This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Fuel Supply Tube, part number 2896918, is a vital component in the fuel system of heavy-duty trucks. It ensures efficient fuel delivery from the tank to the injectors, contributing to engine performance and efficiency. Designed for Cummins engines, this part is integral to their reliability and power.

Function and Operation

This Cummins part facilitates the transfer of fuel from the tank to the injectors, maintaining consistent fuel pressure and a steady supply. This ensures precise operation of fuel injectors, optimizing combustion efficiency and enhancing engine performance. The tube is engineered to withstand high pressures and temperatures, ensuring reliable operation under various conditions.

Key Features

The Injector Fuel Supply Tube is known for its durable construction and precise engineering. Made from high-quality materials, it resists corrosion and wear, ensuring longevity. Its design includes smooth internal surfaces to minimize fuel turbulence and precise fittings for secure connections, contributing to the efficiency and reliability of the fuel delivery system.

Benefits

Using the Injector Fuel Supply Tube offers several benefits. It improves fuel efficiency by ensuring a consistent and pressurized fuel supply to the injectors, enhancing engine performance through efficient combustion. Its durable construction reduces the risk of fuel leaks, which can be hazardous and lead to engine damage. The robust design also increases the overall durability of the fuel system, reducing the need for frequent replacements and maintenance.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube is crucial for its effective operation. It requires specific tools and adherence to manufacturer guidelines for a secure and leak-free connection. The tube is compatible with various Cummins engine models, designed to fit seamlessly within the existing fuel system. Specific installation requirements may vary depending on the engine model, so consulting the manufacturer’s guidelines for detailed instructions is important.

Maintenance and Troubleshooting

Regular maintenance is recommended to ensure the long-term performance of the Injector Fuel Supply Tube. This includes periodic inspections for signs of wear, corrosion, or leaks. Common issues such as fuel leaks or blockages can often be traced back to improper installation or wear and tear. Troubleshooting these problems may involve checking connections, replacing worn components, or cleaning the tube to remove any obstructions. Regular maintenance practices help in identifying potential issues early, ensuring the continued reliability of the fuel system.

Safety Considerations

When working with the Injector Fuel Supply Tube, observing safety considerations is important. Handling fuel system components requires caution due to the flammable nature of fuel. Ensuring proper ventilation when working on the fuel system is crucial to prevent the accumulation of fuel vapors. Additionally, following manufacturer guidelines for installation and maintenance helps in preventing accidents and ensuring safe operation of the vehicle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and customer satisfaction in the automotive industry. The company is committed to advancing technology in engine design and fuel systems, ensuring that their components, like the Injector Fuel Supply Tube, meet the highest standards of performance and reliability 1.

Compatibility with Cummins Engines

The Injector Fuel Supply Tube (Part 2896918) is compatible with various Cummins engine models, including the QSK60, CM850, and MCRS series. This compatibility ensures that these engines can operate efficiently and reliably under various conditions 2.

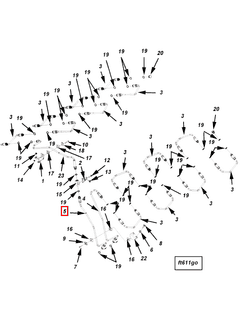

Integration with the Injector Kit

When installed, the Injector Fuel Supply Tube connects directly to the Injector Kit. This tube facilitates the transfer of fuel from the main fuel rail to the individual injectors. The precise fit and seal provided by this tube are important for maintaining consistent fuel pressure and flow, which are necessary for the injectors to atomize fuel effectively. This atomization is vital for proper combustion within the engine cylinders 3.

Role in Fuel Plumbing

In the context of fuel plumbing, the Injector Fuel Supply Tube acts as a critical conduit. It ensures that fuel is delivered smoothly and without restriction from the fuel rail to each injector. The tube must be correctly aligned and secured to prevent leaks and maintain system integrity. Proper installation and maintenance of this tube are important for the overall efficiency of the fuel delivery system 4.

Ensuring Reliable Fuel Delivery

The Injector Fuel Supply Tube plays a significant role in the reliability of the fuel delivery system. It must withstand the pressures and temperatures within the engine compartment while providing a consistent fuel path. Any malfunction or blockage in this tube can lead to uneven fuel distribution, affecting engine performance and efficiency. Regular inspection and maintenance of this component are recommended to prevent such issues.

Conclusion

The Injector Fuel Supply Tube (Part 2896918) is a key element in the fuel delivery system, working seamlessly with the injector kit and fuel plumbing to ensure optimal engine performance. Its durable construction, precise engineering, and compatibility with various Cummins engine models make it an essential component for maintaining engine efficiency and reliability.

-

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems (SAE International, 2020).

↩ -

Thorsten Boger and Willard Cutler, Reducing Particulate Emissions in Gasoline Engines (SAE International, 2018).

↩ -

Deanna Sclar, Auto Repair for Dummies: 2nd Edition (For Dummies, 2008).

↩ -

Zhiyu Han, Simulation and Optimization of Internal Combustion Engines (SAE International, 2022).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.