This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

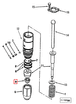

The Cummins 3018814 Injector Cup is a component designed for use in diesel engines, particularly those found in heavy-duty trucks. Its purpose is to facilitate the proper functioning of the fuel injection system. This part is significant in ensuring the efficient and reliable operation of diesel engines by contributing to fuel delivery and combustion processes 1.

Basic Concepts and Functionality

Injector cups are integral to diesel engine fuel injection systems. They serve as a seal between the injector and the cylinder head, ensuring that fuel is delivered precisely into the combustion chamber. The injector cup operates by withstanding high pressures and temperatures, maintaining the integrity of the fuel injection process. It plays a role in containing the fuel within the combustion chamber and ensuring that it mixes effectively with air for combustion 2.

Purpose of the Injector Cup

The Cummins 3018814 Injector Cup ensures the proper sealing and delivery of fuel into the combustion chamber. This contributes to fuel efficiency by allowing for precise fuel atomization and combustion. It also enhances engine performance by maintaining consistent fuel delivery under varying operating conditions. Additionally, the injector cup contributes to the overall reliability of the engine by withstanding the harsh environment within the combustion chamber.

Key Features

The Cummins 3018814 Injector Cup is characterized by its robust design and the materials used in its construction. It is typically made from high-strength steel or other durable alloys, which provide resistance to wear and corrosion. The design of the injector cup includes features that enhance its sealing capabilities and ensure it can withstand the high pressures and temperatures within the engine. These characteristics contribute to its performance and durability.

Benefits

Using the Cummins 3018814 Injector Cup offers several benefits. It contributes to improved fuel atomization, which enhances combustion efficiency and can lead to better fuel economy. Reduced engine wear is another advantage, as the injector cup’s durable construction helps protect engine components from the stresses of fuel injection. Enhanced engine longevity is also a benefit, as the reliable operation of the injector cup supports the overall durability of the engine.

Installation and Compatibility

Proper installation of the Cummins 3018814 Injector Cup is important for ensuring its effective operation. Installation procedures typically involve careful alignment with the cylinder head and injector, ensuring a secure and leak-free seal. Compatibility with various Cummins engine models is a consideration, as the injector cup must be suited to the specific engine design and fuel injection system.

Troubleshooting and Maintenance

Common issues associated with injector cups can include leaks, wear, and failure to seal properly. Troubleshooting techniques may involve inspecting the injector cup for signs of damage or wear, checking the seal integrity, and ensuring proper installation. Maintenance practices to ensure optimal performance and longevity of the injector cup include regular inspection and replacement as necessary, following manufacturer guidelines for maintenance intervals.

Performance Enhancements

The Cummins 3018814 Injector Cup contributes to overall engine performance in several ways. It plays a role in achieving consistent power output by ensuring reliable fuel delivery. Improved fuel efficiency is another benefit, as efficient fuel atomization and combustion lead to better fuel economy. Additionally, the injector cup can contribute to emissions reduction by supporting clean and efficient combustion processes.

Cummins Overview

Cummins Inc. is a well-established manufacturer of diesel engines and related components, with a history of innovation and quality in the industry. The company’s reputation for producing reliable and high-performance engine parts is supported by its commitment to engineering excellence and customer satisfaction. Cummins’ extensive product line and global presence underscore its position as a leader in the diesel engine market.

Cummins Injector Cup 3018814 Compatibility

The Cummins Injector Cup, part number 3018814, is a component in the fuel injection system of several diesel engines. This part is designed to fit seamlessly with the NH/NT 855 engine series, ensuring optimal performance and reliability.

NH/NT 855 Engine Series

The NH/NT 855 engine series is renowned for its robust design and efficiency. The injector cup 3018814 is engineered to work with these engines, providing precise fuel delivery and maintaining the high standards of performance expected from Cummins engines.

Integration and Functionality

When installed in the NH/NT 855 engines, the injector cup 3018814 plays a pivotal role in the fuel injection process. It ensures that fuel is delivered to the combustion chamber at the correct pressure and timing, which is essential for the engine’s efficiency and power output. The design of the injector cup allows for a tight seal, preventing fuel leaks and ensuring that the engine operates smoothly.

Precision and Durability

Cummins is known for its precision engineering, and the injector cup 3018814 is no exception. It is manufactured to exacting specifications, ensuring that it fits perfectly with the NH/NT 855 engines. The durability of this part is another key factor, as it is built to withstand the high pressures and temperatures found within the engine, providing long-lasting performance.

Installation and Maintenance

Installing the injector cup 3018814 in the NH/NT 855 engines is a straightforward process, thanks to its precise fit. Regular maintenance of this component is crucial to ensure that the engine continues to perform at its best. Cummins provides detailed guidelines for the installation and maintenance of this part, ensuring that it is handled correctly by technicians and mechanics.

Compatibility and Usage

The injector cup 3018814 is specifically designed for use with the NH/NT 855 engines, making it an essential part for anyone working with these engines. Its compatibility with this engine series ensures that users can rely on it for consistent and reliable performance.

Understanding the Role of Part 3018814 Injector Cup in Engine Systems

The injector cup, identified by part number 3018814, is a component within the fuel injection system of an engine. Its primary function is to provide a secure and sealed environment for the injector within the cylinder head. This ensures that fuel is delivered precisely and efficiently to the combustion chamber.

Integration with Injector Systems

When the injector is activated, it sprays fuel into the combustion chamber. The injector cup plays a significant role in this process by maintaining the integrity of the fuel path. It prevents fuel from leaking into the cylinder head, which could lead to performance issues and potential engine damage. The cup’s design allows for optimal fuel atomization, enhancing the injector-pressure-time delivery. This results in more efficient combustion and improved engine performance.

Contribution to Performance Parts

In the realm of performance parts, the injector cup is often overlooked but is equally important as the injector itself. High-performance engines demand components that can withstand greater pressures and temperatures. The 3018814 injector cup is engineered to meet these demands, ensuring that the injector operates within its specified parameters even under extreme conditions. This reliability is vital for maintaining the overall performance and longevity of the engine.

Ensuring Precise Fuel Delivery

The precision of fuel delivery is paramount in modern engine systems. The injector cup contributes to this by providing a consistent and sealed interface for the injector. This consistency is crucial for the injector to perform its function accurately, delivering the correct amount of fuel at the right time. Any deviation in this process can lead to inefficiencies, reduced power output, and increased emissions.

Role in Engine Longevity

Beyond performance, the injector cup also plays a part in the longevity of the engine. By ensuring a secure fit and seal, it prevents contaminants from entering the fuel system, which can cause wear and tear on the injector and other components. This protective role helps in maintaining the engine’s health over time, reducing the need for frequent repairs and replacements.

Conclusion

The Cummins 3018814 Injector Cup is a fundamental component in the fuel injection system, contributing to efficient fuel delivery, enhanced performance, and engine longevity. Its role, though often behind the scenes, is indispensable in the operation of modern engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.