The Injector Fuel Supply Tube, part number 3964141, manufactured by Cummins, is a component designed for use in commercial truck engines. Cummins, a well-established name in the engine manufacturing industry, produces this part to ensure efficient fuel delivery within diesel engines. This Cummins part is integral to the fuel system, contributing to the engine’s overall performance and efficiency.

Basic Concepts of Injector Fuel Supply Tubes

An Injector Fuel Supply Tube is a component within the fuel system of a diesel engine. Its primary function is to deliver fuel from the fuel rail to the injector. This ensures that the injector receives a consistent and adequate supply of fuel, which is essential for the combustion process. The tube plays a role in maintaining the pressure and flow of fuel, which directly affects the engine’s operation and efficiency 1.

Purpose of the Injector Fuel Supply Tube

The Injector Fuel Supply Tube is designed to facilitate the delivery of fuel from the fuel rail to the injector in a commercial truck engine. By ensuring a steady and pressurized flow of fuel, it contributes to the efficient operation of the engine. This part is engineered to withstand the high pressures and temperatures within the fuel system, ensuring reliable performance over time 2.

Key Features

The Injector Fuel Supply Tube is constructed from materials that offer durability and resistance to the high pressures and temperatures found within diesel engines. Its design includes features that enhance its performance, such as precise engineering to ensure a secure fit within the fuel system. Additionally, the tube may incorporate elements that reduce the risk of fuel leaks, contributing to safer and more efficient engine operation 3.

Benefits

The use of the Injector Fuel Supply Tube offers several advantages. It contributes to improved fuel delivery efficiency, which can enhance engine performance. Additionally, by ensuring a consistent fuel supply, it may play a role in optimizing fuel economy. The durable construction of the tube also contributes to its longevity, reducing the need for frequent replacements 4.

Installation and Integration

Installing the Injector Fuel Supply Tube into the fuel system of a commercial truck requires careful attention to ensure a proper fit and secure connection. It is important to follow manufacturer guidelines to avoid issues such as fuel leaks or inadequate fuel pressure. Integration into the fuel system should be performed by qualified professionals to ensure optimal performance and safety.

Maintenance and Troubleshooting

Regular maintenance of the Injector Fuel Supply Tube is important to ensure its continued efficient operation. This includes periodic inspections for signs of wear, damage, or leaks. Common issues may include blockages or restrictions within the tube, which can affect fuel flow. Troubleshooting tips may involve checking for proper connections, ensuring there are no obstructions, and verifying that the tube is free from damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range includes engines, components, and technologies that power a variety of applications, from on-highway to off-highway and stationary uses. The Injector Fuel Supply Tube is a testament to Cummins’ commitment to providing high-quality, reliable components for the engines it manufactures.

Compatibility with Specific Engine Models

-

ISC CM2150, ISL9 CM2150 SN, QSL8.9 CM2150 L141

The Injector Fuel Supply Tube fits seamlessly with these engines, ensuring that the fuel is delivered consistently and accurately to the injectors. This is crucial for maintaining the engine’s power output and efficiency.

-

ISC CM850, QSC8.3 CM850(CM2850), QSL9 CM850(CM2850)

Similarly, this part is also compatible with these engines. The design of the tube ensures that it can handle the specific demands of these engines, providing a reliable fuel supply that supports their operational needs.

Importance of the Injector Fuel Supply Tube

The Injector Fuel Supply Tube is integral to the fuel system’s integrity. It connects the fuel supply line to the injectors, ensuring that fuel is delivered at the correct pressure and flow rate. This is vital for the engine’s combustion process, as any disruption in fuel delivery can lead to performance issues and potential engine damage.

Installation and Maintenance

Proper installation of the Injector Fuel Supply Tube is essential to ensure it functions correctly. It should be securely attached to both the fuel supply line and the injectors, with no leaks or loose connections. Regular maintenance checks should be performed to inspect for wear, damage, or blockages, which can affect the engine’s performance.

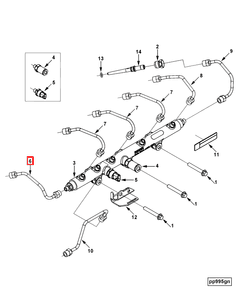

Role of Part 3964141 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, part number 3964141, is an integral component in the fuel delivery system of an engine. It facilitates the precise and efficient transfer of fuel from the fuel manifold to the individual injectors. This part ensures that each injector receives a consistent fuel supply, which is essential for the engine’s performance and efficiency.

Integration with Engine Components

-

Fuel Manifold: The Injector Fuel Supply Tube connects directly to the fuel manifold, which acts as a distribution hub for fuel. The tube extends from the manifold to each injector, ensuring a streamlined fuel path.

-

Injector Plumbing: This tube is a key element in the injector plumbing system. It provides a dedicated pathway for fuel, minimizing the risk of fuel line restrictions or leaks that could affect engine performance.

-

Cylinder Head: Positioned above the cylinder head, the Injector Fuel Supply Tube works in conjunction with the injectors mounted on the cylinder head. This arrangement allows for direct fuel delivery to the combustion chambers.

-

Injectors: The primary function of the Injector Fuel Supply Tube is to supply fuel to the injectors. Each injector is responsible for spraying atomized fuel into the combustion chamber at the precise moment required for optimal combustion.

-

Camshaft and Connecting Rod and Piston: Although the Injector Fuel Supply Tube does not directly interact with the camshaft, connecting rod, or piston, its role in ensuring proper fuel delivery indirectly supports the efficient operation of these components. Consistent fuel supply leads to more reliable combustion, which in turn supports the smooth operation of the camshaft, connecting rod, and piston.

Performance Implications

The Injector Fuel Supply Tube plays a significant role in maintaining the engine’s performance. By ensuring a steady and precise fuel supply to each injector, it helps in achieving the desired air-fuel ratio, which is vital for engine efficiency, power output, and emissions control.

Conclusion

The Injector Fuel Supply Tube, part number 3964141, is a vital component in the fuel delivery system, working seamlessly with the fuel manifold, injector plumbing, cylinder head, and injectors to enhance engine performance and reliability. Its compatibility with specific engine models ensures efficient and reliable fuel supply, supporting the engine’s performance and longevity.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones & Bartlett Learning.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.