This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

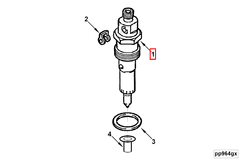

The Cummins Lubricating Oil Drain Tube, part number 3919298, is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the draining of used oil from the engine, playing a significant role in the maintenance routine of these vehicles. Proper maintenance of the oil system is vital for the longevity and performance of heavy-duty truck engines, and the drain tube is a key element in this process 1.

Function and Operation

The Lubricating Oil Drain Tube operates by providing a pathway for used oil to exit the engine during an oil change. It is connected to the oil pan and allows for the efficient removal of oil when the drain plug is removed. This component ensures that the oil is directed away from the engine and into a collection container, minimizing the risk of spills and facilitating a cleaner work environment 2.

Key Features

The design of the Lubricating Oil Drain Tube incorporates several characteristics that enhance its performance and durability. It is constructed from materials that resist corrosion and high temperatures, ensuring longevity in the demanding environment of a heavy-duty truck engine. The tube’s design may include features such as a secure fitting mechanism to prevent leaks and a flexible hose to accommodate the contours of the engine bay 3.

Benefits of Using Lubricating Oil Drain Tube

Incorporating the Lubricating Oil Drain Tube into truck maintenance routines offers several advantages. It improves the efficiency of oil changes by providing a direct and controlled path for oil to exit the engine. This can reduce the time required for maintenance tasks and lower the risk of spills, which can be hazardous and difficult to clean. Additionally, the use of a dedicated drain tube can contribute to a more organized and professional maintenance process 4.

Installation Process

Installing the Lubricating Oil Drain Tube requires careful attention to ensure a proper fit and function. The process involves securing the tube to the oil pan with the provided fittings, ensuring that all connections are tight to prevent leaks. It is important to follow the manufacturer’s instructions closely and to use the appropriate tools for the installation. After installation, it is recommended to perform a test to confirm that the tube is functioning correctly and that there are no leaks 5.

Maintenance and Troubleshooting

To ensure the longevity and performance of the Lubricating Oil Drain Tube, regular maintenance is necessary. This includes checking for signs of wear or damage, ensuring that all connections remain secure, and cleaning the tube as needed. Common issues that may arise include leaks, which can often be resolved by tightening connections or replacing worn components. It is also important to monitor the tube for any signs of corrosion or material degradation 6.

Safety Considerations

When working with the Lubricating Oil Drain Tube, it is important to observe safety practices to protect oneself and the environment. This includes allowing the engine to cool before beginning maintenance to avoid burns from hot oil. Used oil should be handled carefully and disposed of in accordance with local regulations to prevent environmental contamination. Personal protective equipment, such as gloves and safety glasses, should be worn during maintenance tasks 7.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes components and systems for on-highway, off-highway, and stationary applications, serving a variety of industries worldwide. Cummins’ dedication to advancing technology and sustainability is evident in its continuous investment in research and development 8.

Compatibility

The Lubricating Oil Drain Tube, identified by part number 3919298, is compatible with several Cummins engine models, including but not limited to the 6B5.9 Series. This part is designed to facilitate the drainage of used lubricating oil from the engine’s oil pan, ensuring that the engine operates smoothly and efficiently by allowing the old oil to be replaced with fresh oil 9.

Role in Engine Systems

The Lubricating Oil Drain Tube plays a significant role in the overall functionality and maintenance of engine systems. Its proper integration and maintenance are key to ensuring the engine operates at peak performance. The tube works in conjunction with various engine components, including injector systems, onboard spares, performance parts, and maintenance kits, to maintain clean oil and ensure consistent lubrication 10.

Conclusion

The Cummins Lubricating Oil Drain Tube, part number 3919298, is a vital component in the maintenance and operation of heavy-duty truck engines. Its design and functionality contribute to the efficiency and longevity of engine systems, making it an essential part of regular maintenance routines.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Bosch GmbH, R. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5504625, Engine: QSK60 CM2350 K135.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5504625, Engine: QSK60 CM2350 K135.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5504625, Engine: QSK60 CM2350 K135.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5504625, Engine: QSK60 CM2350 K135.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5504625, Engine: QSK60 CM2350 K135.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5504625, Engine: QSK60 CM2350 K135.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.