This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Injector Cup, identified by part number 3018813, is a component integral to the operation of heavy-duty trucks equipped with Cummins engines. This part is designed to facilitate the proper functioning of the fuel injection system by ensuring a secure and leak-free connection between the fuel injector and the cylinder head. Its role is significant in maintaining the overall efficiency and reliability of the engine 3.

Basic Concepts and Functionality

Injector cups are fundamental components in diesel engine fuel systems. They serve as a seal and support structure for the fuel injector within the cylinder head. The injector cup operates by providing a precise fit and seal that allows the injector to function correctly under high pressure and temperature conditions. It ensures that fuel is delivered efficiently to the combustion chamber without leaks, which is vital for optimal engine performance 4.

Purpose of the Injector Cup

The Cummins Injector Cup plays a role in the operation of a truck by sealing the fuel injector within the cylinder head and maintaining the integrity of the fuel system. It ensures that fuel is delivered under pressure to the combustion chamber without leakage, which is crucial for efficient combustion and engine performance. By providing a secure and reliable seal, the injector cup helps to prevent fuel from entering the engine’s lubrication system, which could lead to contamination and reduced engine life 1.

Key Features

The Cummins Injector Cup is characterized by several key features that contribute to its effectiveness and durability. These include a robust construction designed to withstand the high pressures and temperatures of diesel engine operation, precise engineering to ensure a perfect fit with the fuel injector and cylinder head, and compatibility with specific Cummins engine models. These features collectively enhance the reliability and performance of the fuel injection system 2.

Benefits

The Cummins Injector Cup offers several benefits that contribute to improved engine performance and efficiency. These include enhanced fuel delivery precision, which leads to more efficient combustion and better engine performance. Additionally, the cup’s design helps to reduce the risk of fuel leaks, which can lead to engine damage and decreased efficiency. The durable construction of the injector cup also contributes to its longevity, reducing the need for frequent replacements 3.

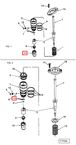

Installation Process

Proper installation of the Cummins Injector Cup is critical for ensuring the component’s effectiveness and the engine’s overall performance. The installation process involves several steps, including preparing the cylinder head for the injector cup, ensuring the cup is correctly aligned with the fuel injector, and securing it in place. It is important to follow manufacturer guidelines and best practices to ensure a proper seal and prevent damage to the component or engine 4.

Common Issues and Troubleshooting

Injector cups can encounter issues such as leaks or failures, which may affect engine performance. Common problems include improper sealing, which can lead to fuel leaks, and cup degradation over time due to high temperatures and pressures. Troubleshooting these issues involves inspecting the injector cup for signs of wear or damage, ensuring it is correctly installed, and replacing it if necessary to restore engine performance and fuel system integrity 1.

Maintenance Tips

To ensure the longevity and reliability of the Cummins Injector Cup, routine maintenance practices are recommended. These include regular inspections for signs of wear or damage, following manufacturer-recommended replacement intervals, and ensuring the injector cup is correctly installed and sealed. Adhering to these maintenance tips can help prevent common issues and ensure the fuel injection system operates efficiently 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industries. The company offers a wide range of products and services designed to meet the needs of various applications, from on-highway to off-highway and stationary power solutions.

Understanding the Role of Part 3018813 Injector Cup in Engine Systems

The injector cup, specifically part 3018813, is an integral component within the fuel injection system of an engine. Its primary function is to provide a secure and sealed environment for the injector to operate efficiently. This ensures that the fuel is delivered precisely and consistently into the combustion chamber 3.

Integration with Injector and Fuel Delivery System

Part 3018813 works in conjunction with the injector to maintain the integrity of the fuel path. It helps in withstanding the high pressures and temperatures generated during the injection process. The injector-pressure-time delivery is optimized when the injector cup is in good condition, ensuring that the fuel is atomized correctly for efficient combustion 4.

Contribution to Liner Kit Performance

When integrated into a liner kit, the injector cup plays a significant role in enhancing the overall performance of the engine. The liner kit is designed to improve the durability and efficiency of the engine components. The injector cup, by ensuring a proper seal and consistent fuel delivery, contributes to the longevity and reliability of the liner kit components 1.

Impact on Engine Performance Parts

In the context of performance parts, the injector cup is often overlooked but is essential for maintaining the desired performance levels. High-performance engines demand precise fuel delivery to achieve optimal power output and efficiency. Part 3018813 ensures that the injector operates within specified parameters, thereby supporting the performance goals of the engine 2.

Ensuring Component Reliability

The reliability of engine components is significantly influenced by the condition of the injector cup. A well-maintained injector cup prevents leaks and ensures that the fuel injection process is consistent. This consistency is vital for the reliable operation of other engine components, including the injector itself and the overall fuel delivery system 3.

Conclusion

In summary, part 3018813 Injector Cup is a key component that supports the efficient and reliable operation of the fuel injection system. Its role in maintaining seals, optimizing fuel delivery, and contributing to the performance of engine components makes it an essential part of any engine system 4.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ ↩ ↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ ↩ ↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ ↩ ↩ ↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.