4331970

Injector Fuel Supply Tube

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Fuel Supply Tube, part number 4331970, is a critical component in the fuel system of heavy-duty trucks. Manufactured by Cummins Inc., a prominent figure in the diesel engine and components industry, this part ensures efficient fuel delivery from the tank to the injectors. Its role in maintaining the performance and reliability of Cummins engines highlights its importance in the automotive sector 1.

Function and Operation

This Cummins part operates by facilitating the transfer of fuel from the tank to the injectors within the engine system. The Injector Fuel Supply Tube ensures a consistent and pressurized flow of fuel, which is essential for the combustion process in diesel engines. Its design allows it to withstand the high pressures and temperatures inherent in fuel systems, ensuring a reliable supply of fuel to the injectors 2.

Key Features

The design and construction of the Injector Fuel Supply Tube are tailored for durability and efficiency. Crafted from high-quality materials, it is resistant to corrosion and wear, ensuring longevity in demanding environments. Its construction includes precise engineering to maintain fuel pressure and prevent leaks, enhancing the overall performance of the fuel system 3.

Benefits

The Injector Fuel Supply Tube offers several advantages, including improved fuel delivery efficiency and reliability. Its design contributes to the consistent performance of Cummins engines, ensuring that fuel is delivered under the right conditions for optimal combustion. Additionally, its compatibility with Cummins engines ensures seamless integration and operation within the fuel system 4.

Installation and Maintenance

Proper installation of the Injector Fuel Supply Tube is crucial for its effective operation. It should be securely fitted within the fuel system to prevent leaks and ensure a consistent fuel flow. Regular maintenance, including inspections for wear and corrosion, is recommended to maintain its performance. Common issues may include blockages or leaks, which can be addressed through routine checks and timely replacements if necessary.

Troubleshooting

Common problems associated with the Injector Fuel Supply Tube may include fuel leaks, blockages, or reduced fuel pressure. Diagnostic procedures involve checking for visible signs of damage or wear, testing fuel pressure, and inspecting connections for tightness. Solutions may range from cleaning or repairing the tube to replacing it if significant damage is detected.

Compatibility and Applications

The Injector Fuel Supply Tube is designed for use with specific Cummins engine models, ensuring compatibility and optimal performance. Its applications extend to various types of heavy-duty trucks, where it plays a role in the efficient operation of the fuel system. Understanding its compatibility is key to ensuring it functions correctly within the intended engine and vehicle systems.

Safety Considerations

When handling and working with the Injector Fuel Supply Tube, it is important to follow safety precautions to prevent accidents. This includes working in a well-ventilated area, wearing appropriate personal protective equipment, and ensuring that the fuel system is depressurized before any maintenance or repair work is undertaken. Adhering to these guidelines helps ensure safe operation and handling of the component.

Environmental Impact

The use of the Injector Fuel Supply Tube contributes to fuel efficiency and emissions reduction in heavy-duty trucks. By ensuring a consistent and efficient fuel delivery, it plays a part in optimizing engine performance, which can lead to lower fuel consumption and reduced emissions. This aligns with broader efforts to improve the environmental performance of diesel engines.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the automotive industry, Cummins is known for its innovation, quality, and commitment to customer satisfaction. Its product offerings span across various sectors, with a particular focus on diesel engines and components for heavy-duty applications.

Compatibility with Cummins Engines

The Injector Fuel Supply Tube, part number 4331970, is compatible with the following Cummins engine models:

- QSK95 CM2350 K111

- QSK95 CM2350 K113

These engines are part of Cummins’ QSK series, known for their robust design and reliability in various industrial and power generation applications. This Cummins part is engineered to fit seamlessly into the fuel systems of these engines, ensuring a secure and leak-free connection.

Installation and Maintenance

Proper installation of the Injector Fuel Supply Tube is essential to prevent fuel leaks and ensure optimal engine performance. Technicians should follow the manufacturer’s guidelines for installation, which typically include:

- Ensuring all connections are tight and secure.

- Using the correct tools and techniques to avoid damaging the fuel lines or connectors.

- Regularly inspecting the fuel supply tube for signs of wear or damage.

Maintaining the Injector Fuel Supply Tube is crucial for the longevity and efficiency of the engine. Regular inspections and timely replacements of worn or damaged parts can prevent potential engine failures and ensure consistent performance.

Role of Part 4331970 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 4331970, is an integral component in the fuel delivery system of an engine. This tube facilitates the conveyance of fuel from the fuel supply system to the injectors, ensuring a consistent and regulated flow of fuel necessary for combustion.

In the context of plumbing, the Injector Fuel Supply Tube acts as a conduit, linking various components of the fuel system. It interfaces with the fuel rail, which distributes fuel to individual injectors. The tube’s design allows it to withstand the pressures and temperatures inherent in fuel systems, ensuring reliable performance.

Regarding the fuel supply, the tube plays a significant role in maintaining the integrity of the fuel as it travels from the fuel tank to the injectors. It is designed to prevent leaks and ensure that fuel is delivered at the correct pressure and volume. This is essential for the injectors to atomize the fuel properly, which is a key factor in efficient combustion and overall engine performance.

The Injector Fuel Supply Tube also contributes to the system’s ability to handle varying fuel demands. During periods of high engine load, the tube must deliver increased volumes of fuel without compromising pressure or flow rate. Conversely, during idle or low-load conditions, it must maintain a steady, minimal flow to keep the engine running smoothly.

Conclusion

In summary, the Injector Fuel Supply Tube (part 4331970) is a vital link in the fuel delivery chain, ensuring that fuel is transported efficiently and reliably from the fuel supply to the injectors, thereby supporting optimal engine operation.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

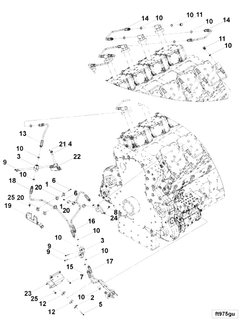

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 2 | 3865398 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.