This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Fuel Supply Tube, identified by part number 2896837, is a critical component in the fuel system of heavy-duty trucks. Manufactured by Cummins Inc., a leader in the automotive industry, this part ensures efficient fuel delivery to the injectors, contributing to the overall performance and reliability of the engine 1.

Function and Operation

The Injector Fuel Supply Tube operates within the fuel injection system by facilitating the transfer of fuel from the fuel rail to the injector. This component ensures a consistent and precise fuel supply, which is vital for the combustion process. The tube’s design allows it to withstand high pressures and temperatures, maintaining fuel integrity as it travels from the rail to the injector nozzle 2.

Key Features

The Cummins Injector Fuel Supply Tube is engineered with several key features that enhance its performance and durability. Constructed from high-quality materials, the tube is resistant to corrosion and wear, ensuring longevity in demanding environments. Its precision-machined design guarantees a secure fit within the fuel system, minimizing the risk of leaks and ensuring optimal fuel flow. Additionally, the tube’s robust construction supports its function under the high-pressure conditions typical of heavy-duty engines 3.

Benefits

The Injector Fuel Supply Tube offers several advantages that contribute to the efficiency and reliability of the fuel system. By providing a consistent and precise fuel supply, it enhances engine performance and fuel economy. The tube’s durable construction ensures reliability even in challenging operating conditions, reducing the likelihood of fuel system failures. Furthermore, its design contributes to the overall efficiency of the fuel injection process, supporting the engine’s power output and responsiveness 4.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube is crucial for maintaining the integrity of the fuel system. It is designed to be compatible with Cummins engines and other relevant components within the fuel system. When installing this part, it is important to follow manufacturer guidelines to ensure a secure and proper fit, which is essential for optimal performance and safety 5.

Maintenance and Troubleshooting

Routine maintenance of the Injector Fuel Supply Tube is important for ensuring its continued performance and reliability. Regular inspections for signs of wear, corrosion, or leaks are recommended. In the event of fuel leaks or blockages, troubleshooting may involve checking for proper installation, inspecting connections for tightness, and ensuring there are no obstructions within the tube. Addressing these issues promptly can prevent more significant problems within the fuel system 6.

Safety Considerations

When working with the Injector Fuel Supply Tube, it is important to observe safety precautions and best practices. This includes proper handling to avoid damage to the tube, secure storage to prevent contamination or physical damage, and adherence to disposal procedures for any waste materials. Additionally, working within the fuel system requires awareness of the high-pressure and flammable nature of fuel, necessitating caution and adherence to safety protocols 7.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its high-quality engines and components. With a history of innovation and excellence, Cummins offers a wide range of products designed to meet the demands of various applications, from heavy-duty trucks to industrial equipment. The company’s reputation for reliability and performance is supported by its commitment to engineering excellence and customer satisfaction 8.

Compatibility

The Injector Fuel Supply Tube (2896837) is compatible with the Cummins QSK50 and CM2150 engines. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The part is engineered to fit seamlessly within the intricate fuel systems of these engines, ensuring that fuel is delivered precisely where it is needed 9.

Installation and Functionality

The installation of the Injector Fuel Supply Tube (2896837) is a straightforward process, designed to be compatible with the specific requirements of the QSK50, CM2150, and MCRS engines. This part plays a role in the overall functionality of the engine by facilitating the smooth and uninterrupted flow of fuel to the injectors. Its design and material are chosen to withstand the high pressures and temperatures encountered in these engines, ensuring longevity and reliability 10.

Importance of the Part

The Injector Fuel Supply Tube (2896837) is a component in the fuel delivery system of the Cummins QSK50, CM2150, and MCRS engines. Its proper installation and maintenance are important for the engines’ performance, efficiency, and durability. This part’s compatibility with these engines underscores its importance in maintaining the high standards of performance expected from Cummins engines 11.

Role in Engine Systems

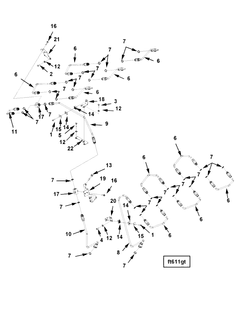

The Injector Fuel Supply Tube, designated as part 2896837, is integral to the efficient operation of fuel supply systems within engine assemblies. This component is responsible for delivering pressurized fuel from the fuel supply plumbing to the injectors.

In conjunction with the injector kit, the Injector Fuel Supply Tube ensures a consistent and reliable fuel flow to each injector. This is important for maintaining the precise fuel-air mixture required for optimal engine performance. The tube’s design allows it to interface seamlessly with the injector kit, facilitating a secure and leak-proof connection.

The integration of the Injector Fuel Supply Tube within the overall plumbing system is designed to minimize fuel line restrictions and ensure uniform fuel distribution. This component works in harmony with the fuel supply plumbing to maintain system integrity and efficiency.

Furthermore, the Injector Fuel Supply Tube plays a role in the fuel system’s ability to respond to varying engine demands. By providing a dedicated pathway for fuel, it supports the dynamic adjustments made by the injectors in response to throttle inputs and engine load changes.

Conclusion

In summary, the Injector Fuel Supply Tube is an element in the fuel delivery process, ensuring that each injector receives the necessary fuel supply for consistent and efficient engine operation. Its design, durability, and compatibility with Cummins engines make it a vital component for maintaining engine performance and reliability.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C. Bulletin Number 6310310.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C. Bulletin Number 6310310.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C. Bulletin Number 6310310.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C. Bulletin Number 6310310.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C. Bulletin Number 6310310.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C. Bulletin Number 6310310.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for GTA855GCE CMEICS N110C. Bulletin Number 6310310.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.