws that provide a secure grip, ensuring efficient torque transmission. The hub is constructed from high-strength materials, typically alloys, which offer resistance to wear and corrosion. Additionally, the coupling hub may feature lubrication points to reduce friction and extend service life 3.

Benefits

The advantages of using the 4910394 Jaw Coupling Hub include improved efficiency in torque transmission, reduced maintenance requirements due to its robust design, and enhanced reliability in truck operations. The ability to accommodate misalignment helps prevent additional stress on connected components, leading to a longer service life for the entire drivetrain.

Installation Considerations

When installing the 4910394, it is important to follow guidelines to ensure proper function. This includes achieving precise alignment between the shafts to prevent undue stress on the coupling. Torque specifications provided by the manufacturer should be adhered to during installation to ensure the jaws are securely fastened. Preparatory steps may involve cleaning the shafts and inspecting them for any damage or irregularities.

Troubleshooting Common Issues

Common problems associated with Jaw Coupling Hubs include excessive wear, misalignment, or failure to transmit torque effectively. Troubleshooting steps may involve inspecting the jaws for signs of wear or damage, ensuring proper alignment of the shafts, and checking for adequate lubrication. Addressing these issues promptly can help maintain the efficiency and reliability of the coupling hub.

Maintenance Tips

To ensure the longevity and optimal performance of the 4910394, routine maintenance practices are recommended. This includes regular inspection intervals to check for wear or damage, ensuring that lubrication points are adequately maintained, and following replacement guidelines when necessary. Proper maintenance can significantly extend the service life of the coupling hub and prevent unexpected failures.

Cummins: Manufacturer Overview

Cummins Inc. is a globally recognized manufacturer with a strong reputation in the automotive industry. The company has a history of producing high-quality components, including engines, transmissions, and coupling hubs. Cummins is committed to innovation and excellence, ensuring that their products meet the demanding requirements of commercial truck operations. Their dedication to quality and performance makes them a trusted name in the industry.

Jaw Coupling Hub (Part 4910394) in Cummins Engines

The Jaw Coupling Hub, identified by part number 4910394, is a critical component in the operation of certain Cummins engines, ensuring the efficient transfer of power between the engine and its driven components. This part is integral to the mechanical linkage system, facilitating smooth and reliable power transmission.

Application in Cummins KTA19GC Engines

In the Cummins KTA19GC engine, the Jaw Coupling Hub is designed to connect the engine’s output shaft to the driven equipment, such as generators or pumps. This coupling mechanism is essential for maintaining the integrity of the power transmission system, minimizing wear and vibration, and ensuring the longevity of the engine and its accessories.

Grouping of Cummins Engines

The Jaw Coupling Hub is compatible with a range of Cummins engines, including but not limited to:

- KTA19 Series: This includes engines like the KTA19GC, which are widely used in various industrial applications. The hub’s design ensures it fits seamlessly with the specific torque and rotational requirements of these engines.

- QSK Series: Certain models within the QSK series also utilize the Jaw Coupling Hub for their robust power transmission needs.

- QSC Series: Similar to the QSK series, the QSC series engines benefit from the reliable power transfer provided by this coupling hub.

The Jaw Coupling Hub’s design and material composition are tailored to withstand the high stresses and operational demands of these engines, ensuring consistent performance and reliability in demanding environments.

Role of Part 4910394 Jaw Coupling Hub in Engine Systems

The 4910394 Jaw Coupling Hub is an integral component in the efficient operation of various engine systems. It facilitates the seamless transfer of rotational force between the accessory W-W governor drive and the coupling, ensuring that the accessory operates in harmony with the engine’s rotational speed.

In the context of the fuel pump, the Jaw Coupling Hub plays a significant role by maintaining a consistent and reliable connection. This ensures that the fuel pump receives the necessary rotational force to function optimally, thereby contributing to the engine’s overall performance.

When integrated with the Woodward governor, the Jaw Coupling Hub ensures that the governor can accurately regulate the engine’s speed. This is achieved through the precise transmission of rotational motion, allowing the Woodward governor to make real-time adjustments based on the engine’s operational demands.

Overall, the 4910394 Jaw Coupling Hub is essential for the synchronized operation of these components, enhancing the engine’s efficiency and reliability.

Conclusion

The 4910394 Jaw Coupling Hub is a critical component in the operation of Cummins engines, ensuring efficient and reliable power transmission. Its design, featuring precision-machined jaws and high-strength materials, allows it to handle significant torque loads and accommodate misalignments. Proper installation, maintenance, and troubleshooting are essential to maximize the performance and longevity of this part. Cummins’ commitment to quality and innovation ensures that the Jaw Coupling Hub meets the demanding requirements of commercial truck operations, contributing to the overall efficiency and reliability of the drivetrain.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.