This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector 4088426 is a component designed for use in commercial truck engines, manufactured by Cummins Inc. Cummins is renowned for its high-quality diesel engine components, and this injector is no exception. It plays a significant role in the efficient operation of truck engines, contributing to their performance and reliability.

Basic Concepts of Fuel Injectors

Fuel injectors are devices that deliver fuel into the combustion chamber of diesel engines. They operate by atomizing fuel into fine particles, which enhances combustion efficiency and engine performance. The precise control of fuel delivery by injectors allows for optimal fuel-air mixture, leading to improved power output and fuel economy 1.

Purpose of the Cummins Injector 4088426

This Cummins part is integral to the fuel delivery and combustion process in truck engines. It ensures that fuel is delivered at the correct pressure and timing, which is crucial for efficient combustion. This injector contributes to the overall performance of the engine by ensuring that fuel is atomized properly, leading to a more complete burn and reduced emissions 2.

Key Features

The Cummins Injector 4088426 is characterized by its robust design and the use of high-quality materials. It incorporates advanced technological features that enhance its performance, such as precise fuel metering and durable construction. These features ensure that the injector can withstand the demanding conditions of commercial truck operation while maintaining high efficiency.

Benefits of Using Cummins Injector 4088426

Employing this injector in commercial trucks offers several advantages. It contributes to improved fuel efficiency by ensuring optimal fuel delivery. This injector also enhances engine performance through precise fuel atomization, leading to more efficient combustion. Additionally, it aids in emissions reduction, aligning with environmental regulations and promoting sustainable operation 3.

Installation and Integration

Proper installation of the Cummins Injector 4088426 is vital for its effective operation. It requires careful alignment and secure fitting within the engine system. Specific requirements may vary depending on the truck engine model, necessitating adherence to manufacturer guidelines to ensure compatibility and optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the Cummins Injector 4088426 is essential to sustain its performance. This includes routine inspections, cleaning to remove any deposits, and checking for wear or damage. Common troubleshooting tips involve addressing issues such as inconsistent fuel delivery or engine misfires, which may indicate the need for injector cleaning or replacement.

Performance Enhancements

The Cummins Injector 4088426 contributes to overall engine performance by enhancing power output, fuel economy, and reliability. Its precise fuel delivery ensures that the engine operates efficiently, leading to better performance metrics and reduced operational costs for fleet operators.

Environmental Impact

The use of the Cummins Injector 4088426 has positive environmental implications. By ensuring efficient fuel combustion, it helps in reducing emissions, which is beneficial for air quality. Improved fuel efficiency also means lower fuel consumption, contributing to reduced carbon footprint and promoting sustainable transportation practices.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a strong reputation in the industry for innovation and quality. The company has a long history of developing reliable and efficient engine components, demonstrating a commitment to advancing diesel technology and meeting the evolving needs of commercial transportation.

Cummins Injector 4088426 Compatibility

The Cummins injector part number 4088426 is designed to be compatible with specific models within the Cummins engine lineup. This injector is engineered to meet the stringent demands of the QSK45 CM500 and QSK60 CM500 engines, ensuring optimal performance and reliability.

QSK45 CM500

For the QSK45 CM500 engine, the injector 4088426 is a critical component that ensures precise fuel delivery. This engine is known for its robust performance and efficiency, and the injector plays a pivotal role in maintaining these characteristics. The injector’s design allows for accurate fuel atomization, which is essential for the engine’s combustion process.

QSK60 CM500

Similarly, the QSK60 CM500 engine benefits from the use of the injector 4088426. This engine, like the QSK45, requires a high level of precision in fuel delivery to operate efficiently. The injector’s compatibility with the QSK60 ensures that the engine can achieve its full potential in terms of power output and fuel economy. The injector’s construction and design are tailored to withstand the high pressures and temperatures associated with this engine model.

Compatibility and Performance

The injector 4088426 is engineered to fit seamlessly into both the QSK45 CM500 and QSK60 CM500 engines. Its design ensures that it can handle the specific demands of these engines, providing consistent and reliable performance. The injector’s compatibility with these engines is a testament to Cummins’ commitment to quality and precision in their engine components.

By using the injector 4088426 in these engines, users can expect enhanced performance, improved fuel efficiency, and reduced emissions. The injector’s role in the fuel delivery system is crucial, as it directly impacts the engine’s overall efficiency and power output.

Role of Part 4088426 Injector in Engine Systems

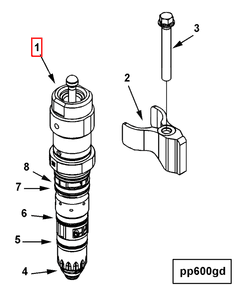

Part 4088426 Injector is integral to the efficient operation of engine systems, particularly in fuel delivery and combustion processes. This component works in concert with several other parts to ensure optimal engine performance.

Fuel Delivery System

The Injector plays a significant role in the fuel delivery system by precisely metering and delivering fuel into the combustion chamber. It interfaces with the fuel rail, which supplies pressurized fuel, and the engine control unit (ECU), which regulates the timing and duration of fuel injection. The Injector’s accurate fuel delivery helps maintain the correct air-fuel ratio, which is essential for efficient combustion and overall engine performance.

Combustion Process

During the combustion process, the Injector sprays atomized fuel into the cylinder at the precise moment dictated by the ECU. This timing is crucial for igniting the fuel-air mixture efficiently. The Injector’s design ensures that the fuel is evenly distributed, promoting complete combustion and reducing emissions. The interaction between the Injector and the spark plug (in gasoline engines) or the glow plug (in diesel engines) is seamless, contributing to smooth engine operation.

Emission Control System

Part 4088426 Injector also contributes to the emission control system by ensuring that fuel is burned as completely as possible. Incomplete combustion can lead to higher emissions of harmful pollutants. The Injector’s role in providing a fine fuel spray helps minimize unburned fuel, thereby reducing emissions. It works in tandem with the oxygen sensor and the catalytic converter to maintain low emission levels.

Engine Performance

The performance of the engine is directly influenced by the Injector’s ability to deliver fuel accurately and consistently. In high-performance engines, the Injector must handle increased fuel demands without compromising precision. The Injector’s performance is monitored by the ECU, which makes real-time adjustments to ensure that the engine operates within its optimal parameters. This dynamic interaction between the Injector and the ECU is vital for achieving peak engine performance.

Maintenance and Durability

Regular maintenance of Part 4088426 Injector is essential to ensure its longevity and consistent performance. Clogged or malfunctioning Injectors can lead to poor fuel economy, reduced power, and increased emissions. Therefore, periodic cleaning and inspection of the Injector are recommended to maintain engine efficiency and reliability.

Conclusion

In summary, Part 4088426 Injector is a key component in the engine system, playing a vital role in fuel delivery, combustion, emission control, and overall engine performance. Its precise operation, in coordination with other engine parts, ensures that the engine runs smoothly and efficiently.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.