This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

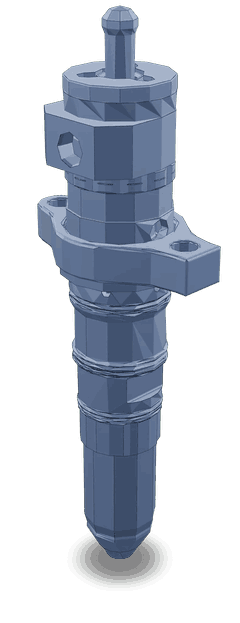

The Cummins 4062311 Front Engine Support is a component designed to enhance the structural integrity and performance of commercial truck engines. This part is integral to the operation of trucks, providing necessary support to the engine assembly and contributing to the overall efficiency and reliability of the vehicle 1.

Purpose and Function

The Cummins 4062311 Front Engine Support plays a role in the truck’s engine assembly by securing the engine to the truck’s frame. This support is vital for maintaining the alignment and stability of the engine, which in turn affects the performance and longevity of the engine. By providing a sturdy mounting point, it helps distribute the engine’s weight and absorb vibrations, which can occur during operation 2.

Key Features

The Cummins 4062311 Front Engine Support is constructed from high-strength materials, ensuring durability and resistance to the stresses encountered in commercial truck operations. Its design incorporates precise engineering to fit securely with the engine and frame, featuring mounting points and brackets that facilitate easy installation and robust attachment. Additionally, the support may include features such as vibration dampening elements to enhance engine performance and reduce wear on the engine and its mounts 3.

Benefits

Utilizing the Cummins 4062311 Front Engine Support offers several advantages. It contributes to improved engine stability, which can lead to more consistent engine performance over time. The enhanced durability of the support means it can withstand the rigors of commercial use, potentially reducing the need for frequent replacements. Furthermore, by ensuring the engine remains properly aligned and secure, it may contribute to overall truck performance, including fuel efficiency and reduced maintenance costs.

Installation Process

Installing the Cummins 4062311 Front Engine Support requires careful attention to ensure proper fitting. The process involves securing the support to the truck’s frame using the provided mounting hardware. It is important to follow manufacturer guidelines for torque specifications and alignment to ensure the support is correctly installed. Tools required may include a torque wrench and socket set, among others, to facilitate a secure and precise installation.

Maintenance and Troubleshooting

Maintaining the Cummins 4062311 Front Engine Support involves regular inspections for signs of wear or damage, such as cracks or excessive corrosion. Common issues may include loosening of the mounting hardware or wear on the support itself. Troubleshooting steps include tightening any loose components and assessing the condition of the support for any necessary repairs or replacements. Adhering to recommended maintenance schedules can help prolong the component’s lifespan and ensure continued reliable performance.

Compatibility and Applications

The Cummins 4062311 Front Engine Support is designed for use in specific types of trucks and engine models. Its applicability varies across different commercial truck settings, making it a versatile component for enhancing engine support in compatible vehicles.

Safety Considerations

When working with the Cummins 4062311 Front Engine Support, it is important to observe safety guidelines and precautions. This includes ensuring the truck is properly supported on jack stands during installation or maintenance, wearing appropriate personal protective equipment, and following all manufacturer instructions to prevent injury or damage to the vehicle.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation in engine components. With a rich history of developing reliable and efficient engine solutions, Cummins continues to be a trusted name among commercial truck operators and manufacturers alike.

Cummins Front Engine Support Part 4062311

The Cummins Front Engine Support part 4062311 is a component designed to provide structural integrity and stability to the engine. This part is integral to the engine’s mounting system, ensuring that the engine remains securely fastened within the engine bay.

Application in K50 Engines

The K50 engine series, known for its robust performance and reliability, utilizes the Front Engine Support part 4062311 to maintain the engine’s alignment and reduce vibrations. This support is engineered to withstand the stresses and forces exerted during engine operation, contributing to the longevity and efficiency of the engine.

Grouping with Other Cummins Engines

The part 4062311 is not exclusive to the K50 engine series. It is also compatible with other Cummins engine models, where it serves the same fundamental purpose of providing front engine support. This versatility makes it a valuable component across various engine applications, ensuring consistent performance and reliability.

Importance in Engine Mounting

The Front Engine Support part 4062311 plays a role in the engine mounting system. By securing the engine at the front, it helps to distribute the engine’s weight evenly and minimizes the risk of misalignment. This support is essential for maintaining the engine’s operational efficiency and preventing potential damage from excessive movement or vibration.

Role of Part 4062311 Front Engine Support in Performance Parts

The part 4062311 Front Engine Support is integral to the structural integrity and performance of various engine systems. It provides a stable mounting point for the engine, ensuring that it remains securely in place during operation. This stability is essential for the proper functioning of performance-oriented components.

Integration with Performance Parts

-

Turbochargers: The Front Engine Support is vital for maintaining the alignment of turbochargers. Proper alignment ensures efficient airflow and reduces the risk of turbo lag, which is important for maximizing engine performance.

-

Intercoolers: When intercoolers are mounted to the front of the engine, the Front Engine Support helps in maintaining their position and orientation. This is important for optimal cooling efficiency, which directly affects engine power and reliability.

-

Cold Air Intakes: For cold air intake systems, the Front Engine Support ensures that the intake path remains unobstructed and correctly aligned. This alignment is key to drawing in cooler air, which enhances combustion efficiency and overall engine performance.

-

Exhaust Systems: The support structure provided by the Front Engine Support is also beneficial for exhaust manifolds and downpipes. It helps in maintaining the correct exhaust flow path, which is essential for reducing backpressure and improving engine efficiency.

-

Engine Mounts: The Front Engine Support works in conjunction with other engine mounts to distribute the engine’s weight and vibrations evenly. This balance is crucial for the longevity of performance parts and the overall drivability of the vehicle.

-

Ancillary Components: Other performance parts such as oil coolers, transmission coolers, and radiators also benefit from the stability provided by the Front Engine Support. Proper mounting ensures these components operate within their designed parameters, contributing to the vehicle’s overall performance and reliability.

Conclusion

The Cummins 4062311 Front Engine Support is a critical component for the structural integrity and performance of commercial truck engines. Its role in securing the engine, distributing weight, and absorbing vibrations contributes to the overall efficiency, reliability, and longevity of the vehicle. Proper installation, maintenance, and understanding of its compatibility and applications are essential for maximizing the benefits of this Cummins part.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩ -

Sean Bennett, Modern Diesel Technology Light Duty Diesels, Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.