This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

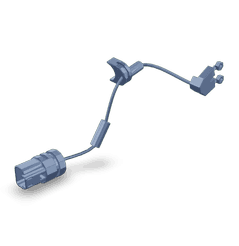

The Cummins Injector Wiring Harness, part number 2897004, is a critical component in the operation of heavy-duty trucks. Cummins, a leader in diesel engine technology, designs this harness to ensure efficient and reliable fuel injection system performance. The harness is integral to the overall functionality of the truck’s engine, facilitating the precise delivery of fuel which is essential for optimal engine operation.

Basic Concepts

Injector wiring harnesses are fundamental to the fuel injection system of diesel engines. They serve as the conduit for electrical signals and power between the engine control unit (ECU) and the fuel injectors. This communication is essential for the ECU to control the timing and quantity of fuel injected into the engine cylinders, thereby optimizing combustion efficiency and performance 1.

Purpose and Functionality

The Injector Wiring Harness 2897004 plays a significant role in the operation of heavy-duty trucks by transmitting electrical signals and power to the fuel injectors. This ensures precise fuel delivery, which is critical for maintaining engine efficiency and performance. The harness allows the ECU to monitor and adjust fuel injection parameters in real-time, enhancing the engine’s responsiveness and efficiency.

Key Features

The Injector Wiring Harness 2897004 is designed with several key features to ensure reliable performance in demanding environments. Its durable construction and use of corrosion-resistant materials make it suitable for withstanding the harsh conditions often encountered in heavy-duty truck applications. The precise engineering of the harness ensures that it meets the stringent requirements for electrical conductivity and signal integrity, contributing to the overall reliability of the fuel injection system.

Benefits

The use of the Injector Wiring Harness 2897004 offers several benefits. It contributes to improved fuel efficiency by enabling precise fuel delivery, which optimizes combustion. This results in enhanced engine performance and reduced emissions, as the harness ensures that the fuel injection process is as efficient as possible. The reliable operation of the harness is also instrumental in maintaining the longevity and performance of the engine.

Troubleshooting and Maintenance

Common issues with injector wiring harnesses may include electrical faults or corrosion. Regular inspection and maintenance are recommended to identify and address these issues promptly. Ensuring that the harness is properly routed, secured, and protected from environmental factors can help prevent damage and ensure optimal performance. Additionally, using appropriate cleaning agents and techniques can help maintain the integrity of the harness over time.

Installation Considerations

When installing the Injector Wiring Harness 2897004, it is important to consider proper routing to avoid interference with other components and to minimize the risk of damage. Securement of the harness is also critical to prevent movement that could lead to wear or disconnection. Protection from environmental factors, such as moisture and extreme temperatures, is necessary to maintain the harness’s performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the commercial vehicle industry. The company’s product offerings include a wide range of engines and components designed to meet the demanding requirements of heavy-duty applications.

Cummins Injector Wiring Harness 2897004 Compatibility

The Cummins Injector Wiring Harness part number 2897004 is designed to integrate seamlessly with a variety of Cummins engines, ensuring reliable electrical connections to the injectors. This wiring harness is crucial for maintaining the performance and efficiency of the engine by ensuring that the injectors receive the correct electrical signals.

QST30 and CM2350 Engines

The QST30 and CM2350 engines are part of the Cummins QSX and CMM series, respectively. These engines are known for their robust design and are commonly used in heavy-duty applications such as trucks and industrial machinery. The injector wiring harness 2897004 is specifically engineered to fit these engines, providing a secure and durable connection that can withstand the rigors of continuous operation.

T101 Engine

The T101 engine is another member of the Cummins lineup, often utilized in various industrial and marine applications. The injector wiring harness 2897004 is compatible with the T101 engine, ensuring that the electrical pathways to the injectors are properly maintained. This compatibility is essential for the engine’s optimal performance, as it guarantees that the injectors operate correctly, contributing to efficient fuel delivery and combustion.

Grouping for Compatibility

The injector wiring harness 2897004 is designed to be versatile, fitting into multiple engine models within the Cummins range. This compatibility is particularly beneficial for fleets and operators who use a variety of Cummins engines, as it allows for a standardized approach to maintenance and repair. By using a single part number for multiple engines, the process of sourcing and installing the wiring harness becomes more streamlined, reducing downtime and maintenance costs.

Role of Part 2897004 Injector Wiring Harness in Engine Systems

The Injector Wiring Harness (Part 2897004) is integral to the efficient operation of various engine components. It serves as the vital electrical conduit that connects the fuel injectors to the engine’s control unit, ensuring precise fuel delivery and timing.

Integration with Key Components

-

Fuel Injectors: The wiring harness directly interfaces with each fuel injector, providing the necessary electrical signals for operation. This ensures that fuel is delivered in the correct quantity and at the precise moment, optimizing combustion efficiency and performance.

-

Engine Control Unit (ECU): The harness transmits data between the fuel injectors and the ECU. This communication allows the ECU to monitor and adjust fuel delivery based on real-time engine conditions, enhancing overall engine performance and fuel economy.

-

Camshaft and Gear: Although the camshaft and gear are mechanical components responsible for valve timing, the Injector Wiring Harness plays a supporting role by ensuring that fuel injection is synchronized with the camshaft’s position. This synchronization is essential for optimal engine performance and smooth operation.

-

Fuel Manifold: The harness also connects to the fuel manifold, which distributes fuel to the injectors. Proper wiring ensures that the fuel manifold receives consistent electrical signals, allowing for uniform fuel distribution across all cylinders.

-

Performance Parts: In high-performance engine setups, the Injector Wiring Harness must be capable of handling increased electrical demands. It ensures that upgraded injectors and other performance parts receive the necessary power and signals to function at their peak, contributing to enhanced engine output and reliability.

Conclusion

In summary, the Injector Wiring Harness (Part 2897004) is a fundamental component that facilitates the seamless interaction between the engine’s electrical and mechanical systems, ultimately contributing to improved performance and efficiency. Its role in ensuring precise fuel delivery, synchronization with engine components, and compatibility with various Cummins engines makes it an indispensable part of the fuel injection system.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.