This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3076050 Fuel Injector is a component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by ensuring efficient fuel delivery and combustion. This injector is part of Cummins Inc.’s lineup of high-performance automotive components, known for their reliability and efficiency in demanding applications 2.

Basic Concepts of Fuel Injectors

Fuel injectors are devices used in internal combustion engines to deliver fuel into the combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air before ignition. This process enhances combustion efficiency, leading to better engine performance and fuel economy. Fuel injectors are controlled electronically, allowing for precise fuel delivery based on engine requirements 4.

Purpose of the Cummins 3076050 Fuel Injector

The Cummins 3076050 Fuel Injector is specifically designed to enhance the fuel delivery system in trucks. It ensures that fuel is delivered at the right time and in the correct amount, optimizing combustion efficiency. This injector contributes to smoother engine operation, increased power output, and improved fuel economy 3.

Key Features

The Cummins 3076050 Fuel Injector features a robust design that includes high-quality materials resistant to wear and corrosion. It incorporates advanced technological features such as precise fuel metering and electronic control, which enhance its performance. The injector’s design allows for efficient fuel atomization, ensuring optimal combustion 1.

Benefits

The Cummins 3076050 Fuel Injector offers several benefits, including improved fuel efficiency, enhanced engine performance, and reduced emissions. By ensuring precise fuel delivery, it helps in achieving better combustion, which translates to increased power output and fuel savings. Additionally, the efficient combustion process results in lower emissions, contributing to a reduced environmental impact 2.

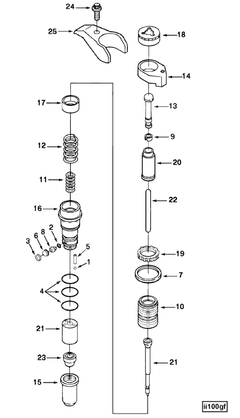

Installation and Integration

Proper installation of the Cummins 3076050 Fuel Injector involves several steps to ensure it integrates seamlessly with the truck’s fuel system. This includes preparing the fuel system, aligning the injector correctly, and ensuring all connections are secure. Following the manufacturer’s guidelines during installation is important to maintain the injector’s performance and longevity 4.

Performance and Efficiency

The Cummins 3076050 Fuel Injector contributes to the overall performance and efficiency of the truck. It plays a role in achieving measurable improvements in fuel economy and power output. The precise fuel delivery and efficient combustion facilitated by this injector result in a more responsive and powerful engine, enhancing the driving experience 3.

Troubleshooting and Maintenance

Common issues with the Cummins 3076050 Fuel Injector may include clogged nozzles or electronic malfunctions. Diagnostic procedures involve checking for proper fuel delivery and electronic signals. Regular maintenance, such as cleaning the injector and inspecting electrical connections, is important to ensure longevity and optimal performance 4.

Comparative Analysis

When compared to other fuel injectors in the market, the Cummins 3076050 Fuel Injector stands out due to its advanced features and high performance. Its precise fuel metering and robust design provide unique advantages, making it a preferred choice for commercial truck applications 1.

Environmental Impact

The Cummins 3076050 Fuel Injector helps in reducing the environmental impact of truck operations. By ensuring efficient fuel combustion and lower emissions, it contributes to a cleaner environment. The advanced technology incorporated in this injector plays a role in minimizing the carbon footprint of commercial trucks 2.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the industry for producing high-quality automotive components. The company is committed to innovation and quality, ensuring that its products, including the Cummins 3076050 Fuel Injector, meet the highest standards of performance and reliability 3.

Cummins Fuel Injector 3076050 Compatibility

The Cummins fuel injector part number 3076050 is a critical component in the fuel delivery system of various Cummins engines. This part is designed to ensure precise fuel atomization and delivery, which is essential for optimal engine performance and efficiency. Below is a detailed description of the compatibility of this fuel injector with specific Cummins engines.

N14 Mechanical Engine

The Cummins N14 Mechanical engine is a robust and reliable engine widely used in heavy-duty applications. The fuel injector 3076050 is specifically engineered to fit seamlessly into the N14 Mechanical engine. This compatibility ensures that the injector can handle the high-pressure fuel requirements of the engine, providing consistent fuel delivery and contributing to the engine’s overall performance and longevity.

Group Compatibility

The Cummins fuel injector 3076050 is also compatible with other engines within the same engine family as the N14 Mechanical. These engines share similar design characteristics and operational parameters, making the injector a versatile component across multiple models. Ensuring that the injector fits correctly within these engines is crucial for maintaining the engine’s efficiency and reliability.

By using the Cummins fuel injector 3076050 in the N14 Mechanical engine and other compatible engines, users can expect enhanced fuel efficiency, reduced emissions, and improved engine performance. This compatibility highlights the importance of using genuine Cummins parts to maintain the integrity and functionality of the engine 3.

Role of Part 3076050 Fuel Injector in Engine Systems

The part 3076050 Fuel Injector is an essential component within the fuel delivery system of an engine. Its primary function is to precisely deliver fuel into the combustion chamber at the correct time and in the right amount. This ensures optimal fuel-air mixture, which is vital for efficient combustion and engine performance 4.

Interaction with Other Components

-

Fuel Rail: The fuel injector is typically mounted on the fuel rail, which distributes pressurized fuel to each injector. The injector receives a steady supply of fuel from the rail, allowing it to deliver precise amounts as commanded by the engine control unit (ECU).

-

Engine Control Unit (ECU): The ECU monitors various engine parameters such as engine speed, load, and air intake. Based on this data, it sends signals to the fuel injector to open and close at specific intervals, ensuring the correct fuel delivery for the current operating conditions.

-

Intake Manifold: After the fuel is injected, it mixes with the air in the intake manifold before entering the combustion chamber. The design of the intake manifold affects how the fuel-air mixture is distributed to each cylinder.

-

Combustion Chamber: The fuel injector sprays fuel directly into the combustion chamber, where it mixes with air and is ignited by the spark plug. The efficiency of this process directly impacts engine power, fuel economy, and emissions.

-

Oxygen Sensor: Located in the exhaust system, the oxygen sensor measures the amount of oxygen in the exhaust to determine the air-fuel ratio. This data is sent back to the ECU, which adjusts the fuel injector’s operation to maintain optimal combustion.

-

Throttle Body: The throttle body regulates the amount of air entering the engine. The fuel injector must coordinate with the throttle body to maintain the correct air-fuel ratio as the throttle position changes.

-

Mass Airflow Sensor (MAF): The MAF sensor measures the amount of air entering the engine. This information is critical for the ECU to calculate the appropriate amount of fuel to be injected by the injector.

-

Fuel Pump: The fuel pump pressurizes the fuel in the fuel tank and sends it through the fuel lines to the fuel rail. Consistent fuel pressure is necessary for the injector to operate correctly.

-

Fuel Filter: The fuel filter removes impurities from the fuel before it reaches the injector. Clean fuel ensures the injector operates efficiently and prevents clogging.

-

Spark Plugs: The spark plugs ignite the fuel-air mixture in the combustion chamber. The timing of the fuel injection must be synchronized with the spark plug firing for optimal combustion.

In summary, the part 3076050 Fuel Injector works in concert with various engine components to ensure precise fuel delivery, which is fundamental for engine performance, efficiency, and emissions control 4.

Conclusion

The Cummins 3076050 Fuel Injector is a critical component in the fuel delivery system of commercial trucks, designed to enhance engine performance, fuel efficiency, and reduce emissions. Its advanced features, robust design, and precise fuel metering make it a preferred choice for demanding applications. Proper installation, regular maintenance, and the use of genuine Cummins parts are essential to ensure optimal performance and longevity of this injector.

-

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ ↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ ↩ ↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ ↩ ↩ ↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ ↩ ↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.