This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3423040 Injector Cup is a component designed for use in heavy-duty trucks, specifically within the fuel injection system. Its purpose is to ensure the proper functioning of the fuel injectors by maintaining fuel pressure and providing a secure seal. This component is significant in the operation of heavy-duty trucks as it contributes to the overall efficiency and reliability of the engine.

Basic Concepts of Injector Cups

An injector cup, also known as an injector sleeve, is a cylindrical component that houses the fuel injector within the engine cylinder head. Its primary function is to create a seal that prevents fuel from leaking into the cylinder and to maintain the integrity of the fuel injection system. The injector cup interacts closely with the fuel injector, cylinder head, and other fuel system components to ensure efficient fuel delivery and combustion 1.

Purpose of the Cummins 3423040 Injector Cup

The Cummins 3423040 Injector Cup plays a role in the operation of a truck’s engine by maintaining fuel pressure and sealing the injector. It ensures that fuel is delivered at the correct pressure and timing, which is vital for optimal engine performance. Additionally, the injector cup prevents fuel leaks, which could lead to engine damage or reduced efficiency 2.

Key Features

The Cummins 3423040 Injector Cup is constructed from high-quality materials, typically including heat-treated steel, which provides durability and resistance to the high pressures and temperatures within the engine. Its design includes precise machining to ensure a proper fit within the cylinder head and a smooth surface to facilitate a secure seal with the fuel injector. Unique characteristics such as enhanced sealing properties and resistance to wear and corrosion further contribute to its performance 3.

Benefits of Using the Cummins 3423040 Injector Cup

Utilizing the Cummins 3423040 Injector Cup offers several advantages. It contributes to improved engine efficiency by ensuring consistent fuel pressure and delivery. The durable construction and precise engineering of the injector cup enhance the overall reliability and longevity of the fuel injection system. Additionally, its design helps to maintain optimal engine performance under various operating conditions.

Installation Process

Installing the Cummins 3423040 Injector Cup requires careful attention to detail to ensure a secure fit. The process involves cleaning the cylinder head surface, applying a compatible sealant if necessary, and pressing the injector cup into place using appropriate tools. It is important to follow manufacturer guidelines to avoid damage to the component or surrounding parts. Proper installation is key to ensuring the injector cup functions effectively within the fuel injection system.

Common Issues and Troubleshooting

Injector cups, including the Cummins 3423040, may encounter issues such as leaks or failures over time. Common problems can arise from wear, corrosion, or improper installation. Troubleshooting these issues involves inspecting the injector cup and surrounding components for signs of damage or wear. Addressing problems promptly can help prevent further engine damage and maintain the efficiency of the fuel injection system.

Maintenance Tips

To prolong the lifespan of the Cummins 3423040 Injector Cup, routine maintenance practices are recommended. This includes regular inspections for signs of wear or damage, cleaning the injector cup and surrounding areas to prevent buildup, and ensuring that all components within the fuel injection system are functioning correctly. Adhering to manufacturer-recommended maintenance intervals can help maintain the performance and reliability of the injector cup.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability within the automotive and heavy-duty truck industries. The company offers a wide range of products and services designed to meet the needs of customers around the world, emphasizing sustainability and efficiency in its offerings.

Cummins Injector Cup (Part 3423040) Compatibility

The Cummins Injector Cup, identified by part number 3423040, is a critical component in the fuel injection system of various Cummins engines. This part is designed to ensure efficient and precise fuel delivery, which is essential for maintaining optimal engine performance. Below is a detailed description of how this injector cup fits with the specified Cummins engines.

QSW/QSV82 Engines

The injector cup 3423040 is compatible with the QSW/QSV82 engines. These engines are known for their robust design and high power output, making them suitable for heavy-duty applications. The injector cup ensures that the fuel is delivered in a controlled manner, enhancing the engine’s efficiency and reliability.

QSW27 and QSW36 Engines

The injector cup 3423040 also fits the QSW27 and QSW36 engines. These engines are part of the Cummins QSW series, which is recognized for its versatility and durability in various industrial applications. The precise fit of the injector cup is crucial for maintaining the correct fuel-air mixture, which is vital for the engines’ performance and longevity.

QSW73 Engine

Lastly, the injector cup 3423040 is also compatible with the QSW73 engine. This engine is designed for applications that require high power and efficiency. The injector cup’s role in this engine is to ensure that the fuel is injected at the correct pressure and timing, which is essential for achieving the desired performance and fuel economy.

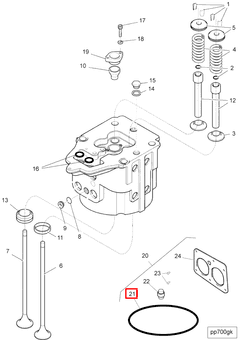

Role of Part 3423040 Injector Cup in Engine Systems

The 3423040 Injector Cup is an essential component within various engine systems, particularly in the assembly and maintenance of the cylinder head and related components. This part is integral to the proper functioning of the fuel injection system, ensuring efficient and reliable performance of the engine.

In the Assembly Head Cylinder, the Injector Cup plays a significant role by providing a secure and precise fitting for the injector within the cylinder head. This ensures that fuel is delivered accurately and consistently to the combustion chamber, which is vital for optimal engine performance.

Within the Cylinder Assembly Head, the Injector Cup contributes to the overall integrity of the assembly. It helps maintain the structural stability of the cylinder head, allowing for smooth and efficient operation of the engine.

The Cylinder Head itself relies on the Injector Cup to facilitate proper fuel injection. By ensuring a tight and secure seal, the Injector Cup prevents fuel leaks and maintains the correct fuel-air mixture, which is essential for combustion efficiency.

In a Cylinder Head Assembly, the Injector Cup is a key component that ensures all parts work in harmony. It supports the injector’s position and function, contributing to the overall reliability and performance of the cylinder head assembly.

During a Cylinder Head Overhaul, the Injector Cup is often replaced or inspected to ensure it meets the necessary standards. This is important for restoring the cylinder head to its optimal condition, ensuring that the engine operates efficiently post-overhaul.

The Head of the engine, which includes the cylinder head, depends on the Injector Cup to maintain the integrity of the fuel injection system. This is particularly important in high-performance engines where precision and reliability are paramount.

The Cylinder benefits from the Injector Cup by receiving a consistent and accurate fuel supply. This is essential for maintaining the cylinder’s performance and longevity, as well as ensuring the engine runs smoothly.

Lastly, the Mounting Insert often works in conjunction with the Injector Cup to provide additional support and stability. This ensures that the injector is held firmly in place, reducing the risk of movement or misalignment, which could affect engine performance.

Overall, the 3423040 Injector Cup is a vital component in various engine systems, playing a key role in ensuring the efficient and reliable operation of the fuel injection system within the cylinder head and related assemblies.

Conclusion

The Cummins 3423040 Injector Cup is a critical component in the fuel injection system of heavy-duty trucks, ensuring efficient and reliable engine performance. Its role in maintaining fuel pressure, providing a secure seal, and facilitating precise fuel delivery is essential for the overall efficiency and reliability of the engine. Proper installation, maintenance, and understanding of its compatibility with various Cummins engines are key to maximizing the performance and longevity of this part.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

John Dixon, Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, Cengage Learning, 2014.

↩ -

S. A. Miedema, Z. Lu, The Dynamic Behavior of a Diesel Engine, Published by Drir S. A. Miedema, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.