This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

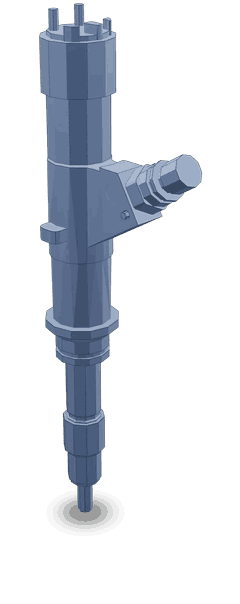

The Cummins 4307475 Injector is a component designed for use in commercial trucks, specifically within Cummins diesel engines. Its purpose is to deliver fuel into the combustion chamber with precision, ensuring optimal engine performance. The significance of this injector lies in its ability to enhance fuel efficiency, improve engine power, and contribute to the overall reliability of the vehicle 2.

Basic Concepts of Fuel Injectors

Fuel injectors are devices used in diesel engines to spray fuel into the combustion chamber at high pressure. They play a role in the fuel delivery system by atomizing fuel into fine particles, which mix with air to create a combustible mixture. The efficiency of fuel injectors directly impacts engine performance, fuel economy, and emissions 1.

Purpose of the Cummins 4307475 Injector

This Cummins part functions within the fuel system to deliver a measured amount of fuel into the engine’s cylinders. It contributes to engine performance by ensuring that fuel is injected at the precise moment and in the correct quantity, which is vital for combustion efficiency and power output. This injector is engineered to work seamlessly with Cummins engines, enhancing their operational capabilities 2.

Key Features

The Cummins 4307475 Injector incorporates several design elements and materials that enhance its performance and durability. It features a robust construction with precision-machined components to ensure accurate fuel delivery. The use of high-quality materials contributes to its resistance against wear and corrosion, while technological advancements such as electronic control systems allow for fine-tuning of fuel injection parameters 2.

Benefits

Utilizing the Cummins 4307475 Injector offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is used effectively during combustion. Enhanced engine performance is another benefit, as the precise fuel delivery leads to more consistent power output. Additionally, the reliability of the injector plays a role in reducing downtime and maintenance costs for commercial truck operators 2.

Installation and Integration

Proper installation of the Cummins 4307475 Injector involves several steps to ensure it functions correctly within the engine system. Preparations may include cleaning the fuel system and inspecting other components for compatibility. Integration with other engine parts requires attention to detail to maintain the integrity of the fuel delivery system and ensure that the injector operates within the engine’s specified parameters 2.

Performance and Efficiency

The Cummins 4307475 Injector contributes to the overall performance and efficiency of the engine through its precise fuel delivery and combustion efficiency. By atomizing fuel into fine particles and injecting it at the optimal time, it plays a role in maximizing the energy released during combustion, which translates to better engine performance and fuel economy 2.

Troubleshooting and Maintenance

Common issues with the Cummins 4307475 Injector may include clogged nozzles or electronic malfunctions. Troubleshooting steps involve inspecting the injector for physical damage, cleaning or replacing nozzles as necessary, and checking the electronic control system for proper function. Regular maintenance practices, such as cleaning the fuel system and monitoring injector performance, help ensure the longevity and optimal performance of the injector 2.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of engines and components designed to meet the demanding requirements of commercial transportation, demonstrating a commitment to excellence and customer satisfaction 2.

Cummins Injector 4307475 Compatibility

The Cummins injector part number 4307475 is designed to fit a range of engine models. Below is a detailed description of its compatibility across various engines:

ISG11 CM2880 G108 and ISG12 CM2880 G107

The injector 4307475 is compatible with the ISG11 CM2880 G108 and ISG12 CM2880 G107 engines. These engines are part of the Cummins Industrial and Small Gas (ISG) series, known for their reliability and efficiency in industrial applications.

QSG12 CM2880 G112

This injector also fits the QSG12 CM2880 G112 engine. The QSG series is designed for quick-start applications, providing robust performance in demanding environments.

QSG12/X12 CM2350 G110

The injector 4307475 is suitable for the QSG12/X12 CM2350 G110 engine. This model is part of the Cummins Quick-Start Gas (QSG) series, which is engineered for rapid deployment and efficient operation.

X12 CM2350 X119B

The injector is also compatible with the X12 CM2350 X119B engine. This engine is designed for high-performance applications, ensuring optimal fuel efficiency and power output.

X12 CM2670 X121B

The injector 4307475 fits the X12 CM2670 X121B engine. This engine is part of the Cummins X Series, which is known for its durability and high-performance capabilities.

Z14 CM2670 Z103B

Lastly, the injector is compatible with the Z14 CM2670 Z103B engine. This engine is designed for heavy-duty applications, providing exceptional power and reliability.

Role of Part 4307475 Injector in Engine Systems

The part 4307475 injector is an essential component in the fuel delivery system of an engine, working in concert with several other key components to ensure optimal engine performance.

Interaction with the Cylinder Head

The injector is strategically positioned within the cylinder head, a critical part of the engine’s upper assembly. Its primary function is to deliver a precise amount of fuel into the combustion chamber at the exact moment required for efficient combustion. The cylinder head houses the injector, providing a secure and stable environment for it to operate. The injector’s nozzle is typically aligned with the intake ports in the cylinder head, ensuring that the fuel is sprayed directly into the path of the incoming air, promoting better fuel-air mixing and more complete combustion 2.

Integration with the Cylinder Top Level Assembly Head

In engines where the cylinder top level assembly head is used, the injector plays a pivotal role. This assembly often includes components such as the valvetrain, spark plugs (in gasoline engines), and the injector itself. The injector must be meticulously aligned with the other components within this assembly to maintain the correct fuel delivery timing and spray pattern. The synchronization between the injector and the valvetrain ensures that fuel is introduced into the combustion chamber just before the intake valve opens, maximizing the efficiency of the fuel-air mixture 2.

Fuel Delivery and Combustion Process

The injector’s role extends beyond mere fuel delivery; it is integral to the combustion process itself. By atomizing the fuel into fine droplets, the injector enhances the surface area of the fuel, allowing for quicker and more thorough mixing with the air. This results in a more consistent and controlled combustion event, which is essential for maintaining engine performance, reducing emissions, and ensuring smooth operation 2.

Conclusion

In summary, the part 4307475 injector is a vital component that interacts closely with the cylinder head and the cylinder top level assembly head to deliver fuel precisely when and where it is needed. This ensures efficient combustion, optimal engine performance, and reduced emissions. The injector’s robust construction, precision-machined components, and advanced electronic control systems contribute to its reliability and efficiency, making it a valuable asset for commercial truck operators 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.